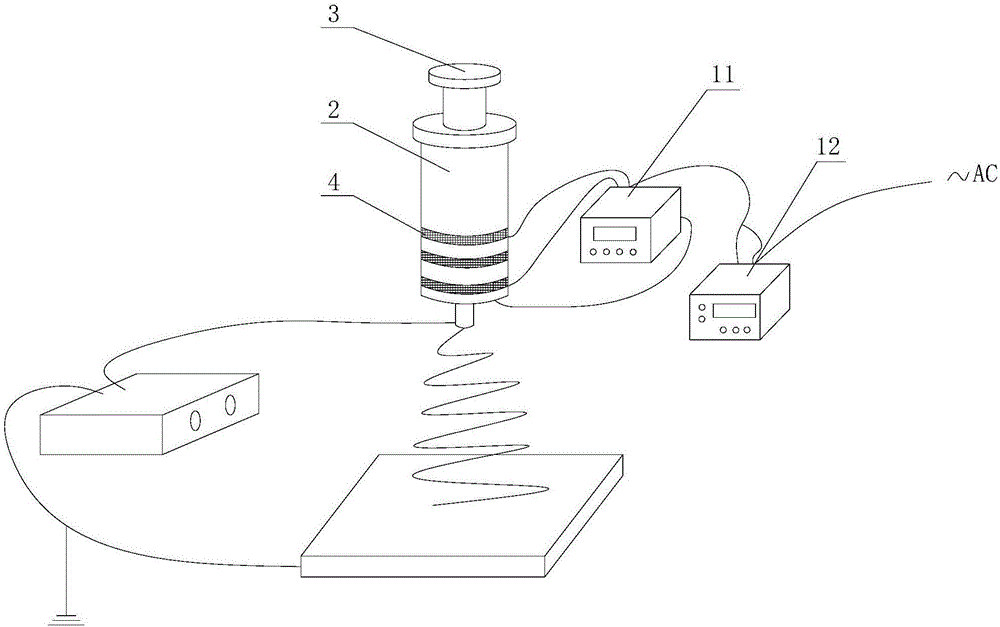

Hot-melting electrostatic integrated spinning machine

An electrostatic spinning and spinning machine technology, which is applied in the field of hot-melt electrostatic integrated spinning machine equipment, can solve the problems of long dissolution time, less pore size fibers, easy contact of the solution, etc., to improve safety, enhance strength, prevent solidified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

