A low-sodium treatment process of aquatic seasoning sauce by electrodialysis

A processing technology and sauce technology, which is applied in the field of electrodialysis low-sodium treatment technology of aquatic sauce, can solve the problems of large loss of nutrient amino acids, reduction of salt content and loss, etc., so as to achieve accurate and controllable salt content and reduce loss. , the effect of reducing churn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

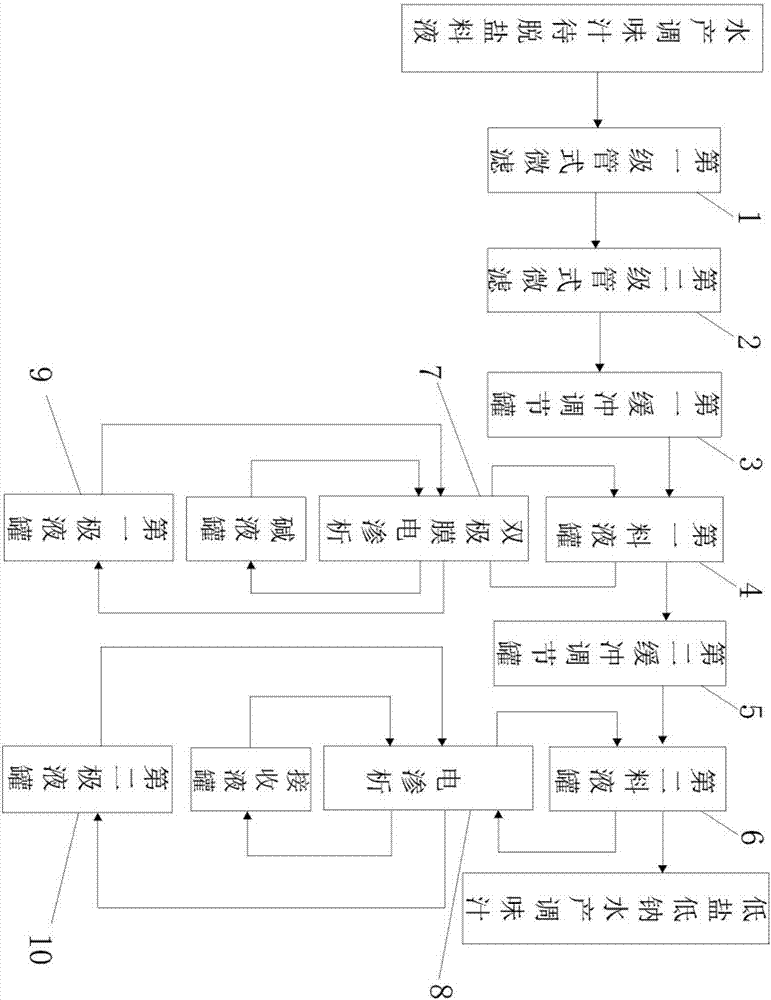

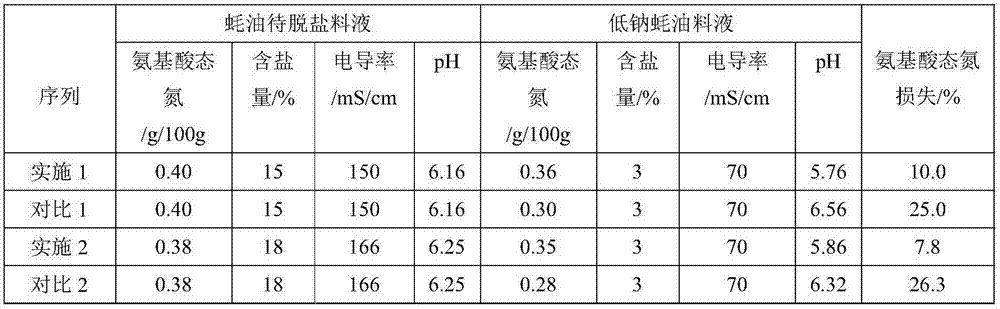

[0018] refer to figure 1 As shown, a kind of oyster sauce of aquatic seasoning is selected as an example, wherein the salt content of the feed solution to be desalted is 15%, the measured conductivity is 150mS / cm, the amino acid nitrogen content is 0.40g / 100g, and the pH is 6.16. After filtering through the first-stage tubular microfiltration device 1 (filtering precision is 5 μm) and the second-stage tubular microfiltration device 2 (filtering precision is 1 μm), suspended matter impurities, etc. are removed to obtain clarified oyster sauce liquid with SS of 4.0, which is poured into In the first buffer adjustment tank 3. The clarified oyster sauce feed liquid enters the first feed liquid tank 4, and the pH value is adjusted to the isoelectric point of the solution through the bipolar membrane electrodialysis device 7 (ED). Among them, the membrane of the bipolar membrane electrodialysis device is 100×200mm, 15 pairs of membranes, and the average current density is 250A / cm ...

Embodiment 2

