Super low-heat ecological cement

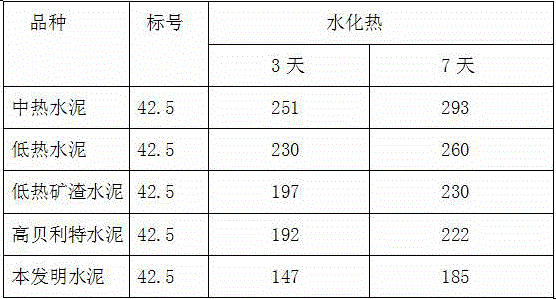

An ecological cement and ultra-low heat technology, applied in the field of building materials, can solve the problems of low early strength of low-heat cement, seldom produced and applied, and difficult to meet the construction speed, etc., to achieve simple production process, strong anti-freezing ability, and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The ultra-low heat ecological cement product of the present invention is obtained by uniformly mixing 10% of Portland cement clinker or finished product with 90% of one of basalt powder, andorite powder, diabase powder and gabbro powder.

Embodiment 2

[0021] The ultra-low heat ecological cement product of the present invention is obtained by uniformly mixing 20% of Portland cement clinker or finished product with 80% of one of basalt powder, andorite powder, diabase powder and gabbro powder.

Embodiment 3

[0023] Evenly mix 40% of Portland cement clinker or finished product with 60% of one of basalt powder, andorite powder, diabase powder and gabbro powder to obtain the ultra-low heat ecological cement product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com