Photo-thermal power generation heat transfer and storage medium leakage detection system and method

A heat storage medium and leakage detection technology, which is applied in the direction of detecting the appearance of fluid at the leakage point, measuring devices, and material analysis through optical means, can solve problems such as leakage at installation points, avoid direct damage, and reduce failures. Links, display results intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

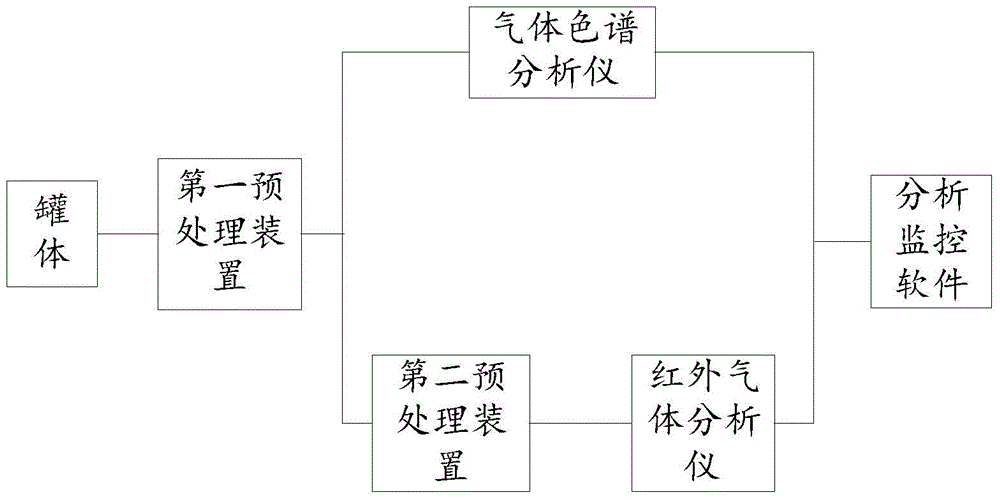

[0037] In order to improve the safety and operability of the leakage detection of the photothermal power generation heat storage heat transfer medium, the present invention proposes a photothermal power generation heat transfer heat storage medium leakage detection system, such as figure 1 As shown, the detection system includes: a tank body, a first preprocessing device, a gas chromatographic analyzer, a second preprocessing device, an infrared gas analyzer, and an analysis and monitoring module.

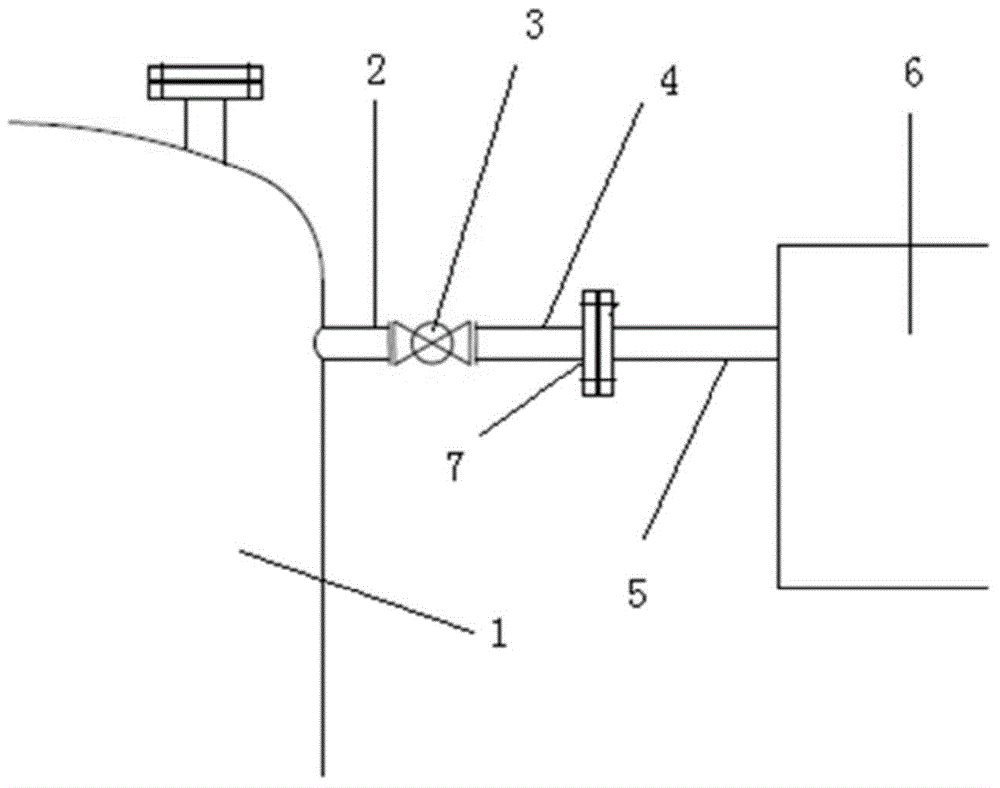

[0038] Such as figure 2 As shown, the tank body 1 is located near the exhaust port of the molten salt tank, so that it is possible to determine whether there is leakage of the heat transfer and heat storage medium by detecting the gas composition in the tank body 1 . At least one tank exhaust pipe 2 is fixed on the tank body 1, the tank exhaust pipe 2 is fixedly connected to one end of the air pressure balance valve 3, and the other end of the air pressure balance valve 3 is fixed...

Embodiment 2

[0054] Correspondingly, the present invention also provides a method for detecting leakage of photothermal power generation heat transfer heat storage medium, the method comprising the following steps:

[0055] The gas medium in the tank is obtained through the air pressure balance valve installed on the tank;

[0056] performing a first pretreatment on the gas medium, the first pretreatment including pressurization and heat preservation pretreatment;

[0057] And the gas medium after processing is divided into two paths and sent to gas chromatograph analyzer and infrared gas analyzer respectively;

[0058] Adopt gas chromatographic analyzer to detect C in the gas medium 12 content;

[0059] Carry out a second pretreatment on the gas medium sent to the infrared gas analyzer, the second pretreatment includes condensing the condensables in the gas medium, and then sending the second pretreated gas medium to the infrared gas Analyzer;

[0060] Use an infrared gas analyzer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com