Processing method and boring and fine grinding device for bamboo chips for piece-to-piece jointed mat and application thereof

A processing method and technology of bamboo chips, which can be used in grinding/polishing safety devices, sugarcane machining, metal processing equipment, etc., and can solve problems such as soil compaction, environmental pollution, and heavy pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

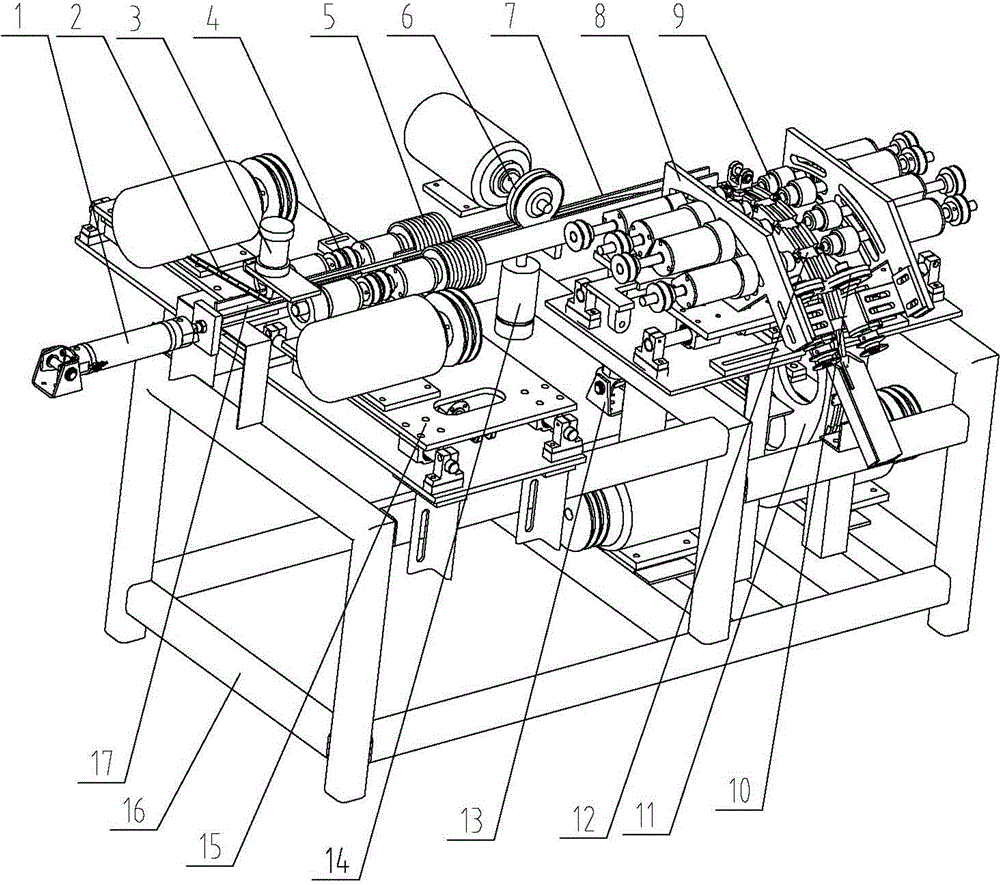

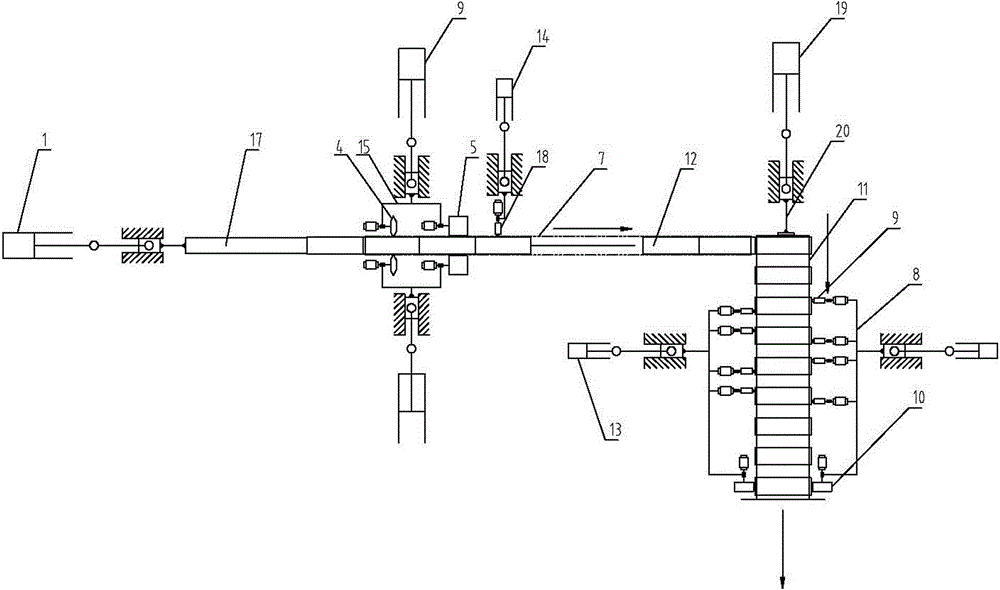

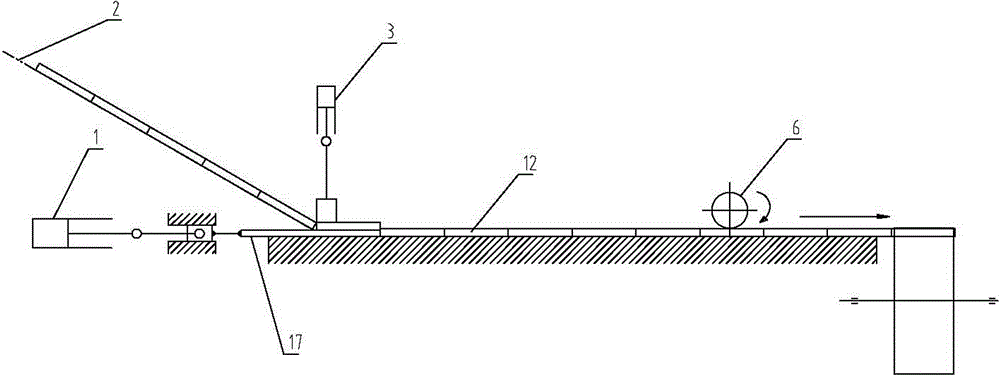

[0024] Depend on figure 1 , figure 2 , image 3 As can be seen, a kind of processing method of mahjong mat bamboo chips, it comprises the following steps:

[0025] (1) sawing the fixed-length bamboo tube into bamboo strips of required width, meanwhile, initially polishing the green and yellow sides of the bamboo strips, and then sawing the bamboo strips into bamboo strips 12 of required length;

[0026] (2) The bamboo chip 12 that step (1) is made carries out drilling fine grinding on the drilling fine grinding device, promptly finishes the milling of both sides in the length direction of the bamboo chip, the drilling in the length direction and the green surface and length of the bamboo chip, Grinding and polishing of the sides in the width direction;

[0027] Drilling fine grinding device of the present invention comprises frame 16, and frame 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com