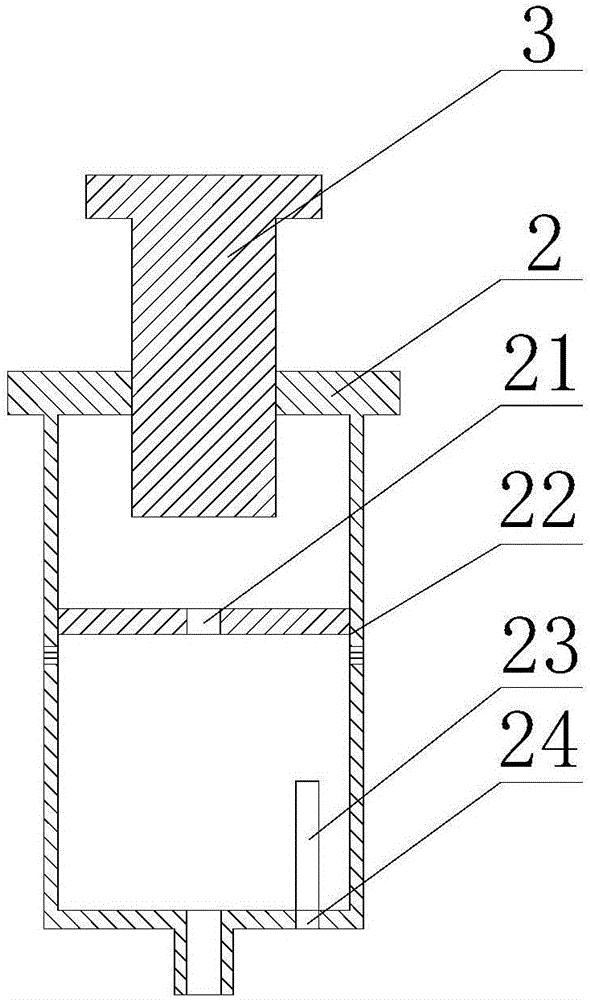

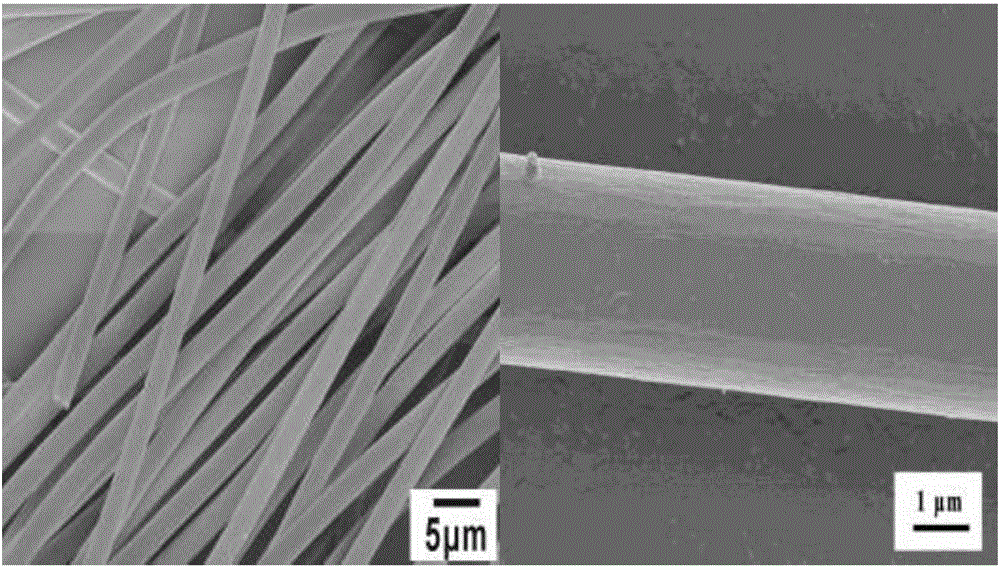

Embodiment 1

[0037] (1) Put the weighed 5g polystyrene polymer particles into the quartz syringe 2, and the upper and lower parts of the quartz syringe 2 are fixedly connected by the threaded screw port provided on the quartz syringe 2, so that the flexibility and The glass fiber heating belt 4 with better heat-resistant effect is wrapped around the lower half of the quartz syringe 2, through the thermocouple 23 probe mounting hole 24 opened at the bottom of the quartz syringe 2, the K-type thermocouple 23 and the K-type thermocouple are installed. The pair 23 is arranged in the middle of the sample in the quartz syringe 2;

[0038](2) Plug in the power supply of the temperature control device, set the temperature of the temperature controller 11, adjust it to 250°C, and set the timing time of the timer 12 to 30 minutes;

[0039] (3) Set the flow pump, and the propulsion speed is 1ml / h;

[0040] (4) Adjust the electrospinning device. The electrospinning device includes a spinneret, a spin...

Embodiment 2

[0043] (1) Put the weighed 5g polystyrene polymer particles into the quartz syringe 2, and the upper and lower parts of the quartz syringe 2 are fixedly connected by the threaded screw port provided on the quartz syringe 2, so that the flexibility and The glass fiber heating belt 4 with better heat-resistant effect is wrapped around the lower half of the quartz syringe 2, through the thermocouple 23 probe mounting hole 24 opened at the bottom of the quartz syringe 2, the K-type thermocouple 23 and the K-type thermocouple are installed. The pair 23 is arranged in the middle of the sample in the quartz syringe 2;

[0044] (2) Plug in the power supply of the temperature control device, set the temperature of the temperature controller 11, adjust it to 230°C, and set the timing time of the timer 12 to 30 minutes;

[0045] (3) Set the flow pump, and the propulsion speed is 0.1ml / h;

[0046] (4) Adjust the electrospinning device. The electrospinning device includes a spinneret, a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com