[0023] refer to figure 1 As shown, a kind of oyster sauce of aquatic seasoning is used as an example, wherein the salt content of the feed liquid to be desalted is 18%, the measured conductivity is 166mS / cm, the amino acid nitrogen content is 0.38g / 100g, and the pH is 6.25. After filtering through the first-stage tubular microfiltration device (filtering precision of 5 μm) and the second-stage tubular microfiltration device (filtering precision of 1 μm), suspended solids and impurities are removed to obtain clarified oyster sauce liquid with SS of 4.0, which flows into the first buffer adjustment tank. The clarified aquatic seasoning juice enters the first feed liquid tank, and adjusts the pH value to the isoelectric point of the solution through bipolar membrane electrodialysis (ED). Among them, the membrane of bipolar membrane electrodialysis is 100×200mm, 15 pairs of membranes, and the average current density is 250A / cm 2 , Membrane pair voltage 0.2V. The lye liquid tank...

Embodiment 3

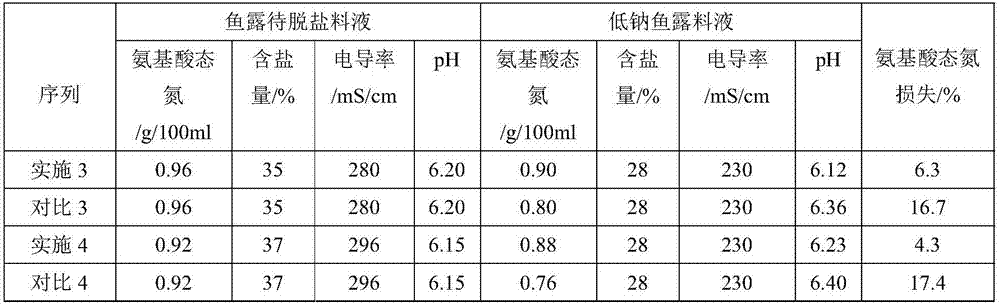

[0032] refer to figure 1 As shown, a fish sauce of aquatic seasoning is selected as an example, wherein the salt content of the feed solution to be desalted is 35%, the test conductivity is 280mS / cm, the amino acid nitrogen content is 0.96g / 100ml, and the pH is 6.20. After filtering through the first-stage tubular microfiltration device (filtering precision of 5 μm) and the second-stage tubular microfiltration device (filtering precision of 1 μm), suspended solids and impurities are removed to obtain a clarified fish sauce liquid with SS of 3.8, which is poured into the second-stage tubular microfiltration device. A buffer adjustment tank. The clarified fish sauce feed liquid enters the first feed liquid tank, and the pH value is adjusted to the isoelectric point of the solution through bipolar membrane electrodialysis (ED). Among them, the membrane of bipolar membrane electrodialysis is 100×200mm, 15 pairs of membranes, and the average current density is 300A / cm 2 , Membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com