High-temperature wear-resistant alloy guide roll of finishing mill and preparation method thereof

A technology of high-temperature wear-resistant alloy and finishing mill, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of low service life, poor high-temperature wear resistance, short service life of guide rolls, etc., and achieve high wear resistance performance, improve high temperature resistance, and protect the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

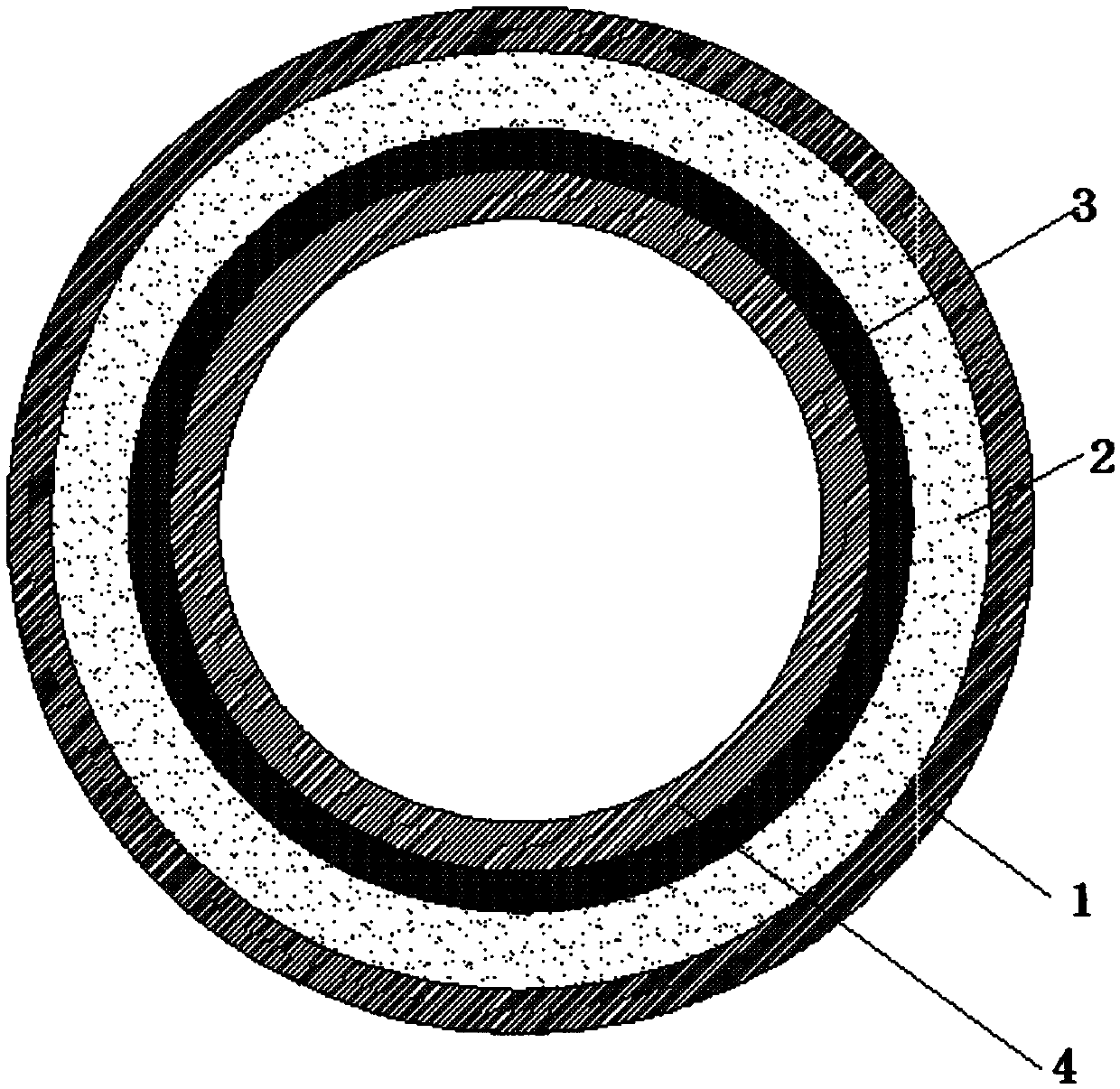

[0023] A high-temperature wear-resistant alloy guide roll for a finishing mill, comprising a first metal layer 1, a ceramic layer 2, an elastic layer 3 and a second metal layer 4;

[0024] The inner surface of the first metal layer 1 is bonded with a ceramic layer 2;

[0025] The inner surface of the ceramic layer 2 is fitted with a second metal layer 4;

[0026] Wherein, the second metal layer 4 is in clearance fit with the ceramic layer 2;

[0027] Wherein, an elastic layer 3 is arranged between the ceramic layer 2 and the second metal layer 4 .

[0028] Wherein, the first metal layer 1 contains (Cr, Fe) 7 C 3 Carbide; the second metal layer 4 is a stainless steel tube.

[0029] Wherein, the elastic layer 3 is silicone rubber; the elastic layer 3 is in interference fit with the gap formed by the ceramic layer 2 and the second metal layer 4 .

[0030] A method for preparing a high-temperature wear-resistant alloy guide roll of a finishing mill, comprising the following s...

Embodiment 2

[0038] A high-temperature wear-resistant alloy guide roll for a finishing mill, comprising a first metal layer 1, a ceramic layer 2, an elastic layer 3 and a second metal layer 4;

[0039] The inner surface of the first metal layer 1 is bonded with a ceramic layer 2;

[0040] The inner surface of the ceramic layer 2 is fitted with a second metal layer 4;

[0041] Wherein, the second metal layer 4 is in clearance fit with the ceramic layer 2;

[0042] Wherein, an elastic layer 3 is arranged between the ceramic layer 2 and the second metal layer 4 .

[0043] Wherein, the first metal layer 1 contains (Cr, Fe) 7 C 3 Carbide; the second metal layer 4 is a stainless steel tube.

[0044] Wherein, the elastic layer 3 is silicone rubber; the elastic layer 3 is in interference fit with the gap formed by the ceramic layer 2 and the second metal layer 4 .

[0045] A method for preparing a high-temperature wear-resistant alloy guide roll of a finishing mill, comprising the following s...

Embodiment 3

[0053]A high-temperature wear-resistant alloy guide roll for a finishing mill, comprising a first metal layer 1, a ceramic layer 2, an elastic layer 3 and a second metal layer 4;

[0054] The inner surface of the first metal layer 1 is bonded with a ceramic layer 2;

[0055] The inner surface of the ceramic layer 2 is fitted with a second metal layer 4;

[0056] Wherein, the second metal layer 4 is in clearance fit with the ceramic layer 2;

[0057] Wherein, an elastic layer 3 is arranged between the ceramic layer 2 and the second metal layer 4 .

[0058] Wherein, the first metal layer 1 contains (Cr, Fe) 7 C 3 Carbide; the second metal layer 4 is a stainless steel tube.

[0059] Wherein, the elastic layer 3 is silicone rubber; the elastic layer 3 is in interference fit with the gap formed by the ceramic layer 2 and the second metal layer 4 .

[0060] A method for preparing a high-temperature wear-resistant alloy guide roll of a finishing mill, comprising the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com