Polylactic acid blank forging and pressing strengthening equipment

A technology of polylactic acid and equipment, which is applied in the field of forging strengthening equipment of polylactic acid, can solve the problems of high technical and equipment requirements, and achieve the effect of low requirements for equipment and low requirements for processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0030] The invention provides a polylactic acid material forging strengthening equipment for bone screws used in internal fixation devices for fractures. The requirements for the equipment are not high, and the material does not need to withstand high temperature for a long time, and the loss of molecular weight is small.

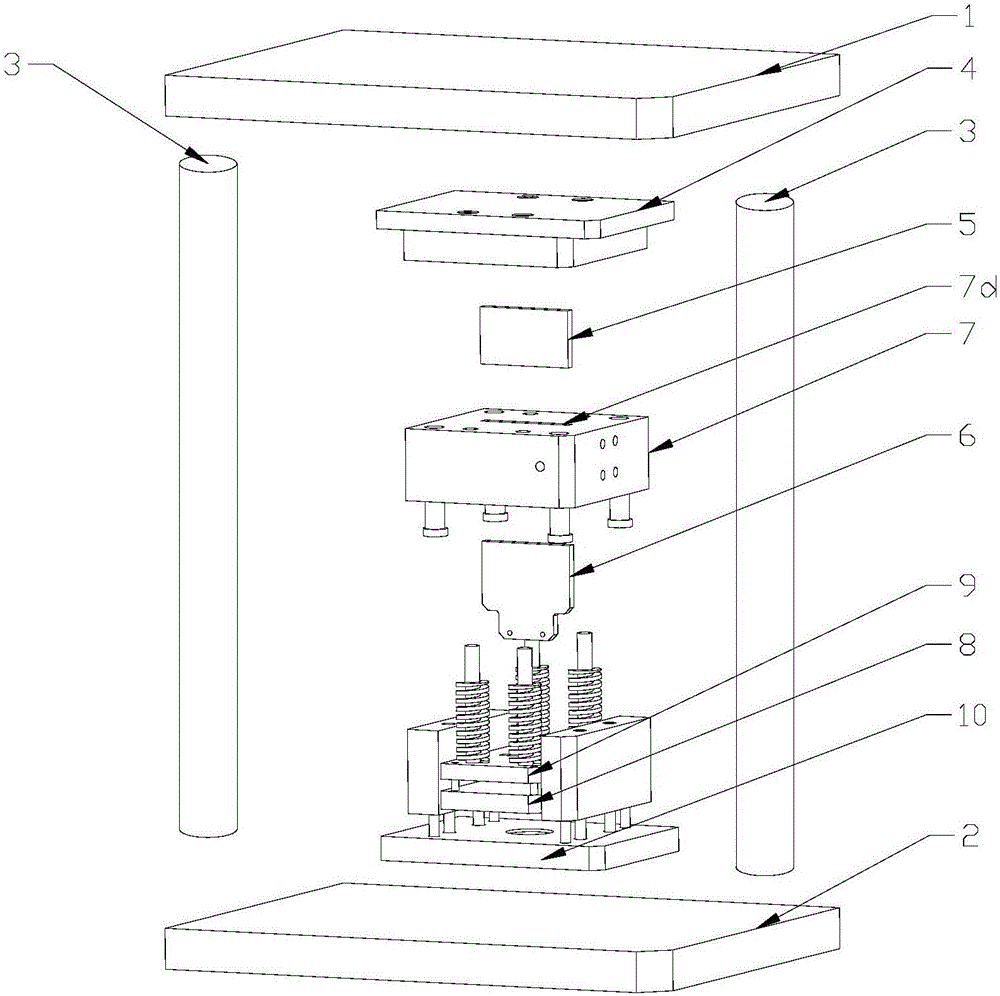

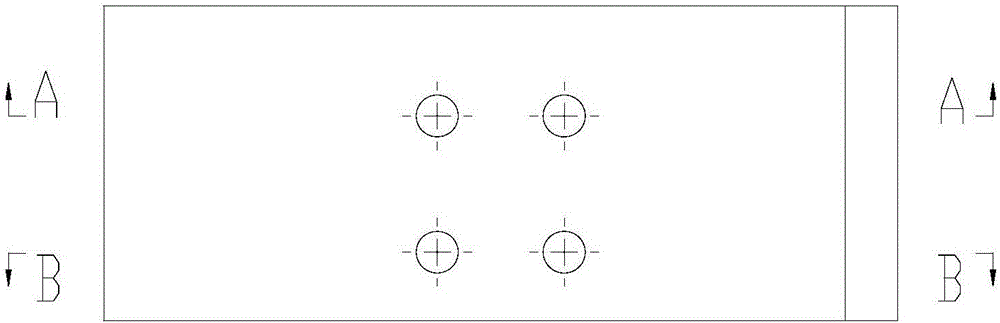

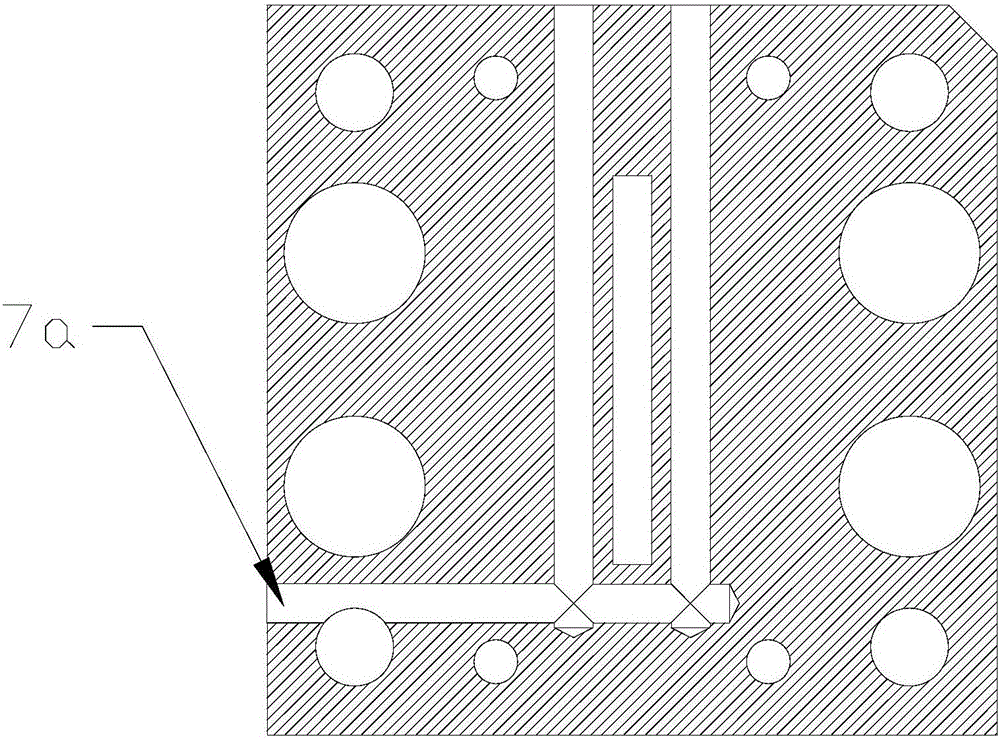

[0031] Such as figure 1 As shown, the present invention discloses a polylactic acid blank material forging strengthening equipment, which includes an equipment movable plate 1 and an equipment workbench 2, the equipment movable plate 1 is fixed above the equipment workbench through the equipment guide column 3, and the bottom of the equipment movable plate 1 A briquetting block 5 is provided, and the briquetting block is fixed on the bottom of the movable plate 1 of the equipment through the front formwork 4; a bottom plate 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com