Method for measuring oxygen effective diffusion coefficient in fuel cell catalyst layer

A fuel cell and diffusion coefficient technology, applied in gas diffusion analysis, diffusion analysis, measuring devices, etc., can solve problems such as difficult reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

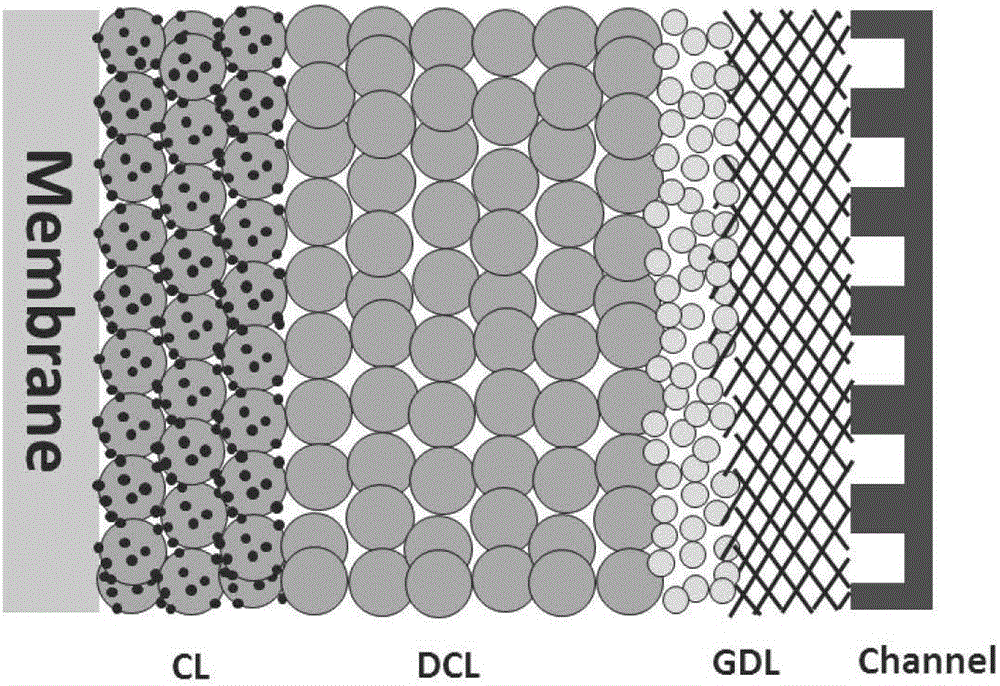

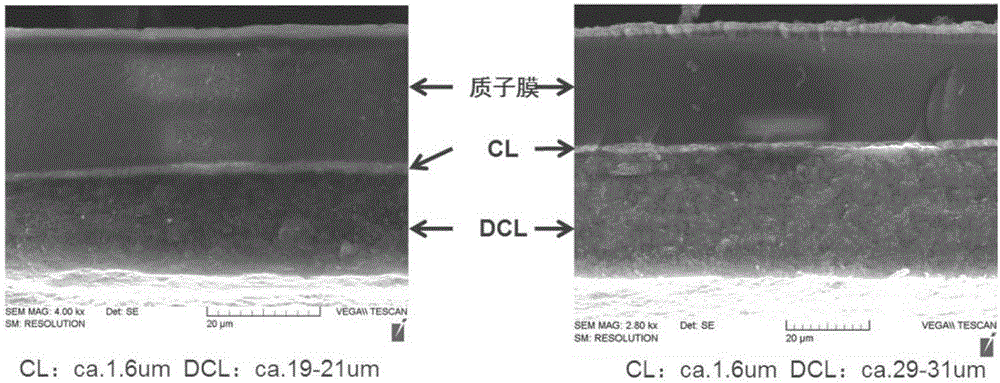

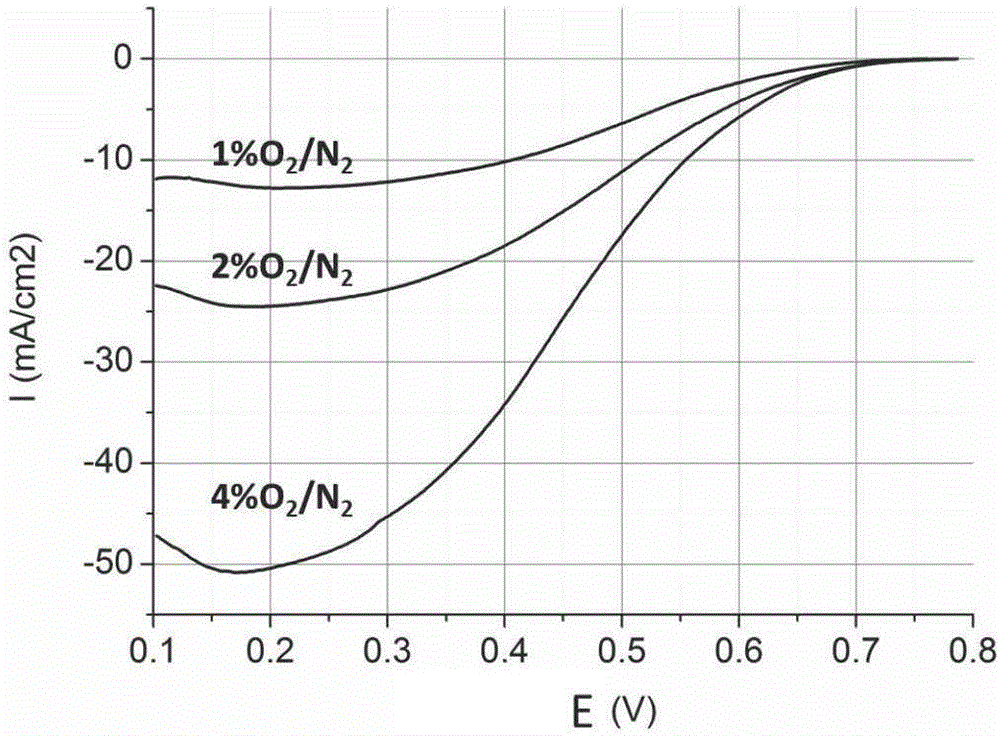

[0032] In the present invention, the membrane electrode required for the experiment is prepared by electrostatic spraying method, and the structure is as follows: figure 1 shown. Firstly, the Pt / C catalyst slurry was prepared, the ion resin was commercial Nafion, and the solvent was ethanol. The mass fraction of carbon in the slurry is 0.39%, and the mass ratio of Nafion to carbon is 0.8. The prepared slurry was ultrasonically vibrated for 20 minutes and then used for spraying. In this example, the cathode and anode catalytic layers are sprayed on both sides of the Nafion proton membrane by electrostatic spraying method, the spraying temperature is 90°C, and the Pt loading of the cathode and anode is 0.1mg / cm 2 . Second, spray DCL with different thicknesses on the outside of the sprayed cathode catalyst layer. The DCL thicknesses selected in this example are 15um, 22um, and 30um. The thickness of the DCL was measured by electron microscopy (e.g. figure 2 shown). The ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com