Method for Junction Staining of Transmission Electron Microscopy Samples

An electron microscope and sample technology, applied in the preparation of test samples, etc., can solve problems such as analysis failures, achieve the effects of improving accuracy and success rate, improving observation quality, and strengthening material contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0026] Figure 1 to Figure 15 Each step of the method for staining a transmission electron microscope sample junction according to a preferred embodiment of the present invention is schematically shown.

[0027] like Figure 1 to Figure 15 Shown, according to the method for transmission electron microscope sample junction staining of preferred embodiment of the present invention comprises:

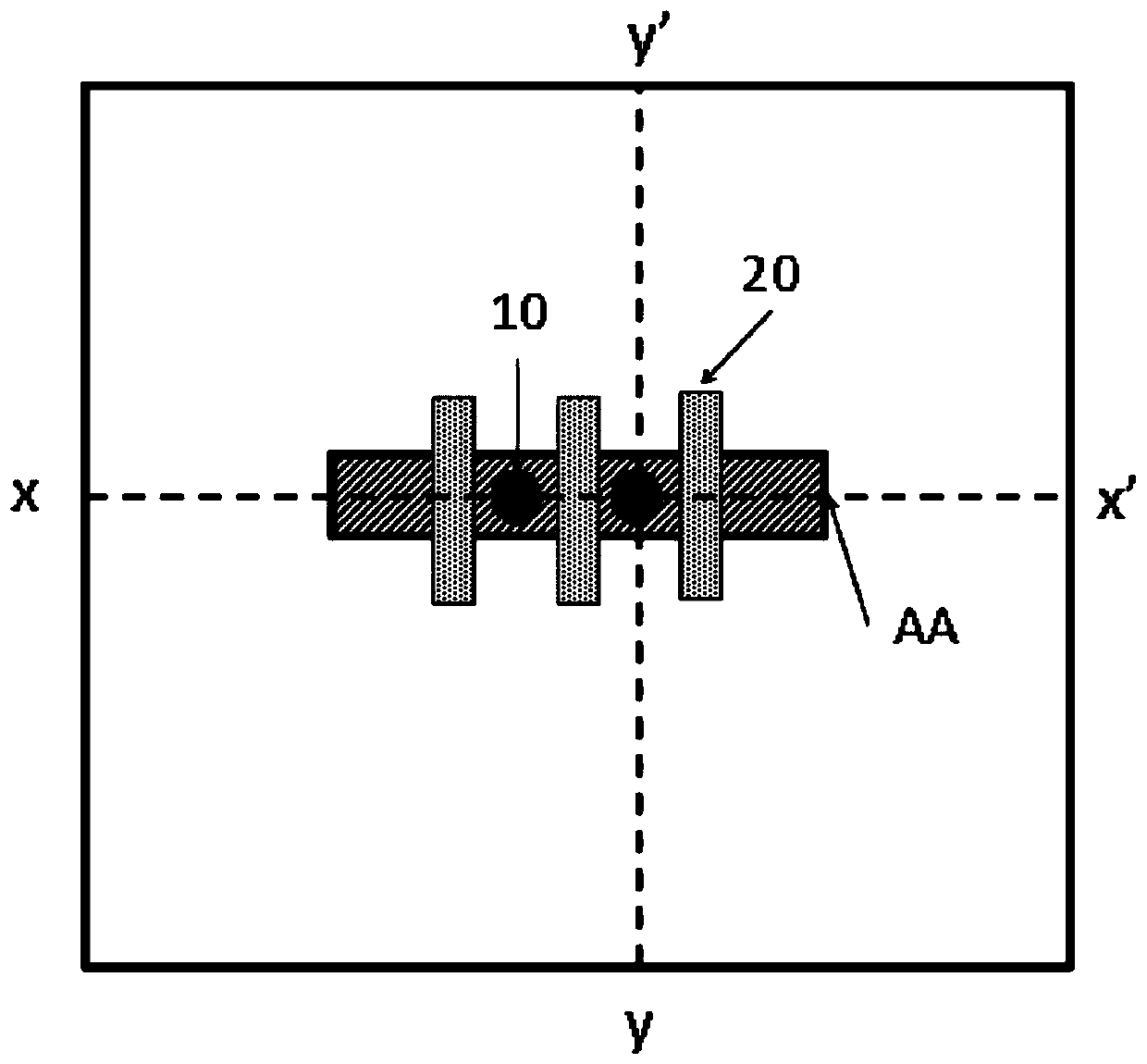

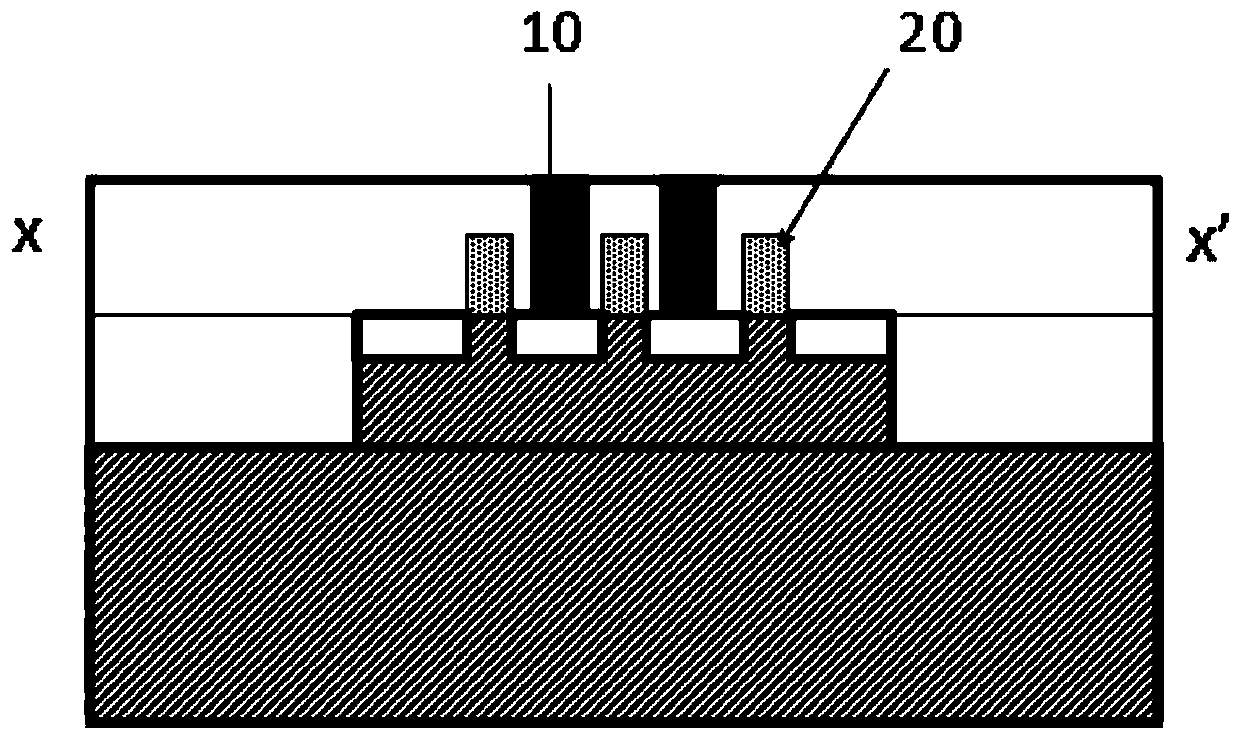

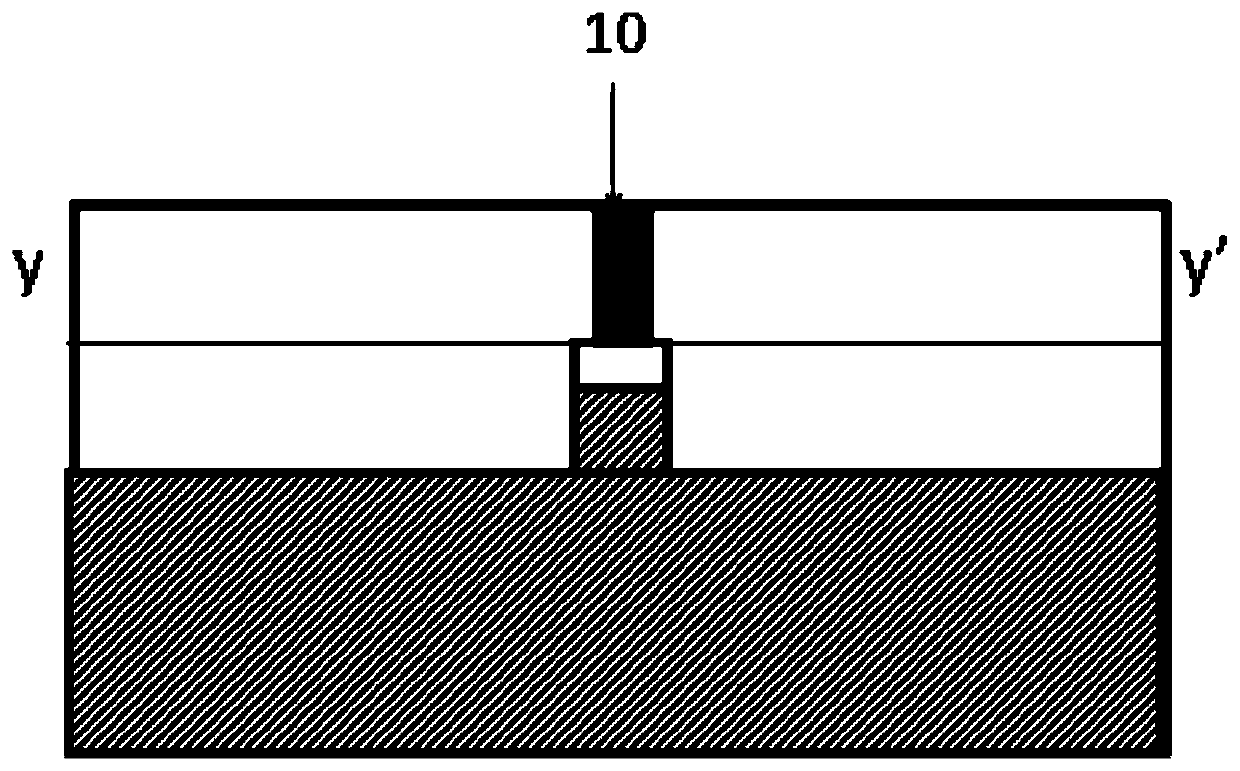

[0028] The first step: processing the chip sample to expose the contact hole 10; for example, polysilicon 20 near the contact hole 10;

[0029] The resulting structure is as figure 1 top view of figure 2 shown along the figure 1 The cross-sectional view taken by the dotted line X-X', and image 3 shown along the figure 1 Shown in the cross-sectional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com