Local Positioning Structure for Reactor Electric Heating Simulation Rod Bundle

A technology of electric heating rods and positioning structures, applied in reactors, reactor fuel elements, nuclear power generation, etc., can solve problems such as unfavorable light rod experimental characteristics, obvious influence of flow field, and difficult processing, and achieve low production technology difficulty and improved Structural stability, the effect of reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

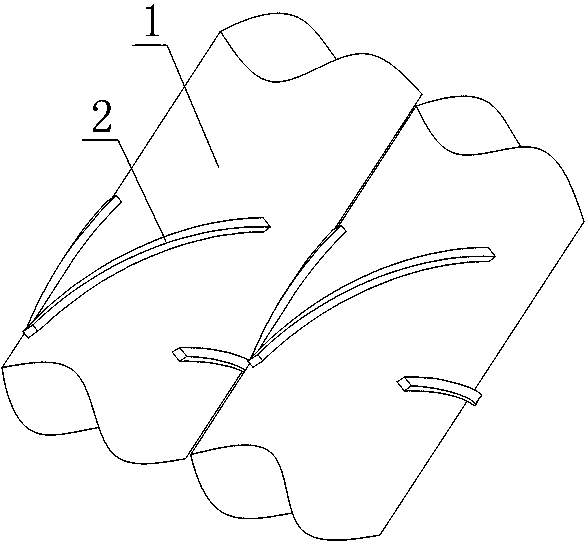

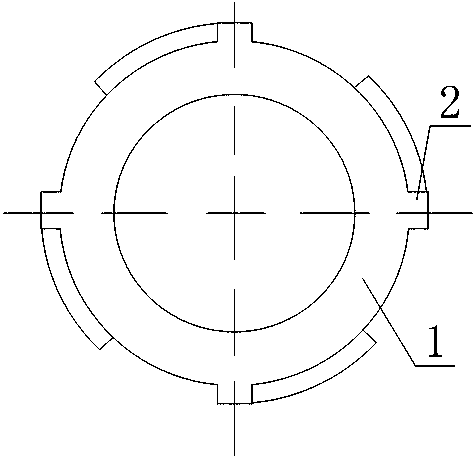

[0024] Such as figure 1 , figure 2 As shown, the local positioning structure for the reactor electric heating simulation rod bundle includes several electric heating rods 1 arranged parallel to each other, and several winding ribs 2 are arranged on the outer walls of the electric heating rods 1, and the winding ribs 2 It is fixed with the electric heating rod 1 as an integral structure, and the material of each electric heating rod 1 is the same as that of the rib 2 wound on the electric heating rod 1 . The partial winding rib is designed as a helical winding structure of a certain size, which can be completely integrated with the electric heating rod to increase the firmness and reliability of positioning. It has the same material as the electric heating rod, which avoids structural stress caused by heterogeneous materials due to differences in thermal expansion properties, and ensures stable function during the experiment cycle. According to the geometric dimensions of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com