Mass production method of high frequency inductors

A technology for mass production of inductors, applied in the field of inductors, can solve problems such as unfavorable inductor operation, unfavorable circuit board layout, and cumbersome problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

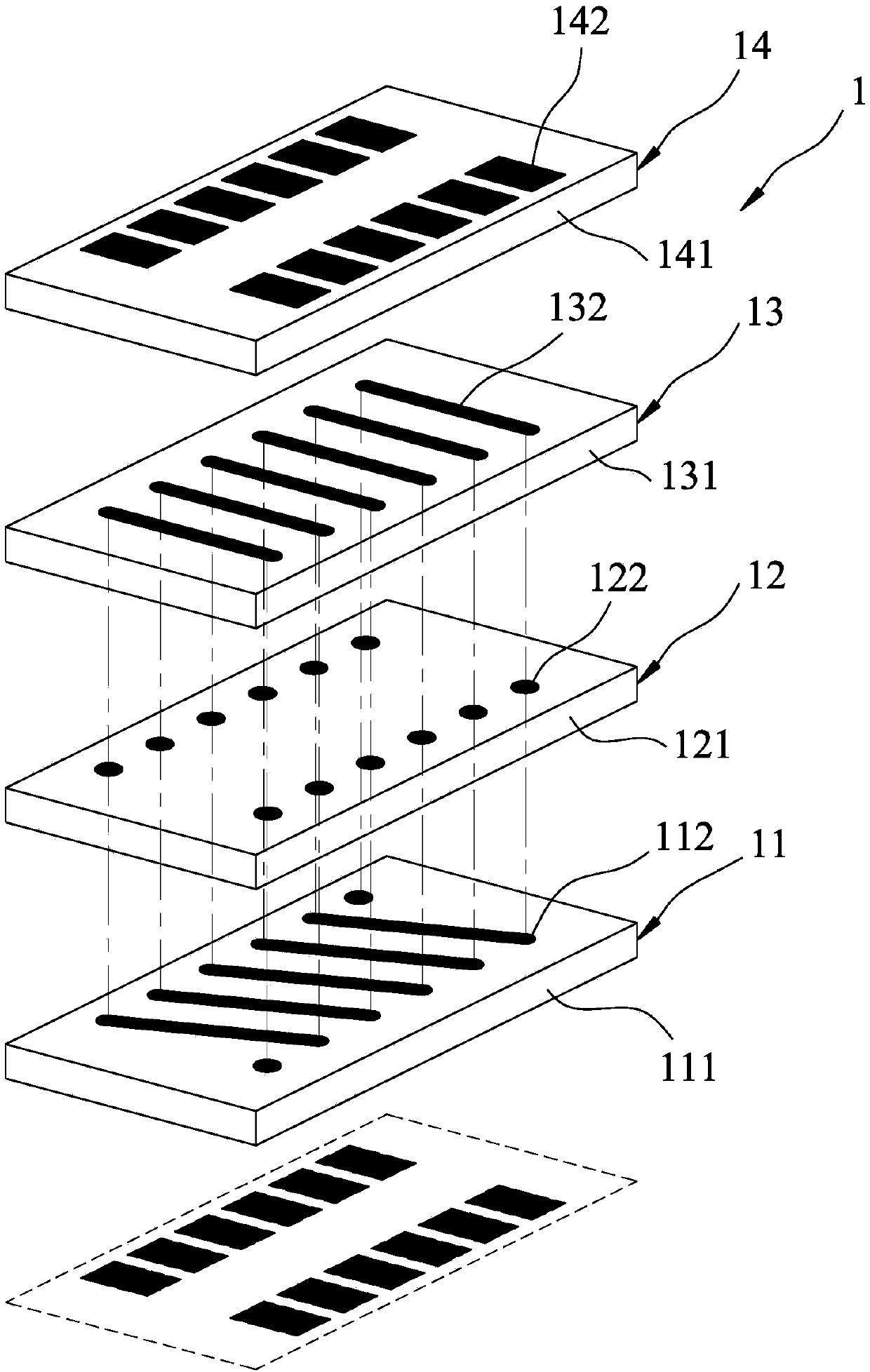

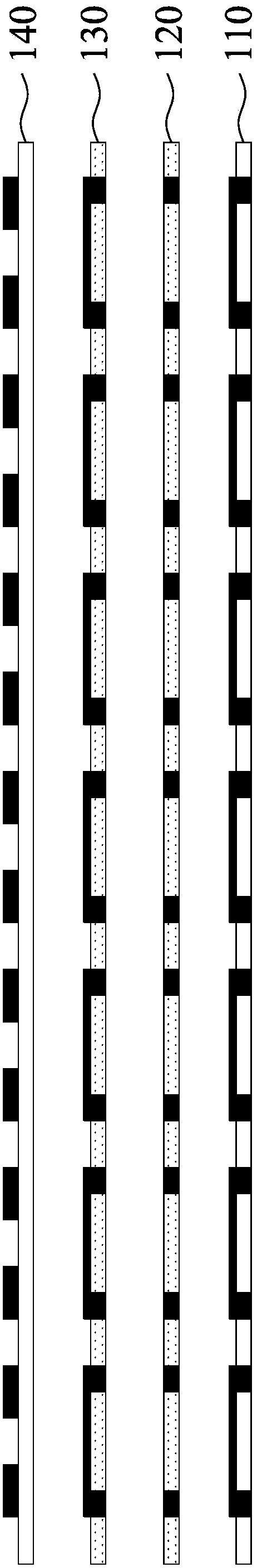

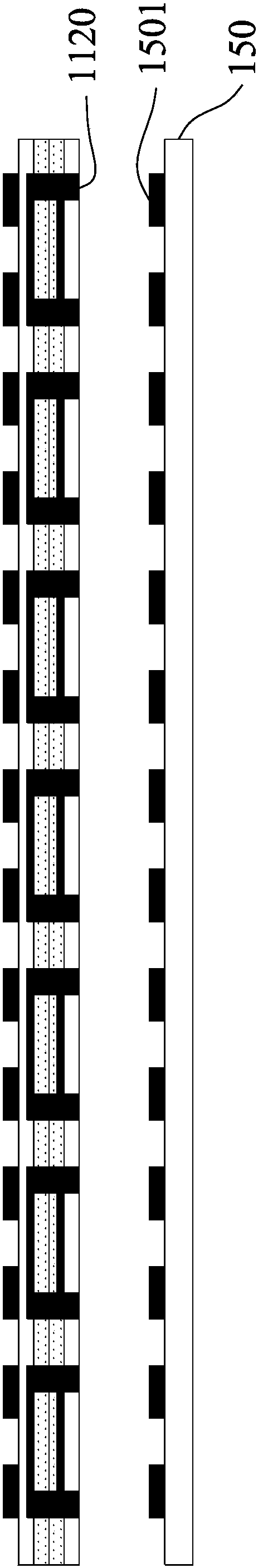

[0067] refer to Figure 8 , a first embodiment of the high frequency inductor 2 of the present invention includes a main body 21 and a first coil 23 .

[0068] The main body 21 has a contour surface 210 , and the contour surface 210 of the main body 21 includes a first side edge 211 and a second side edge 212 oppositely disposed. The main body 21 is made of a non-magnetic material and is integrated.

[0069] The first coil 23 is disposed on the main body 21 and includes a plurality of top segments 231 , a plurality of vertical segments 232 , and a plurality of bottom segments 233 . The top section 231 , the vertical section 232 and the bottom section 233 are arranged at intervals along a first direction X from the first side edge 211 toward the second side edge 212 of the main body 21 . The top section 231 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com