Automobile anti-collision beam and manufacturing method thereof

A technology of anti-collision beams and automobiles, which is applied to vehicle parts, vehicle safety arrangements, bumpers, etc., can solve the problems of poor energy absorption effect of anti-collision beams, damage of other parts, single structure of anti-collision beams, etc., and achieve energy absorption Good effect, reduced maintenance cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

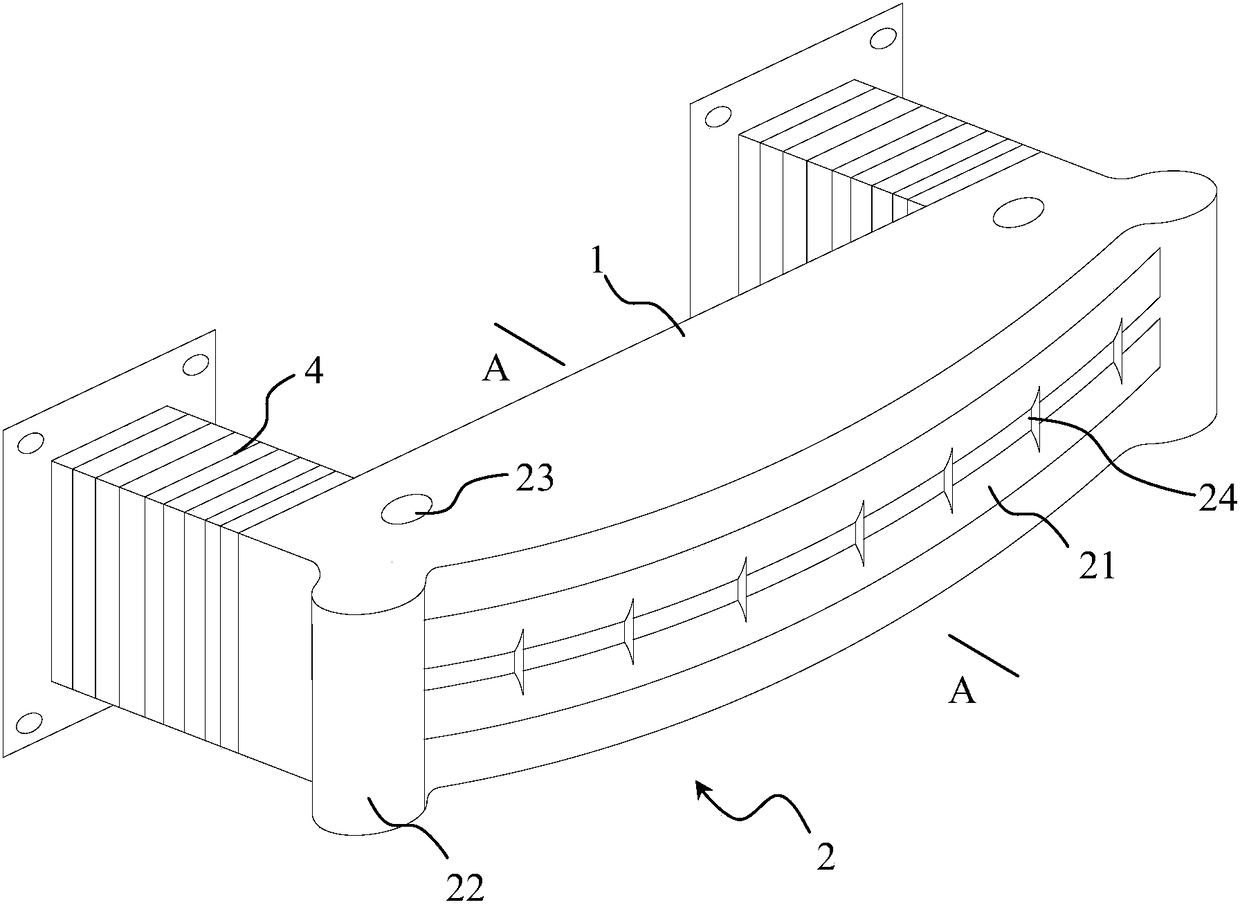

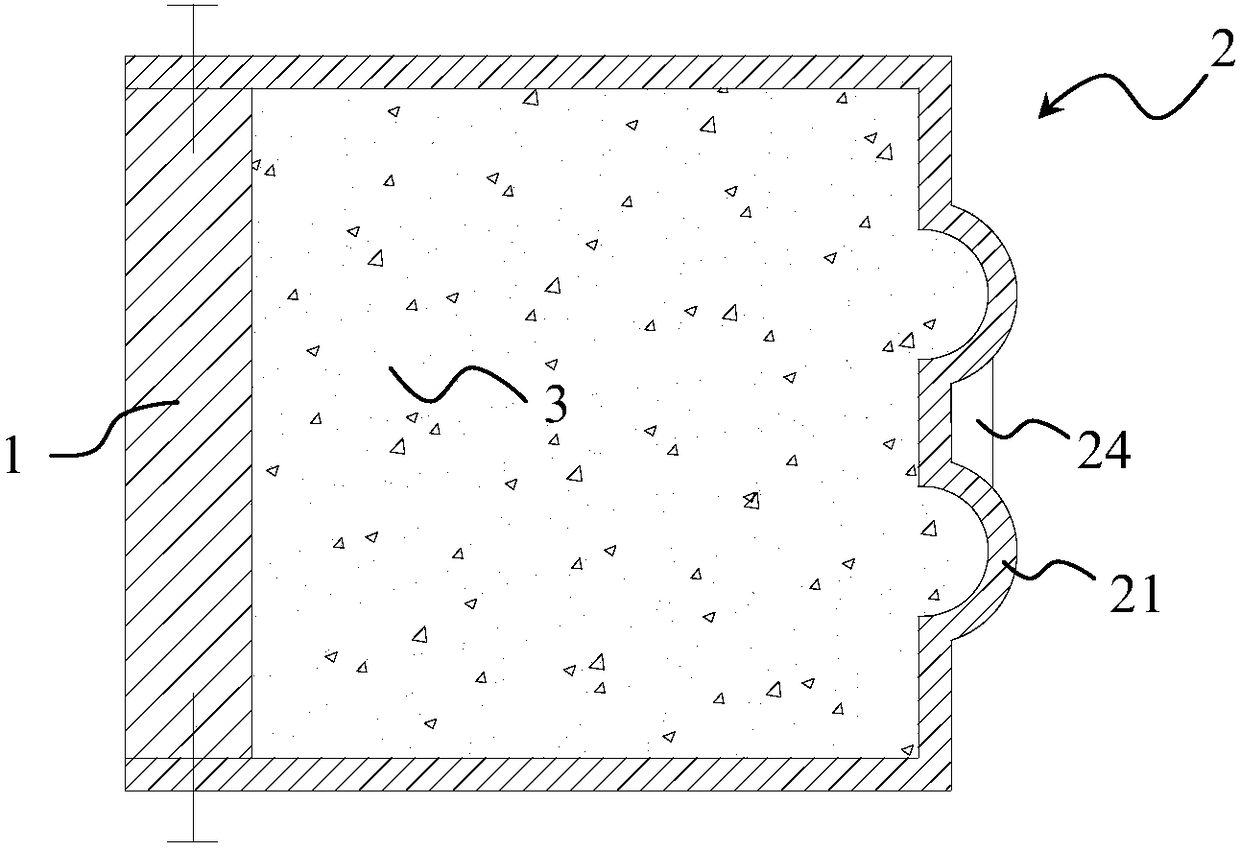

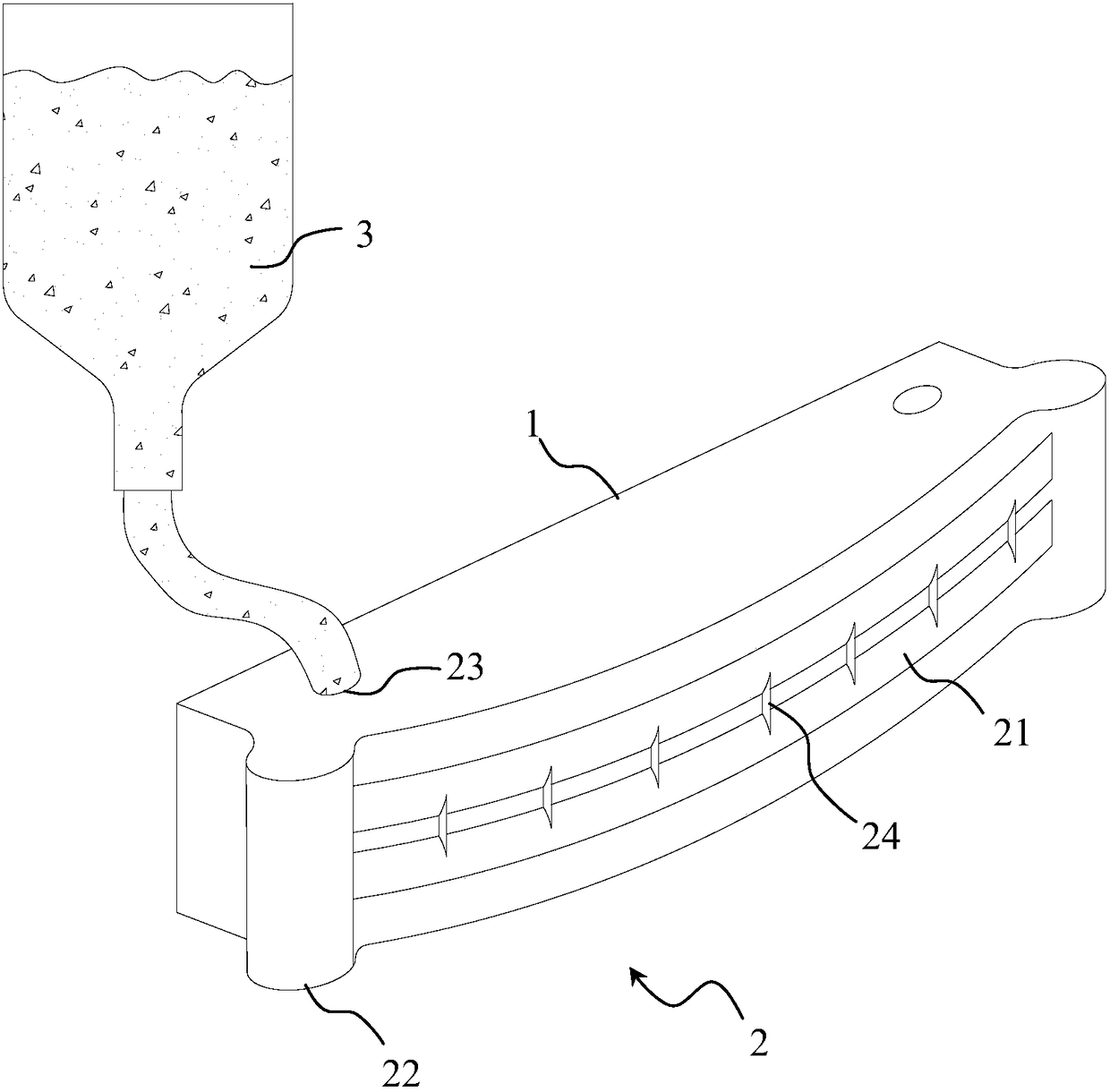

[0029] Such as figure 1 , figure 2 and image 3 As shown, this embodiment discloses an automobile anti-collision beam, which includes a beam 1 and an energy-absorbing board 2 . The length direction of the energy-absorbing plate 2 is an outwardly convex curved