Magnetic-suspending rotary drumfluid damp measuring apparatus

A fluid damping and magnetic levitation technology, which is applied in measuring devices, instruments, flow characteristics, etc., can solve problems such as the reduction of measurement accuracy, and achieve the effect of improving measurement accuracy and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

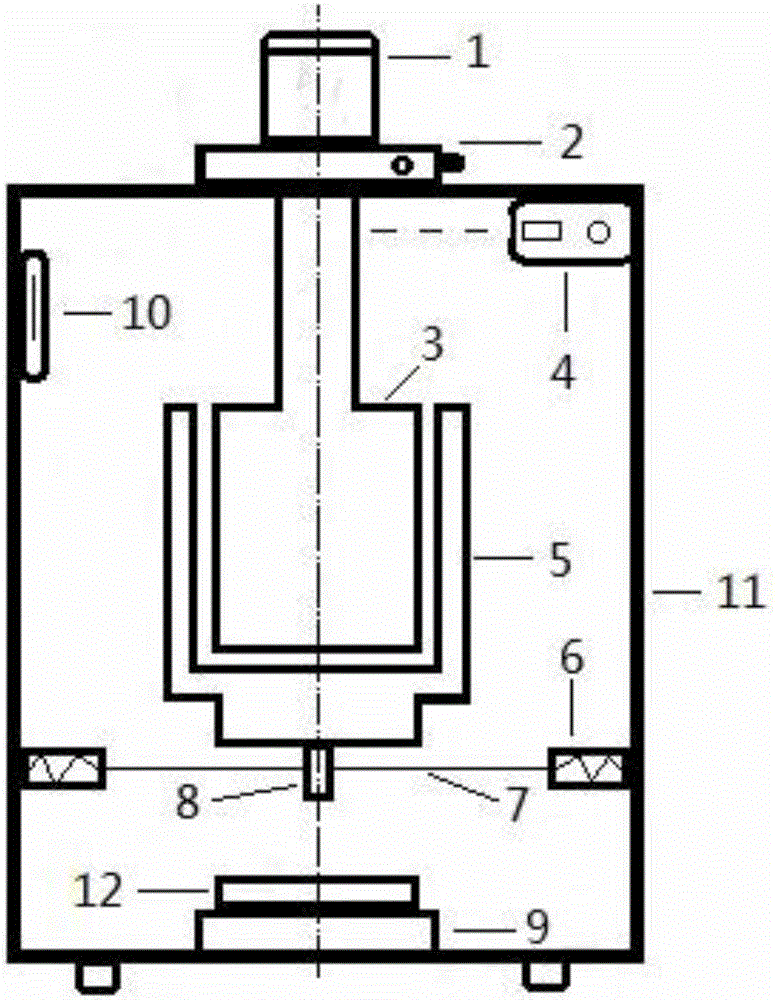

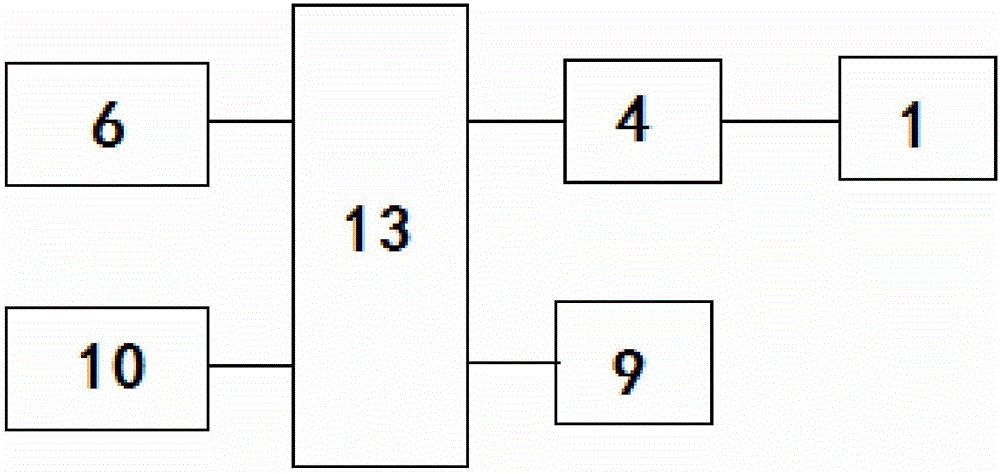

[0034] In this example, see figure 1 and figure 2 , a fluid damping measuring instrument for a magnetic levitation drum, comprising a sealed case 11, a rotating system, a main controller 13, a magnetic levitation actuator and a fluid measuring device, specifically:

