A kind of ultra-thin heat pipe and its port sealing method

An ultra-thin heat pipe and heat pipe technology, which is applied in the field of heat pipes, can solve the problems of heat pipe use restrictions, occupying installation space, etc., and achieve the effect of reducing space and overcoming technical barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

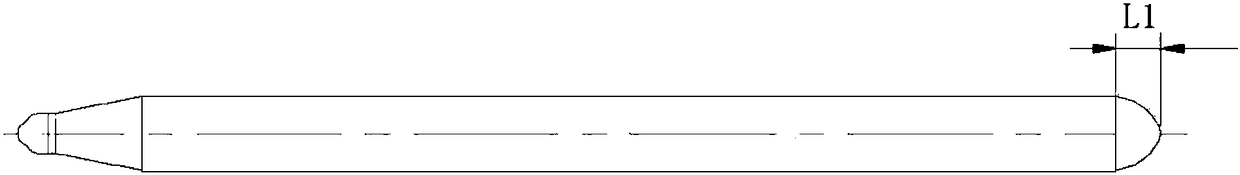

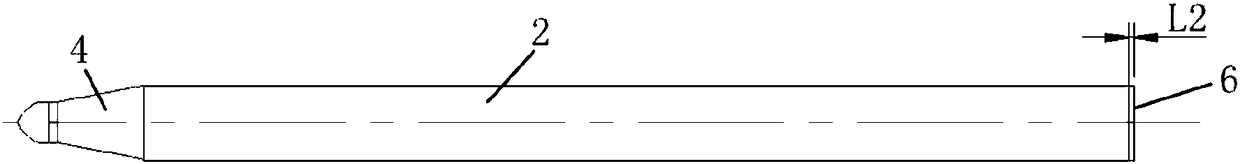

[0027] This embodiment discloses a method for sealing the end of an ultra-thin heat pipe, using this method to prepare such figure 2 In the heat pipe with the structure shown, one end of the heat pipe body 2 is a closed end 4, and the other end is a sealed end 6. In the present invention, the heat pipe body 2 is preferably a copper pipe, and the heat conductivity of the copper pipe is high. The sealing method of the example can prepare an ultra-thin heat pipe whose wall thickness is controlled below 0.6 mm, and is suitable for use in a highly integrated PCB circuit. The port sealing method includes the following steps,

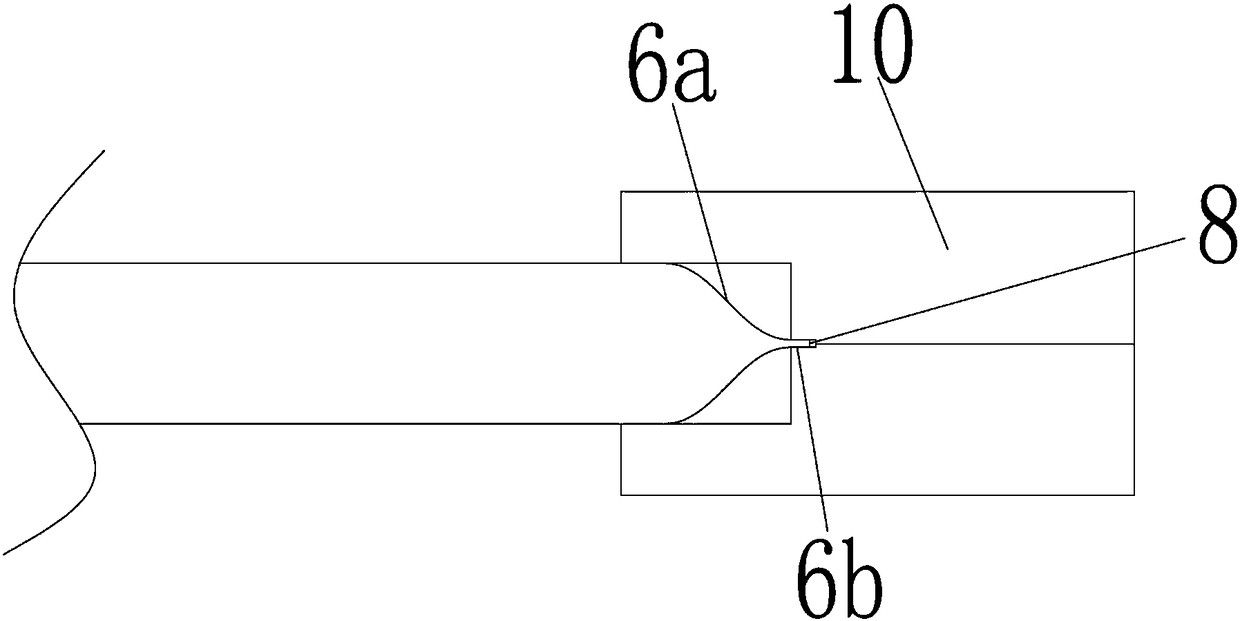

[0028] (1) Sealing end pressing: Use a pressing tool to press the sealing end 6 of the heat pipe body 2, so that the inner wall surfaces of the sealing end 6 are bonded together. After pressing, the sealing end 6 forms two parts, which are gradually The shrinkage part 6a and the flattened part 6b, the length L2 of the sealing end 6 after pressing is less than...

Embodiment 2

[0034] Such as figure 2 As shown, the present embodiment provides a kind of ultra-thin heat pipe, comprises tubular body, and the wall thickness of tubular body is 0.6mm, preferably adopts the copper tube with high thermal conductivity, one end of described tubular body is closed end 4, and its other end is The sealing end 6 is sealed by the above sealing method. The length of the sealing end 6 after sealing is less than or equal to 2mm. The length direction of the pipe body is even, and after sealing, a closed cavity is formed inside the tubular body, and the closed cavity is filled with a phase change fluid medium.

[0035] The wall thickness of the heat pipe of the present invention is controlled below 0.6 mm, and the length of the sealing end 6 is controlled below 0.2 mm, which can be used in products with high PCB integration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com