Preparation method of nitrate plasticized polyether propellant pure sol

A plasticized polyether and propellant technology, which is applied in the field of separation of energetic polymer materials, can solve the problems that have not been reported in the literature, and achieve the effects of simple and easy preparation methods, reduced sample processing risks, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Purification and preparation of nitrate ester plasticized polyether propellant pure sol

[0022] Step 1: Prepare the propellant sample and soak it in a solvent: choose petroleum ether as the solvent, soak it for 2 days, change the solvent 6 times during this period, and wash it with a small amount of solvent several times until the solution is colorless.

[0023] Step 2, using a Soxhlet extractor to extract the sol. Heating and reflux at 85°C for 2 days, using chloroform as the solvent, collecting the solution, and recovering the solvent to obtain a coarse sol.

[0024] Step 3, preparing pure sol. The crude sol was put into a dialysis bag with a cut-off molecular weight of 500-1000, dialyzed with tap water for 3 days, and then dialyzed with 10% ethanol aqueous solution for 4 days, taken out and freeze-dried to obtain pure sol.

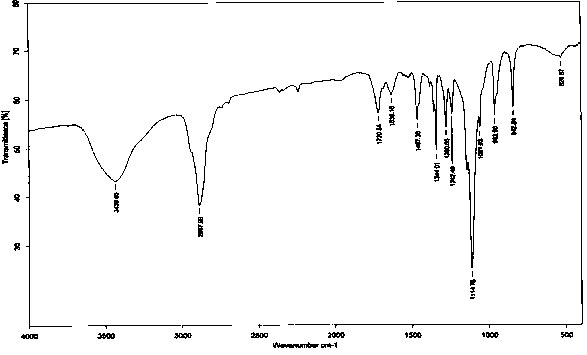

[0025] figure 1 It is the infrared spectrogram of the pure sol obtained in Example 1. It can be seen in the figure that the so...

Embodiment 2

[0026] Embodiment 2: Purification and preparation of nitrate ester plasticized polyether propellant pure sol

[0027] Step 1, preparing propellant samples and soaking in a solvent: choose methanol as the solvent, soak for 2 days, change the solvent 10 times during the period, and wash with a small amount of solvent for several times until the solution is colorless.

[0028] Step 2, using a Soxhlet extractor to extract the sol. Acetone was selected as the solvent, heated and refluxed at 70°C for 1 day, the solution was recovered, and the solvent was volatilized to obtain a crude sol.

[0029] Step 3, preparing pure sol. The crude sol was put into a dialysis bag with a cut-off molecular weight of 2000. After dialysis with tap water for 4 days and 30% ethanol aqueous solution for 3 days, the sol was taken out and freeze-dried to obtain pure sol.

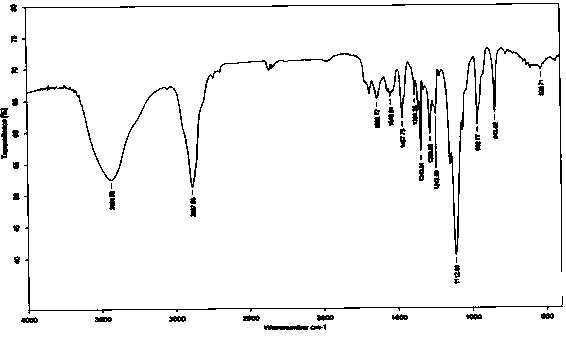

[0030] The infrared spectrum of the pure sol is shown in figure 2 , it can be seen in the figure that the sol is polyether polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com