Double glass module eva and glass bonding performance testing method

A technology of double-glass components and detection methods, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor devices, etc., can solve the problems of component electrical performance safety, component stratification, affecting service life, etc. , Reduce the risk of use, and improve the effect of testing data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

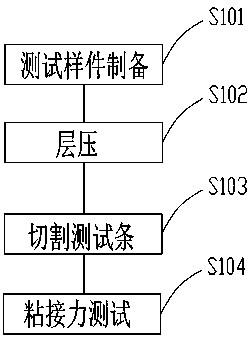

[0027] Such as figure 2 As shown, the embodiment of the present invention discloses a double-glass component EVA and glass bonding performance detection method, the method includes the following steps:

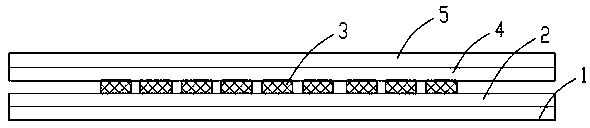

[0028] S101: Place the lower glass on a flat surface, arrange four pieces of Teflon high-temperature cloth at the four corners of the lower glass, and add a piece of Teflon high-temperature cloth between the two corners of the long side of the lower glass High-temperature cloth; then cover the lower layer of EVA, battery strings, upper layer of EVA, back plate and upper glass in turn, the number and position of the back plate correspond to the Teflon high-temperature cloth, and the battery string is located without Teflon high-temperature cloth. Cloth, preferably, the Teflon high temperature cloth is a square with a side length of 30cm, the distance between the Teflon high temperature cloth at the four corners of the lower glass is 20cm from the short side of the lower glass,...

Embodiment 2

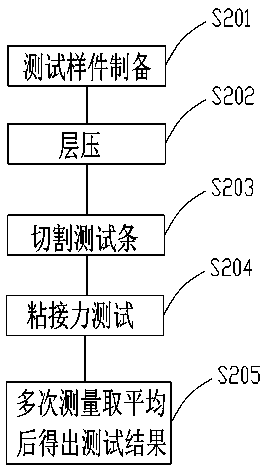

[0033] Such as image 3 As shown, the embodiment of the present invention discloses a double-glass component EVA and glass bonding performance detection method, the method includes the following steps:

[0034] S201: Place the lower glass on a plane, arrange four pieces of Teflon high-temperature cloth at the four corners of the lower glass, and add a piece of Teflon high-temperature cloth between the two corners of the long side of the lower glass High-temperature cloth; then cover the lower layer of EVA, battery strings, upper layer of EVA, back plate and upper glass in turn, the number and position of the back plate correspond to the Teflon high-temperature cloth, and the battery string is located without Teflon high-temperature cloth. Cloth, preferably, the Teflon high temperature cloth is a square with a side length of 30cm, the distance between the Teflon high temperature cloth at the four corners of the lower glass is 20cm from the short side of the lower glass, and the...

Embodiment 3

[0040] Such as Figure 4 As shown, the embodiment of the present invention discloses a double-glass component EVA and glass bonding performance detection method, the method includes the following steps:

[0041] S301: Material preparation: Prepare the upper and lower glass, Teflon high-temperature cloth, upper and lower EVA, back plate and battery string of the double-glass module, and make several pieces of Teflon high-temperature cloth into a 30*30cm square shape;

[0042] 2) Preliminary sample preparation: place the lower glass on a flat surface, cover the lower EVA, arrange the first piece of Teflon high-temperature cloth at a position 20cm from the short side edge of the glass and 10cm from the long side edge, and place the third piece in the same way. The Teflon high-temperature cloth at positions 4 and 6, and the Teflon high-temperature cloth at positions 2 and 5 are arranged in the middle of the long side, 10cm away from the edge of the long side. After the Teflon hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com