Non-contact throttle position sensor

A throttle position, non-contact technology, applied in the direction of converting sensor output, using electric/magnetic devices to transmit sensing components, instruments, etc., can solve the problem of not meeting the output accuracy requirements of the throttle position sensor, fast wear of the sealing ring, Insufficient output accuracy and other problems, to achieve the effect of novel structure, improved accuracy, and good working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

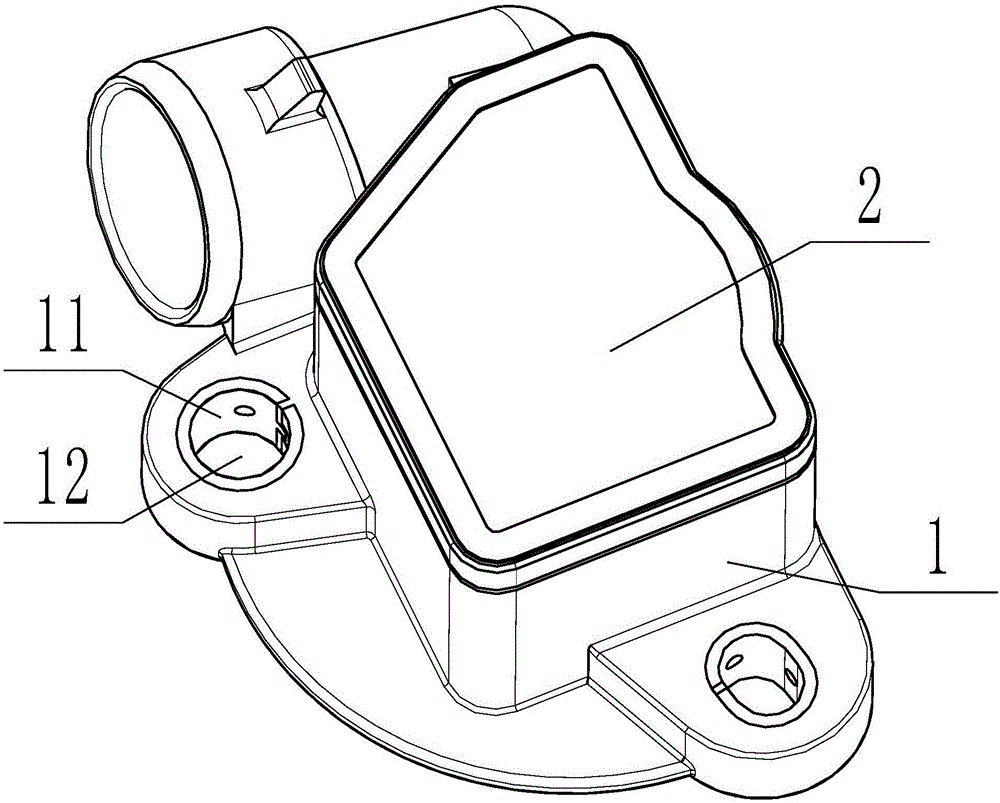

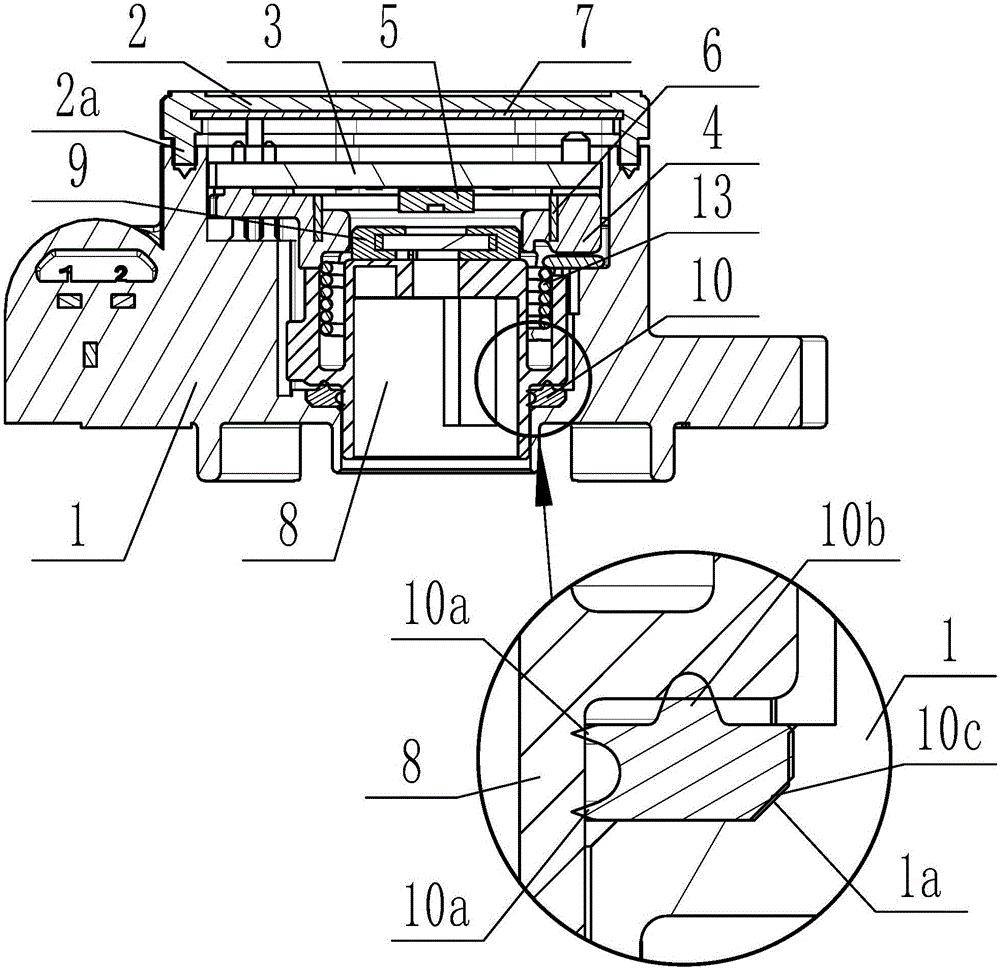

[0030] Such as figure 1 and figure 2 As shown, a non-contact throttle position sensor includes a housing 1 and a cover plate 2 fastened on the housing 1. A rotor 8, a