Gas transmission pipeline leakage detection system based on acoustic method

A gas pipeline and leak detection technology, applied in the field of gas pipeline leak detection system, can solve the problem of not being able to effectively seize the best time to deal with leakage accidents, poor gas pipeline leak detection and positioning effect, gas pipeline leak detection system, etc. problems, to achieve the effect of strong adaptability, fast response time, and simplified system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

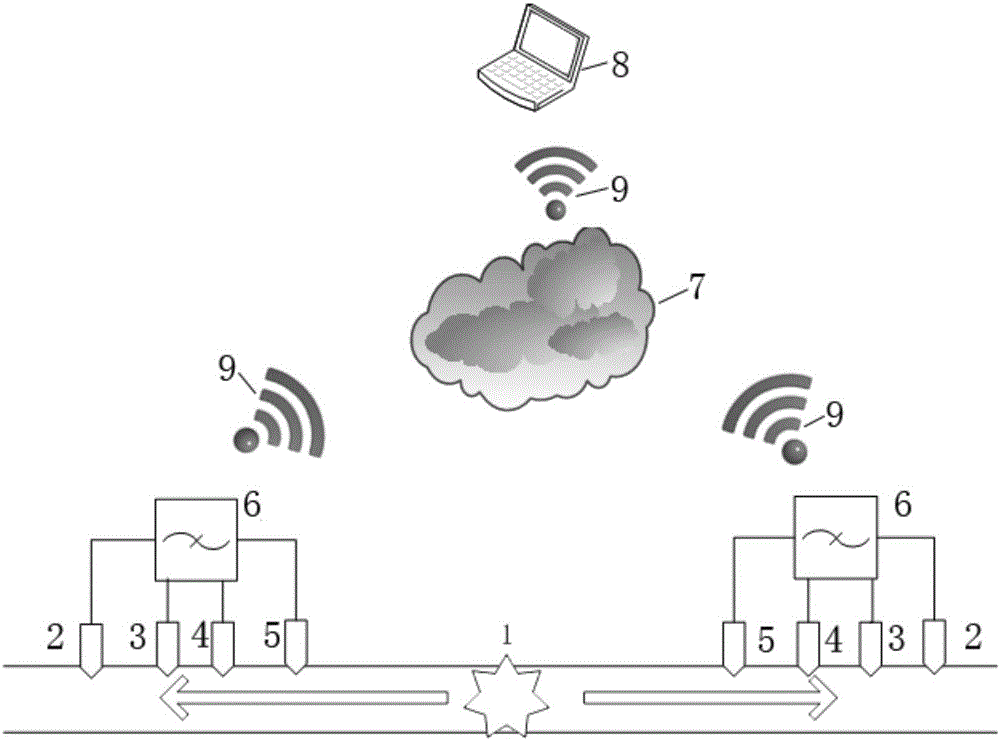

[0042] Such as Figure 1 to Figure 3 As shown, a gas pipeline leakage detection system based on the acoustic wave method includes a user terminal 8, a cloud server 7 and several detection sections arranged along the gas pipeline, each detection section is provided with two low-frequency acoustic wave sensors 2 , two temperature sensors 3 , two density sensors 4 , two pressure sensors 5 and two digital network transmitters 6 .

[0043] Two low-frequency acoustic wave sensors 2 in each detection section are respectively arranged at the two ends of the gas transmission pipeline in the detection section, and each low-frequency acoustic wave sensor 2 is used to collect the low-frequency acoustic wave signal in the gas transmission pipeline in the detection section, and The col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com