Bend tube detection device and application thereof

A detection device and pipe bending technology, which is applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems of complex size chain, heavy detection workload, and many arcs of pipe fittings, so as to improve processing efficiency, improve service life, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

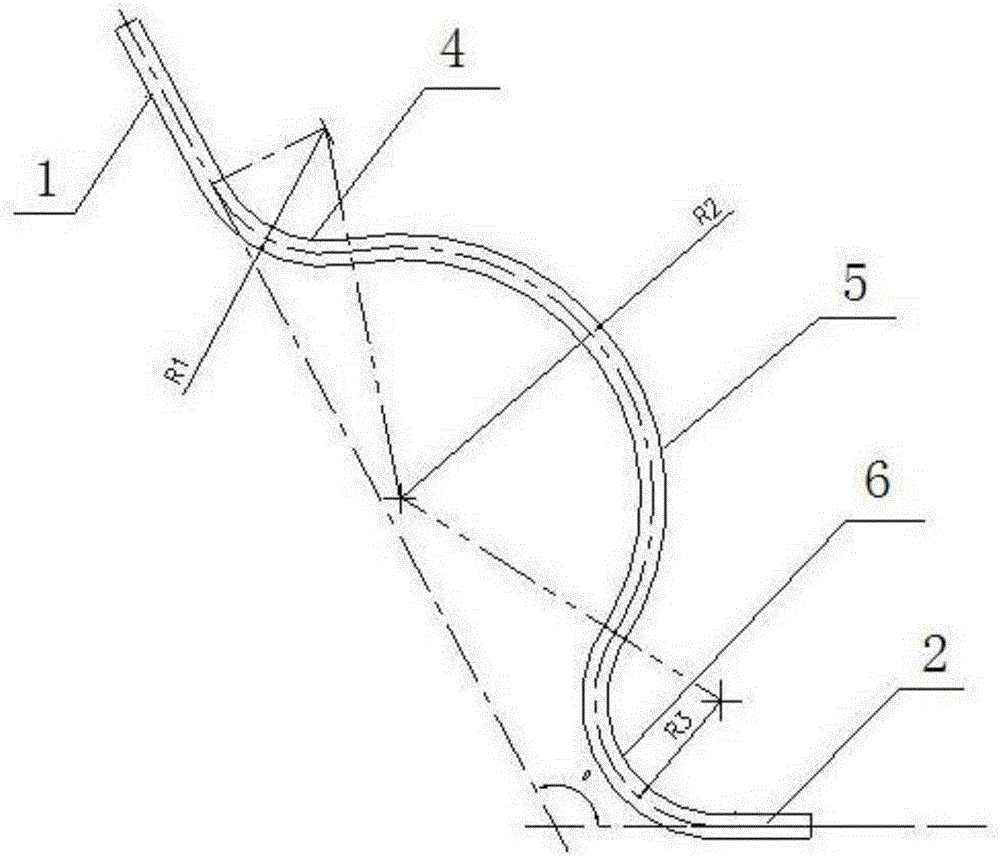

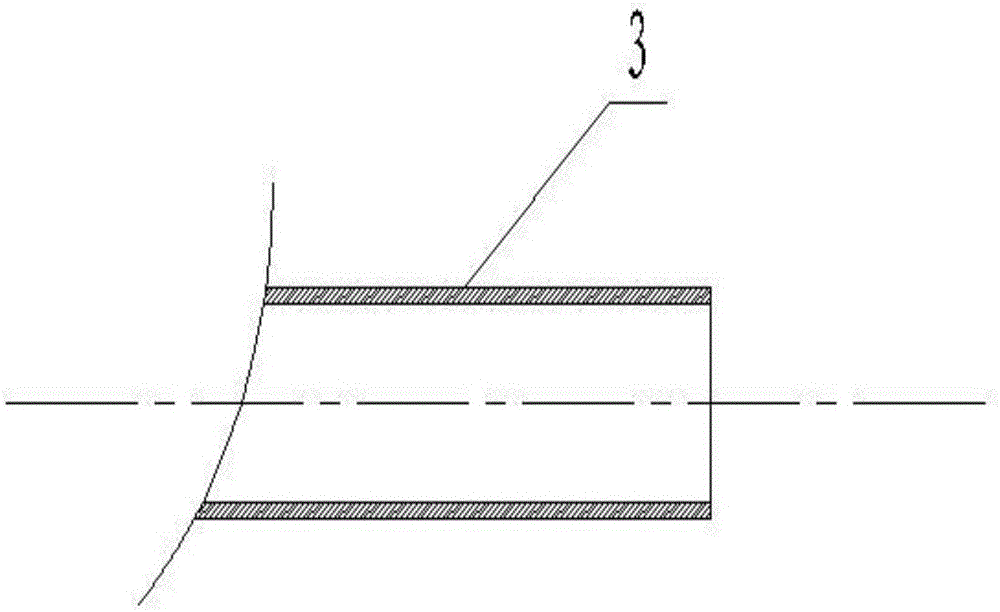

[0019] The present embodiment is 3 circular arcs, but the present invention is not limited to 3 circular arcs, such as figure 1 and figure 2 As shown, the copper tube, or steel tube, or stainless steel tube is bent; the thickness of the copper tube, or steel tube, or stainless steel tube is 2-3mm, and it also includes the extension end 1 and the tail end 2, among which the three arcs The R1, R2 and R3 are 3.2mm, 7mm and 3.2mm respectively; the central angle of the first arc is 60°, the central angle of the second arc is 120°, and the central angle of the third arc is 130°. The surfaces of the end 1, the tail end 2 and the first arc, the second arc and the third arc are all provided with a 0.2-0.5 mm thick anti-friction layer 3, and the anti-friction layer 3 includes carbon nanotubes and nanocomposite oxides mixture;

[0020] In practice, as a casting mold and a detection and comparison tool, as a casting mold, the arc is selected according to the required casting arc pipe, ...

Embodiment 2

[0022] The present embodiment is 3 circular arcs, but the present invention is not limited to 3 circular arcs, such as figure 1 and figure 2 As shown, the copper tube, or steel tube, or stainless steel tube is bent; the thickness of the copper tube, or steel tube, or stainless steel tube is 