Numerical control two-roll rolling machine provided with two flexible rolls

A double-flexible, roll-to-roll technology, applied in the direction of rolling out equipment, can solve problems such as failure to meet requirements, contact scratches, etc., achieve good internal and external surface quality, compact structure, and improve flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

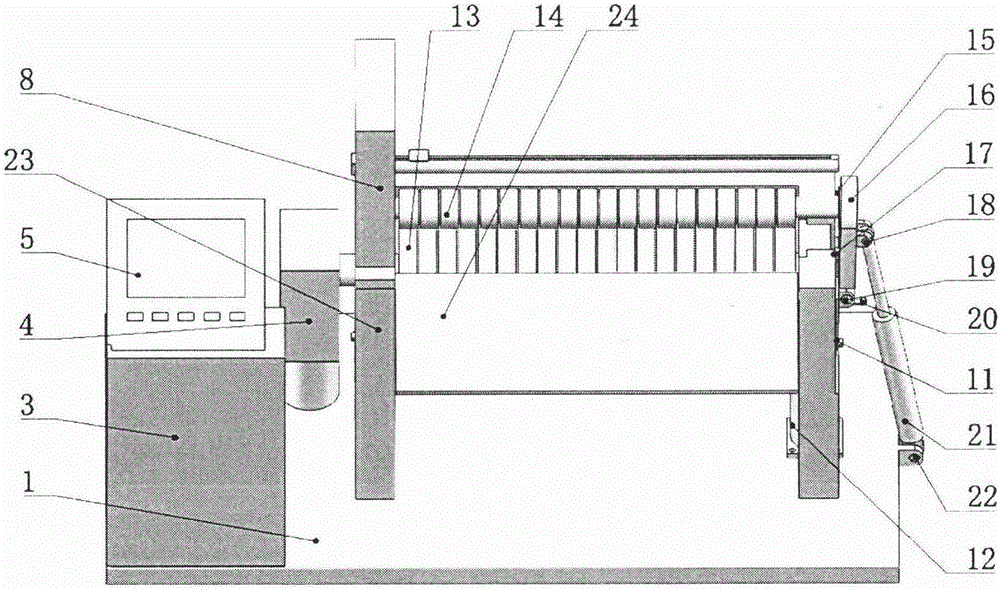

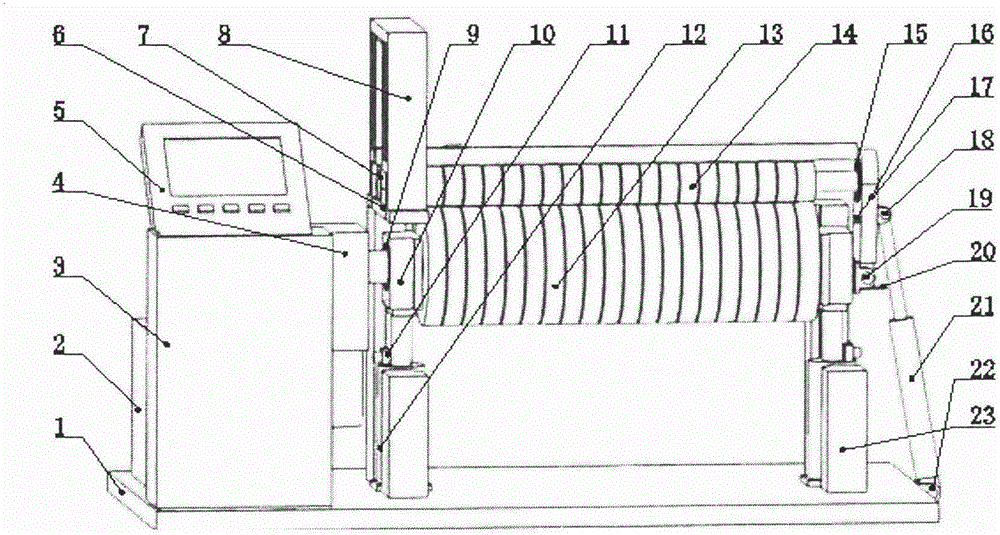

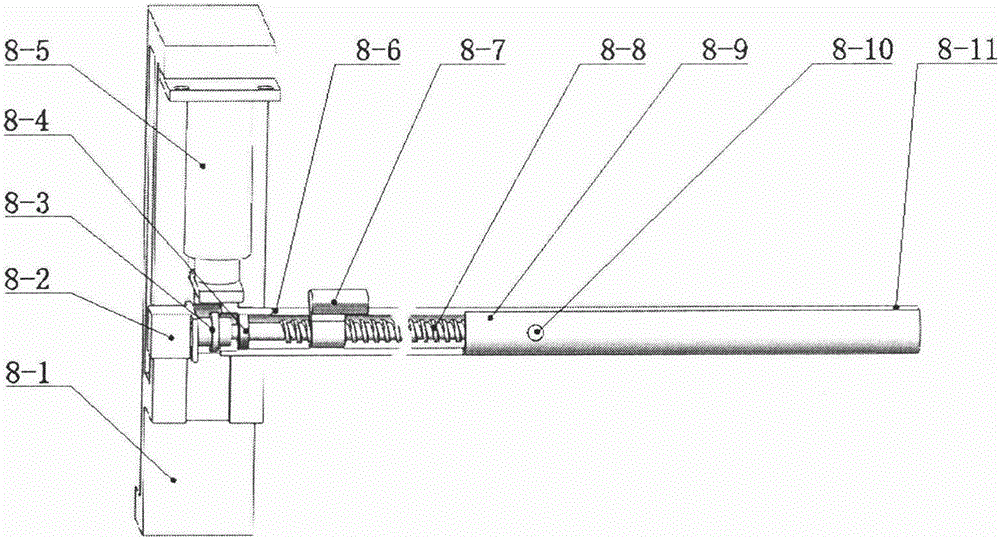

[0014] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0015] like figure 2 As shown, the double-flexible-roller CNC two-roller plate bending machine consists of a machine base (1), a hydraulic station (2), a PLC control cabinet (3), a geared motor (4), a CNC console (5), and an upper roll bearing seat (6), upper roller bearing (7), unloading device (8), lower roller bearing (9), lower roller bearing housing (10), pull rope displacement sensor (11), lower roller lifting hydraulic cylinder 12, lower rubber Roller (13), upper rubber roller (14), self-aligning bearing (15), overturn frame (16), position switch (17), pin shaft (18), pin shaft (19), position switch (20), Overturn hydraulic cylinder (21), bearing pin (22), frame (23), material table (24) (as figure 1 shown) composition. The hydraulic station (2), PLC control cabinet (3), numerical control console (5) and frame (23) are installed on the base (1), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com