Test fixture for low pass filter

A low-pass filter and test fixture technology, applied in instruments, measuring devices, measuring electrical variables, etc., can solve problems such as inability to easily complete device testing, error-prone testing processes, and inability to complete welding, and achieve convenient and fast loading, unloading and maintenance. , the effect of a wide range of tests and a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

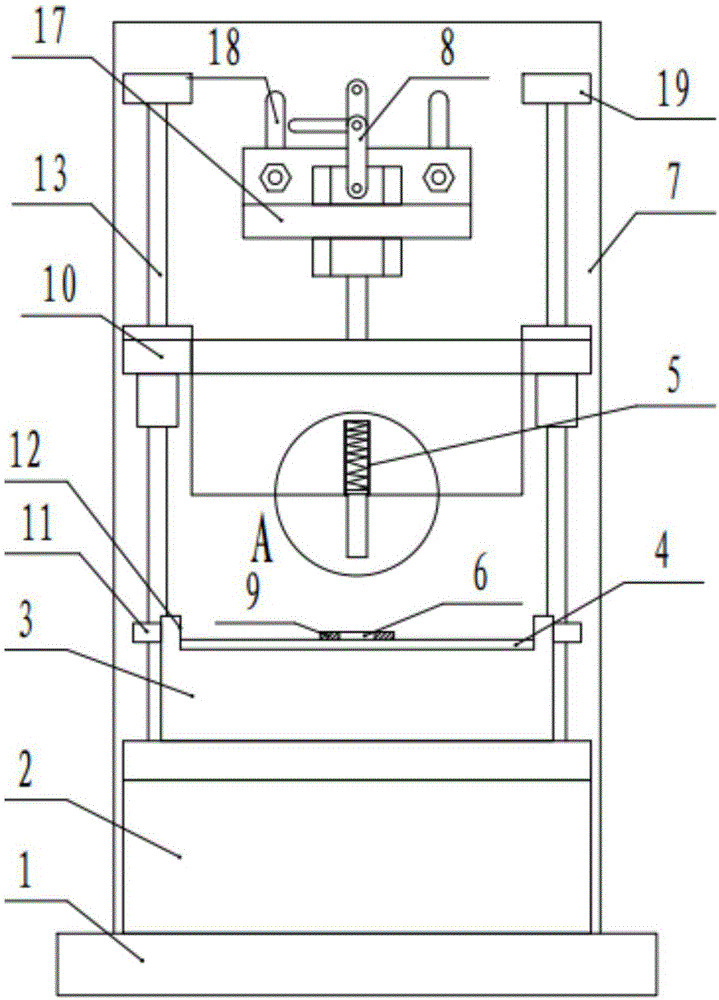

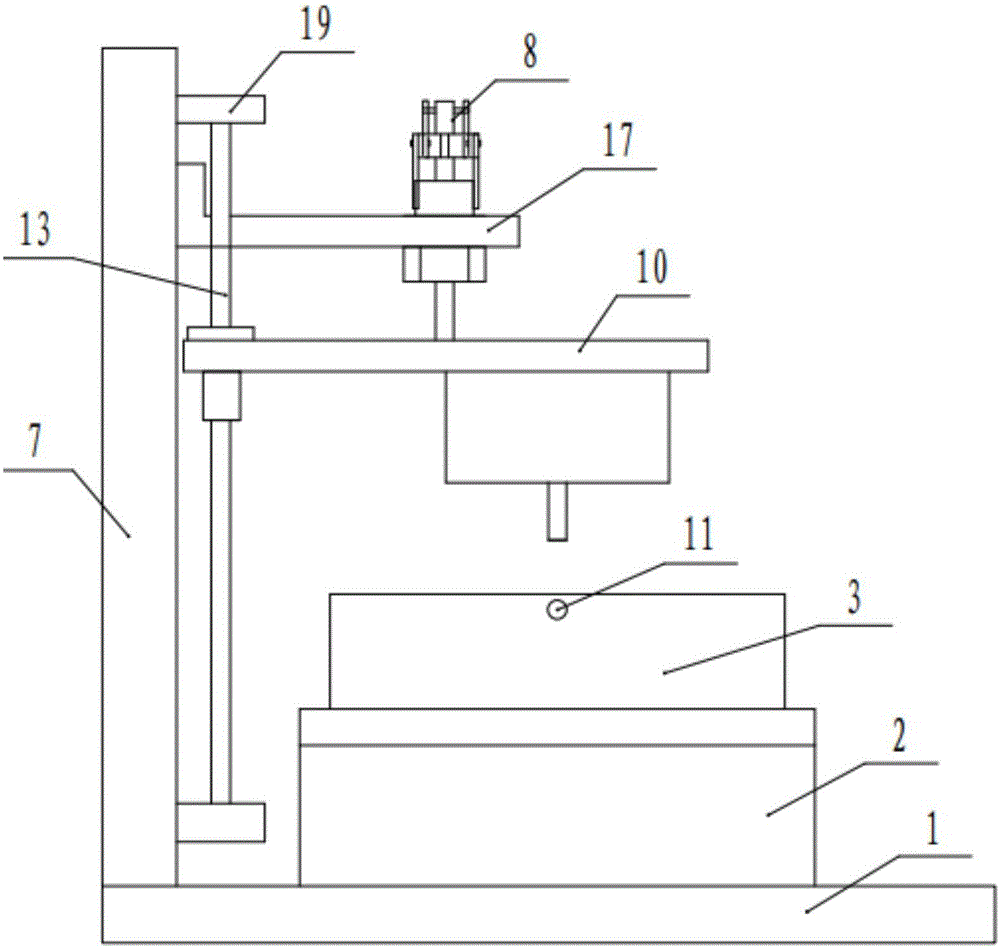

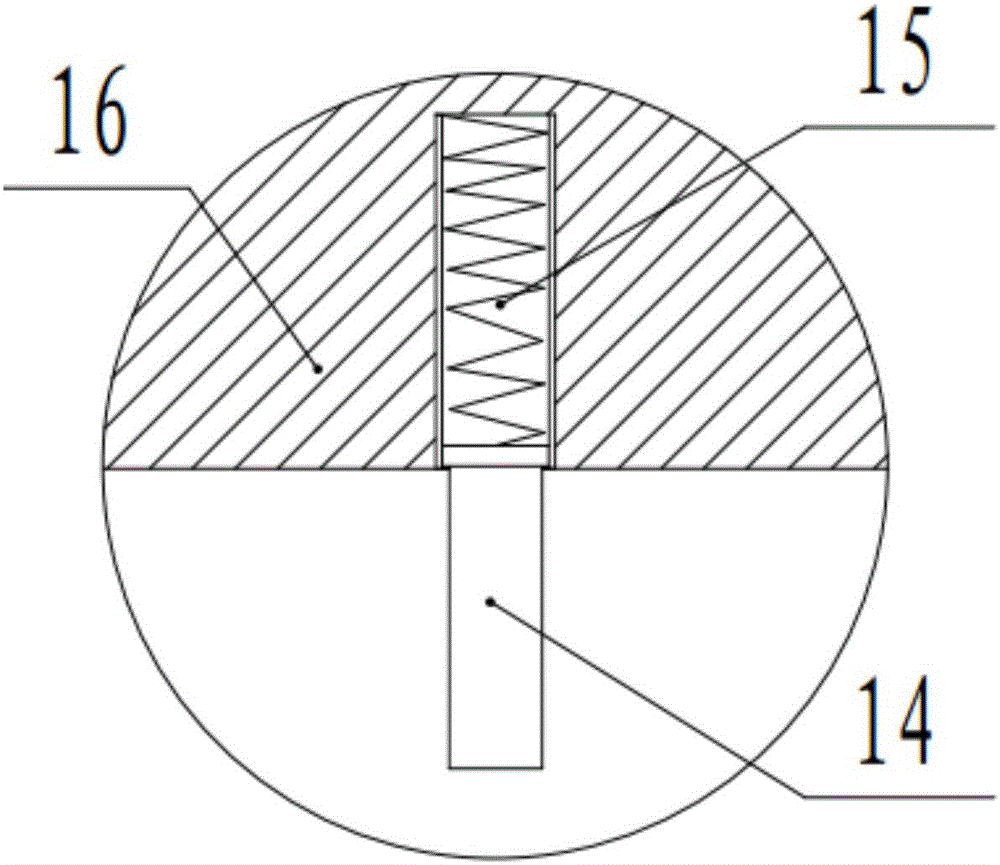

[0018] Example: such as Figure 1-Figure 4 As shown, a low-pass filter test fixture includes a micrometer slide 2, an adapter seat 3, a circuit board 4, and a pressure spring clamp 5. The upper end surface of the adapter seat 3 is provided with a groove 12, and its lower end surface is fixedly connected On the micrometer slide 2, the micrometer slide 2 is fixed on the base 1 and can adjust the XY direction of the adapter seat 3, and the circuit board 4 and the positioning plate 9 are fixedly placed in the groove 12 from bottom to top, and the circuit The plate 4 is connected to the monitoring equipment through wires, and the pressure spring clamp 5 is fixedly connected to the slide plate 10. The slide plate 10 is connected to the rear side plate 7 through two damping shafts 13 and can move axially along the slide rail 13. The positioning plate 9 is set There is a limit slot 6 for placing the filter under test, and the pressing piece spring clamp 5 faces the limit slot 6 after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com