PtSi infrared detector for improving quantum efficiency

An infrared detector and quantum efficiency technology, applied in the field of infrared imaging, can solve the problems of low thermal sensitivity and achieve the effects of increasing transmission efficiency, reducing reflection loss, and increasing optical absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

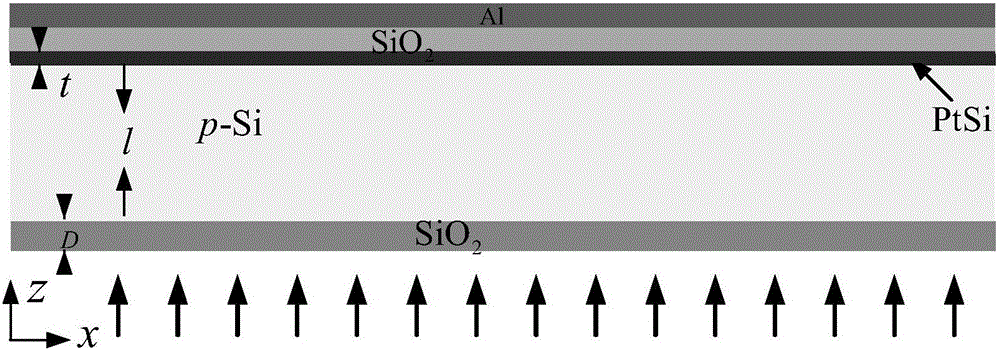

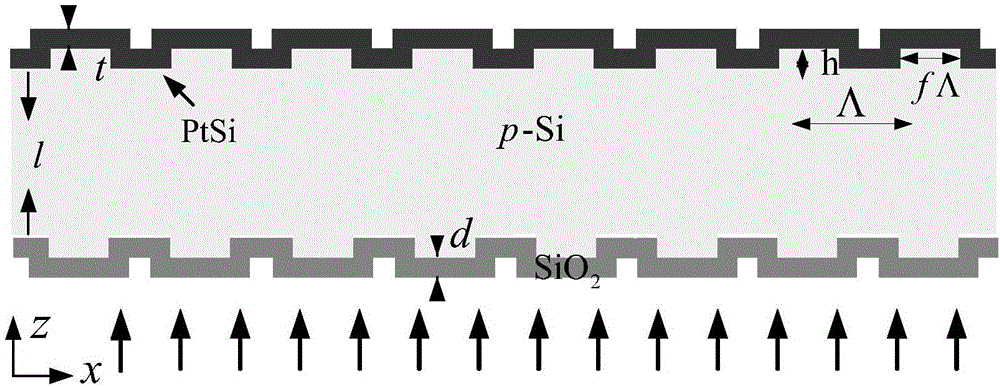

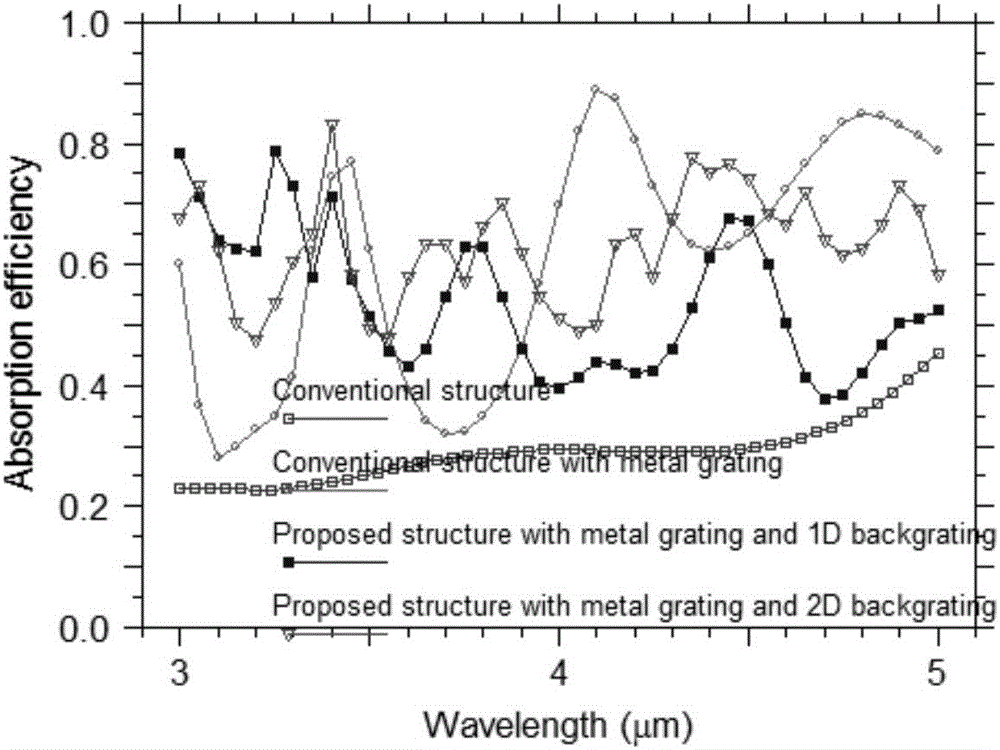

[0029] According to the basic idea above, taking the subwavelength grating anti-reflection structure and metal grating excited PtSi infrared detector as an example, by optimizing the parameters of the subwavelength grating anti-reflection structure and the parameters of the grating-type PtSi metal film, the 3μm- The reflection of the entire band at 5 μm is the smallest, and the PtSi layer absorbs the largest. After a lot of simulations, the grating period Λ, groove depth h, duty cycle f and SiO 2 Anti-reflection film thickness d, basic optimal values of grating period, groove depth, and duty cycle in grating-type PtSi metal film, and then take these optimized values, and then perform local optimization on each of these parameters. Finally, the numerical simulation shows that the period of the sub-wavelength grating anti-reflection structure is 3 μm, the grating groove depth h=0.5 μm, the grating duty cycle f=0.5, SiO 2 Anti-reflection film thickness d=0.4μm, in the grating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grating period | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com