Intelligent temperature control water-mixing center

An intelligent temperature control and water mixing technology, which is applied to household heating, space heating and ventilation details, heating fuel, etc., can solve the problems of increasing water flow resistance, small flow, slow water mixing effect, etc., to save energy , the effect of reducing manufacturing costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

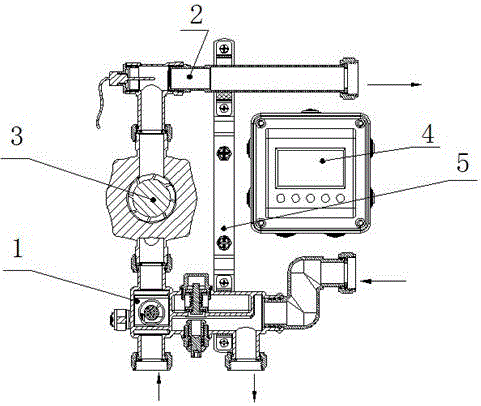

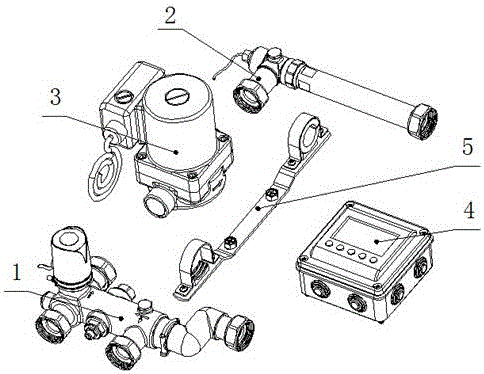

[0030] Such as Figure 1-5 As shown, an intelligent temperature-controlled water mixing center is applied to the floor heating system. The floor heating system includes a wall-hung boiler, a heating pipe, a water separator, a floor heating pipe, a water collector, and a water return pipe. The water mixing center includes a water mixing center Valve 1, circulation pump 2, water supply tee connection assembly 3 and temperature control panel 4;

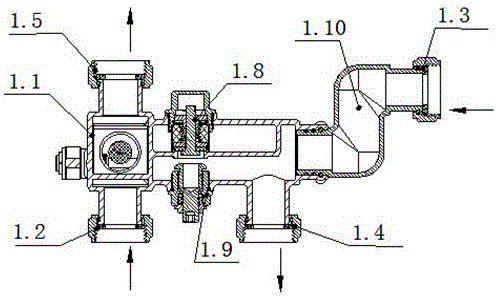

[0031] The water mixing valve 1 includes a main body 1.1, which is provided with a water supply port 1.2, a primary water return port 1.3, a secondary water return port 1.4 and a first circulation pump interface 1.5, and the water supply port 1.2 is connected to the heating pipeline, and the water supply port 1.2 and the first A water mixing valve core 1.6 is installed between the circulation pump interface 1.5, and the electric heating actuator 1.7 is connected to the mixing water valve core 1.6, and a check valve core 1.8 and a return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com