[0035]The fluid to be tested is injected into the sealed case 11; the rotation system is composed of a motor 1, a two-dimensional translation support 2 and a cylinder 3, the cylinder 3 has a set diameter, and the motor 1 and the two-dimensional translation support 2 are installed outside the sealed case 11. The drive shaft of the motor 1 is set vertically, the cylinder 3 is set in the sealed case 11 and immersed in the fluid to be tested, the drive shaft of the motor 1 coaxially drives the cylinder 3, so that the motor 1 drives the cylinder 3 to rotate synchronously; the magnetic levitation actuator Including a magnetic levitation drum 5, a magnetic field controller 9 and a tray 12, the magnetic levitation drum ...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

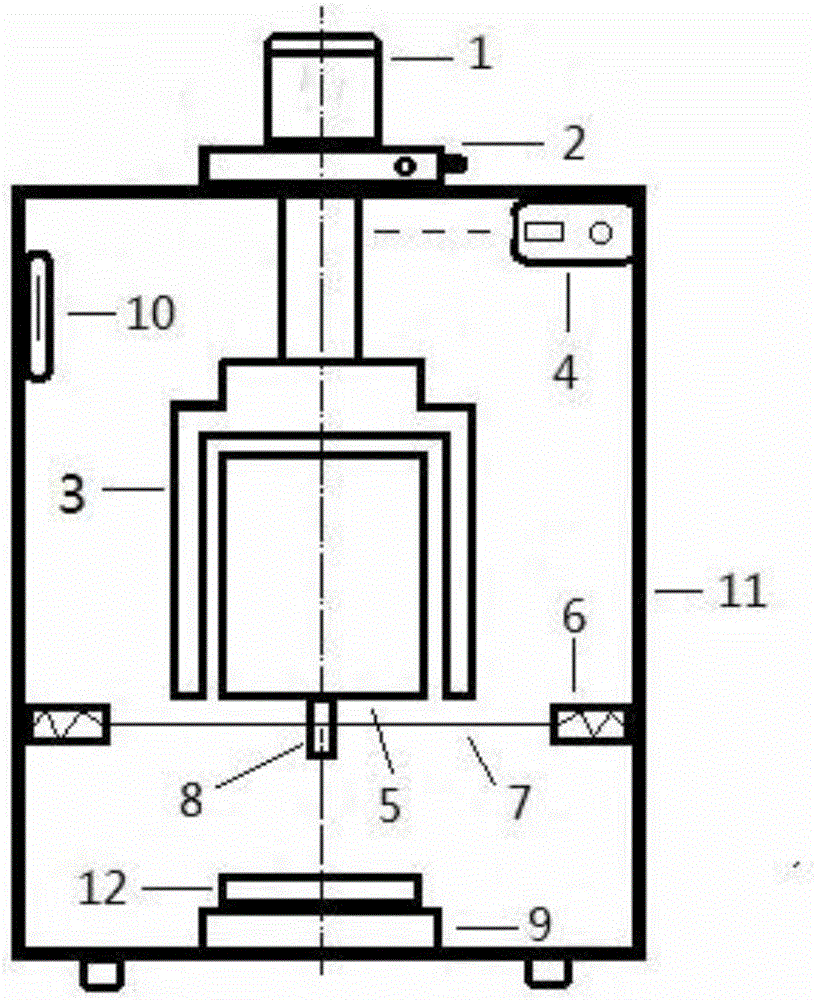

[0041] In this example, see image 3 , the cylinder 3 is a hollow cylindrical device with an open bottom, the magnetic levitation drum 5 is a cylindrical structure, the magnetic levitation drum 5 is inserted into the cylinder 3 from the bottom direction, and is coaxial with the cylinder 3 to form a suit with an intermediate fluid layer In the shaft force transmission device, the inner diameter of the hollow cavity of the cylinder 3 and the outer diameter of the magnetic levitation drum 5 have set dimensions. In this embodiment, the motor 1 drives the magnetic levitation drum 5 to rotate, and the magnetic levitation drum 5 is in the magnetic levitation state. The rotating cylinder 3 drives the fluid to rotate, and the rotating fluid drives the magnetic levitation drum 5 to rotate. Shaft, tension wire 7 measures the torque of magnetic levitation drum 5 or thin rod 8. The motor 1 drives the cyli...

Embodiment 3

[0043] This embodiment is basically the same as the previous embodiment, and the special features are:

[0044] In this example, see Figure 4 , the rotation system adopts the bottom transmission method, the motor 1 and the two-dimensional translation support 2 are installed at the bottom of the sealed cabinet 11, and the cylinder 3 located above is driven from below to rotate; the magnetic levitation actuator adopts the magnetic levitation suction force supply method, and the magnetic field controller 9 is installed On the top of the magnetic levitation drum 5, the magnetic levitation drum 5 is subjected to an upward magnetic levitation suction force from above through the magnetic field controller 9, so that the magnetic levitation drum 5 is suspended in the fluid to be tested.

[0045] In this example, see Figure 4 , the magnetic levitation drum 5 is a hollow cylindrical device with an open bottom, and the cylinder 3 is inserted into the magnetic levitation drum 5 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com