Novel clean environment-friendly coagulant and production method thereof

A clean and environmentally friendly coagulant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., can solve problems such as polluted water, slow coagulation speed of coagulant, and poor detackification effect , to achieve the effect of fast coagulation speed, excellent detackification effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

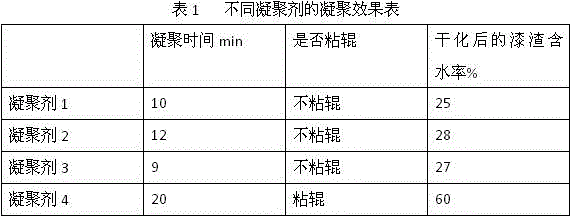

[0029] Embodiment 1 Prepare coagulant 1 with the method of the present invention

[0030] Prepare coagulant with the method of the present invention, step is as follows:

[0031] a. Add baking soda and soda ash to the water and stir for 5 minutes to adjust the pH of the solution to 8;

[0032] b. Add modified starch to the solution in step a, stir for 10 minutes, and adjust the pH of the solution to 5;

[0033] c, add modified chitosan towards step b solution, stir for 15min, until forming a stable suspension;

[0034] d. Add organically modified bentonite to the suspension in step d, stir for 6 hours, adjust the pH of the solution to 7, and prepare a new clean and environmentally friendly coagulant finished product 1 after bagging.

[0035] The composition of adding each raw material is: organically modified bentonite 15%, modified chitosan 20%, modified starch 12%, soda ash 5%, baking soda 2%, water 46%.

Embodiment 2

[0036] Embodiment 2 Prepare coagulant 2 with the method of the present invention

[0037] Prepare coagulant with the method of the present invention, step is as follows:

[0038] a. Add baking soda and soda ash to the water and stir for 10 minutes to adjust the pH of the solution to 11;

[0039] b. Add modified starch to the solution in step a, stir for 20 minutes, and adjust the pH of the solution to 7;

[0040] c, add modified chitosan towards the step b solution, stir for 20min, until forming a stable suspension;

[0041] d. Add organically modified bentonite to the suspension in step d, stir for 7 hours, adjust the pH of the solution to 8, and prepare a new clean and environmentally friendly coagulant finished product 2 after bagging.

[0042] The composition of adding each raw material is: by weight percentage, organically modified bentonite 13%, modified chitosan 20%, modified starch 10%, soda ash 5%, baking soda 2%, water 50%.

Embodiment 3

[0043] Embodiment 3 Prepare coagulant 3 with the method of the present invention

[0044] Prepare coagulant with the method of the present invention, step is as follows:

[0045] a. Add baking soda and soda ash to the water and stir for 10 minutes to adjust the pH of the solution to 8;

[0046] b. Add modified starch to the solution in step a, stir for 15 minutes, and adjust the pH of the solution to 6;

[0047] c, add modified chitosan towards the step b solution, stir for 18min, until forming a stable suspension;

[0048] d. Add organically modified bentonite to the suspension in step d, stir for 6 hours, adjust the pH of the solution to 7, and prepare a new clean and environmentally friendly coagulant finished product 3 after bagging.

[0049] The composition of adding each raw material is: organically modified bentonite 10%, modified chitosan 15%, modified starch 12%, soda ash 5%, baking soda 2%, water 56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com