A kind of hydrogenated styrene diene copolymer viscosity index improver and preparation method thereof

A viscosity index improvement, diene copolymer technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve problems such as difficult control of graft ratio and functionalization degree, easy coupling and degradation, and affecting product performance. , to achieve the effect of easy control of product structure, improved soot dispersion, low probability of cross-linking and degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

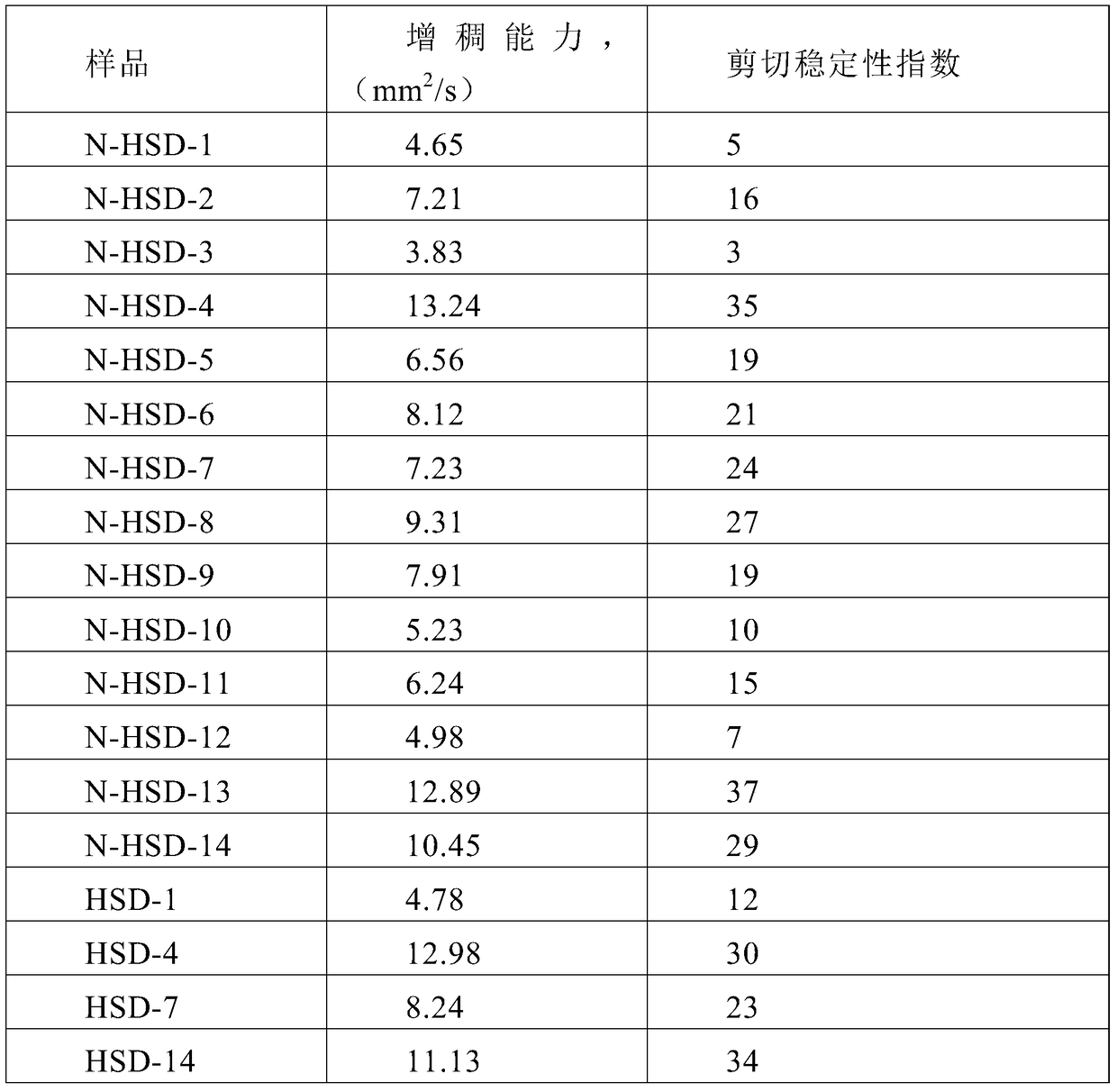

Examples

Embodiment 1

[0029]Dissolve 1.62g of butadiene in 61.0g of toluene through gasification absorption, store in the reactor, then add 18.1g of isoprene to the reactor, mix well; add diglyme and sec-butyl Lithium (the molar ratio of diethylene glycol dimethyl ether to sec-butyllithium is 1:5), the amount of sec-butyllithium added is 1.0mmol, and the reaction temperature is 70°C; when the monomer conversion rate exceeds 95% 0.4 g of styrene was added to the reactor to continue the reaction for 60 minutes, at which point the molecular weight of the polymer was 20600. Raise the temperature of the reactor to 90° C., add 3.0 mmol of divinylbenzene into the reactor at one time, and after 60 minutes of coupling reaction, add 0.1 g of 2-vinylpyridine into the reaction system for 30 minutes to react. After the reaction was completed, 1.0 mmol of isopropanol was added to the reaction system to terminate the reaction.

[0030] The above-mentioned solution is transferred in the hydrogenation reactor, and...

Embodiment 2

[0035] 3.1g of butadiene is dissolved in 180.2g of cyclohexane by gasification absorption, stored in the reactor, then 14.9g of isoprene is added to the reactor, and mixed uniformly; add tetrahydrofuran and n-butyllithium (tetrahydrofuran and The molar ratio of n-butyllithium is 5:1), the addition of n-butyllithium is 0.4mmol, and the reaction temperature is 60°C; when the monomer conversion exceeds 95%, add 2.1g styrene to the reactor to continue After 60 minutes of reaction, the molecular weight of the polymer was 49800. Add 3.0 mmol of divinylbenzene into the reactor, feed continuously, and the feeding is completed within 30 minutes. After 60 minutes of coupling reaction, 0.2 g of 4-vinylpyridine is added into the reaction system for 30 minutes to react. After the reaction was completed, 0.4 mmol of isopropanol was added to the reaction system to terminate the reaction.

[0036] The above-mentioned solution is transferred in the hydrogenation reactor, and 2-ethylhexanoic a...

Embodiment 3

[0039] Dissolve 12.0g of butadiene in 180.0g of n-hexane through gasification absorption, store in the reactor, then add 6.9g of isoprene into the reactor, mix well; add tetramethylethylenediamine and sec-butyl base lithium (the molar ratio of tetramethylethylenediamine to sec-butyllithium is 2:1), the addition of sec-butyllithium is 1.0mmol, and the reaction temperature is 50°C; when the monomer conversion rate exceeds 95%, 1.1 g of styrene was added to the reactor and the reaction was continued for 60 minutes. At this time, the molecular weight of the polymer was 19800. Add 20.0mmol of divinylbenzene into the reactor in four times, 5.0mmol each time, with an interval of 20 minutes between each addition, and then react for 60 minutes after the addition, and add 0.16g of 2-vinylpyridine into the reaction system to react 30 minutes. After the reaction was completed, 1.0 mmol of isopropanol was added to the reaction system to terminate the reaction.

[0040] The above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com