An integrated structure of gas valve and pressure switch

A pressure switch and air valve technology, applied in the field of vehicle gearboxes, can solve the problems that the air circuit control valve and the pressure switch are not in the same position, affect the shifting feel, and have complex structure, so as to reduce the neutral positioning feel, reduce processing, Reduce the effect of part machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

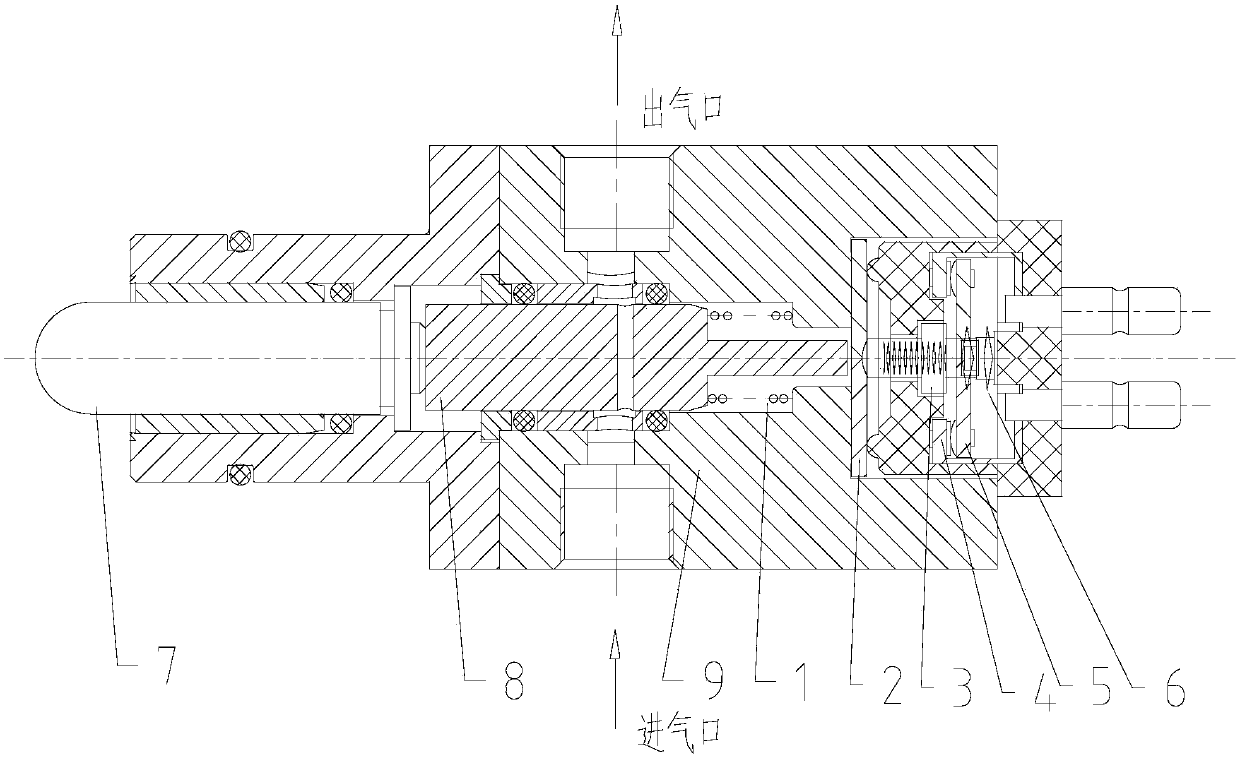

[0017] Such as figure 1 As shown, the integrated structure of the air valve and the pressure switch includes a static piece 4, a moving piece 5, a contact 7, a piston 8 and a valve seat 9;

[0018] The contact 7, the piston 8, the static piece 4 and the moving piece 5 are all installed in the valve seat 9, one end of the piston 8 is connected with the contact 7, and the other end is in indirect contact with the moving piece 5, the contact 7 and the piston 8 can be positioned on the valve seat. 9 moves in the axial direction, the valve seat 9 is provided with an air inlet and an exhaust port, the piston 8 is provided with an air passage, and when the piston 8 moves axially, the air inlet and the exhaust port of the valve seat 9 are switched on and off. There is a first spring 1 between the piston 8 and the valve seat 9. In the free state, the first spring 1 keeps the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com