surface. When a collision occurs, the curved surface design of the energy-absorbing plate 2 enables the energy-absorbing plate 2 to have greater elastic deformation, which can remove part of the impact force, thereby strengthening the energy-absorbing plate. 2 compression capacity; the energy-absorbing plate 2 is provided with two arc-shaped structures 21 that protrude outward along the length direction and are arranged up and down. The arc-shaped structures 21 are first deformed by the impact force during the impact process, and other positions successively The impact force is sensed to bear the deformation of the arc-shaped structure. When the impact force carried by other positions reaches the limit, other positions...

Embodiment 2

[0039] The components, process parameters and process flow included in this embodiment are basically the same as those in Embodiment 1, except that X is made of aluminum powder. Compared with Example 1, in this example, aluminum powder is used instead of iron powder, which reduces the hardness of the buffer material 3 but improves the elasticity of the buffer material 3 .

Embodiment 3

[0041] The components, process parameters and process flow included in this embodiment are basically the same as in embodiment 1, except that the buffer material 3 is 5 wt% acrylonitrile, 30 wt% butadiene, 40 wt% styrene, 10wt% of X, 5wt% of nickel powder and 10wt% of carbon fiber particles are used for compounding. Compared with Example 1, in this example, the weight percentage of acrylonitrile decreases, and its components all increase, which improves the strength and elasticity of the cushioning material 3 as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com