limiter, and a rotor 8 are sequentially arranged inside the housing 1 from bottom to top. The bit board 4 and the circuit board 3 are provided with a reset twist yellow 13 for resetting the rotor 8. One end of the reset twist yellow 13 is overlapped with the rotor 8, and the other end is connected with the housing 1 lap.

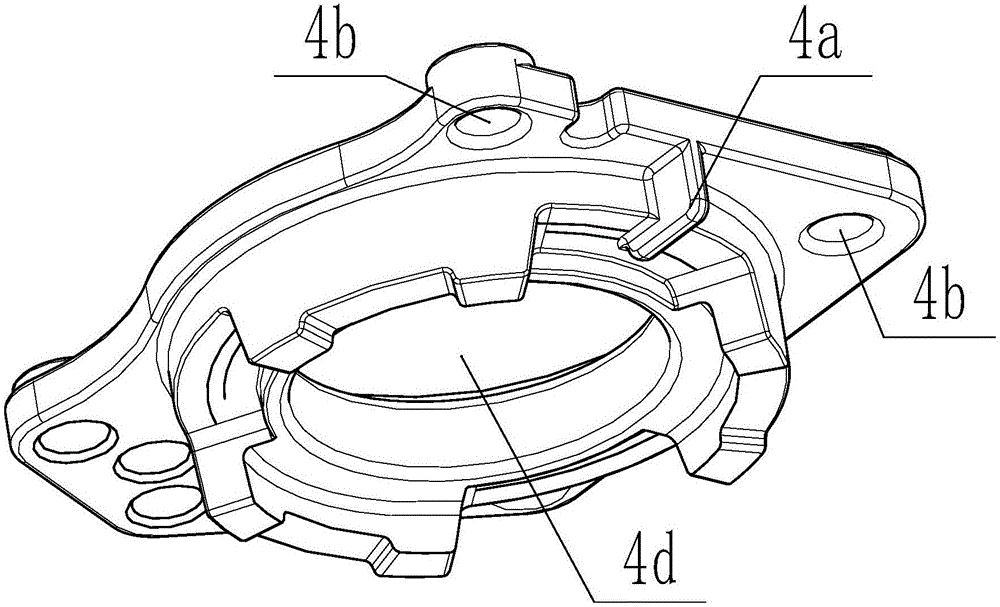

[0031] See figure 2 , Figure 4 and Figure 5 , the rotor 8 is provided with a magnetic element 9, and the lower surface of the circuit board 3 is provided with a Hall chip 5 adapted to the magnetic element 9, and a gap is left between the Hall chip 5 and the magnetic element 9. gap, the limiting plate 4 has a hollow portion 4d, and the Hall chip 5 and the magnetic ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com