W-axis rotating mechanism and manipulator capable of rotating around z-axis

A technology of rotating mechanism and manipulator, which is applied in the direction of manipulator, program control manipulator, stacking of objects, etc. It can solve the problems of potential safety hazards, inability to stop the manipulator, inconvenient use, etc., and achieve increased flexibility, simple structure and accurate assurance degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

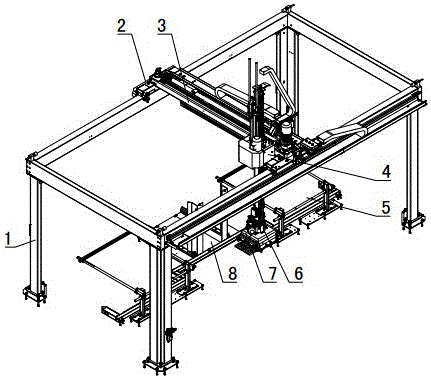

[0043] Figure 1~14 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~14 The present invention will be further described.

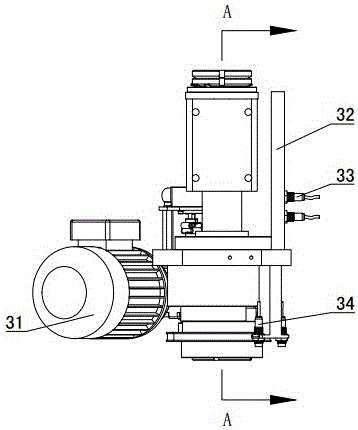

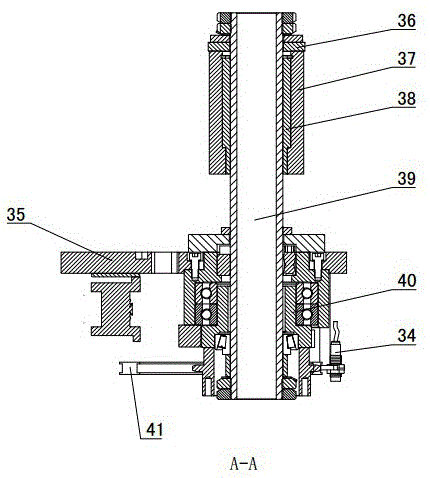

[0044] A w-axis rotation mechanism, comprising a w-axis column 39, a rotation unit rotatably mounted on the w-axis column 39, and a w-axis power unit, the w-axis power unit is fixedly connected to the w-axis column 39, and the w-axis power unit is connected to the rotation unit , and drives the rotation unit to rotate, the rotation unit is coaxially arranged with the w-axis column 39; it also includes a detection unit for measuring and limiting the angle of rotation of the rotation unit. The w-axis rotation mechanism 6 can output power in the form of rotation around the w-axis column 39, which increases the movement form of the manipulator around the z-axis and increases the flexibility of the manipulator. The picked tiles are rotated, thereby changing the posture of the tiles, and can be stacked according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com