Automatic routing inspection device for long-distance belt conveyor

A belt conveyor, automatic inspection technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc. The problem of long running distance of the type conveyor is solved, and the effect of small interference of site environmental factors, wide practicability and simple structure is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings.

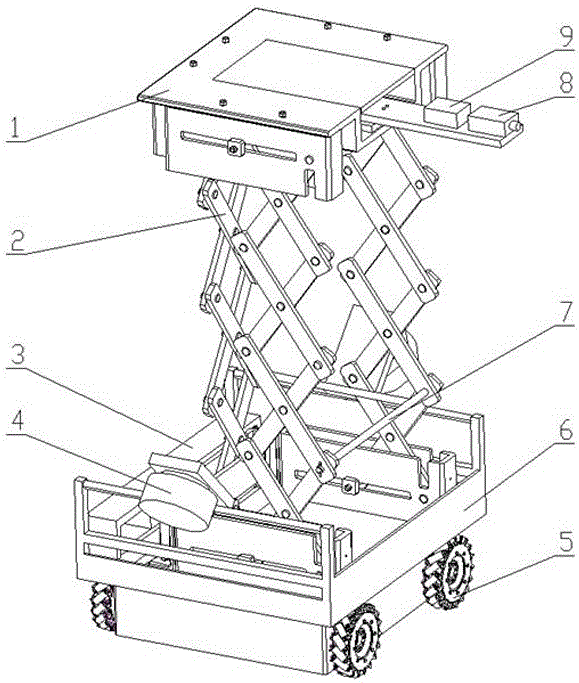

[0011] Such as figure 1 As shown, the automatic inspection device of the long-distance belt conveyor of the present invention includes a platform 1, three sets of four-stage scissor linkages 2, a mecanum wheel 5, a vehicle frame 6, a connecting rod 7, and a wireless communication module , a data processing module; the vehicle frame 6 is provided with a CCD camera 4, a DSP processor, a stepping motor, and a first linear motor 3; the mecanum wheel 5 is connected with a stepping motor; the three groups of four One end of the scissor linkage mechanism 2 is connected to the first linear motor 3, and the other end is connected to the platform 1, and three sets of four-stage scissor linkage mechanisms 2 are connected through the connecting rod 7; the platform 1 is provided with an infrared The imager 8, the sound sensor 9, the second linear motor, and the flat panel, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com