2-3mm, and it also includes the extension end 1 and the tail end 2, among which the three arcs The R1, R2 and R3 are 3.2mm, 7mm and 3.2mm respectively; the central angle of the first arc is 60°, the central angle of the second arc is 120°, and the central angle of the third arc is 130°. The surfaces of the end 1, the tail end 2 and the first arc, the second arc and the third arc are all provided with a 0.2-0.5 mm thick anti-friction layer 3, and the anti-friction layer 3 includes carbon nanotubes and nano-inorganic materials. mixture;

[0023] In practice, as a casting mold and a detection and comparison tool, as a casting mold, the arc is selected according to the required casting arc p...

Embodiment 3

[0025] The present embodiment is 3 circular arcs, but the present invention is not limited to 3 circular arcs, such as figure 1 and figure 2 As shown, the copper tube, or steel tube, or stainless steel tube is bent; the thickness of the copper tube, or steel tube, or stainless steel tube is 2-3mm, and it also includes the extension end 1 and the tail end 2, among which the three arcs The R1, R2 and R3 are 3.2mm, 7mm and 3.2mm respectively; the central angle of the first arc is 60°, the central angle of the second arc is 120°, and the central angle of the third arc is 130°. The surface of the end 1, the tail end 2 and the first arc, the second arc and the third arc are provided with a 0.2-0.5mm thick anti-friction layer 3, and the anti-friction layer 3 includes carbon nanotubes and nano oxides. mixture;

[0026] In practice, as a casting mold and a detection and comparison tool, as a casting mold, the arc is selected according to the required casting arc pipe, and it will be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com