Cleaning composition for photolithography and method of forming photoresist pattern using the same

A technology for cleaning compositions and photoresist patterns, applied in the field of forming photoresist patterns and cleaning compositions necessary for photoresist patterns, can solve problems affecting final products, increase production costs, etc., and achieve the goal of reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

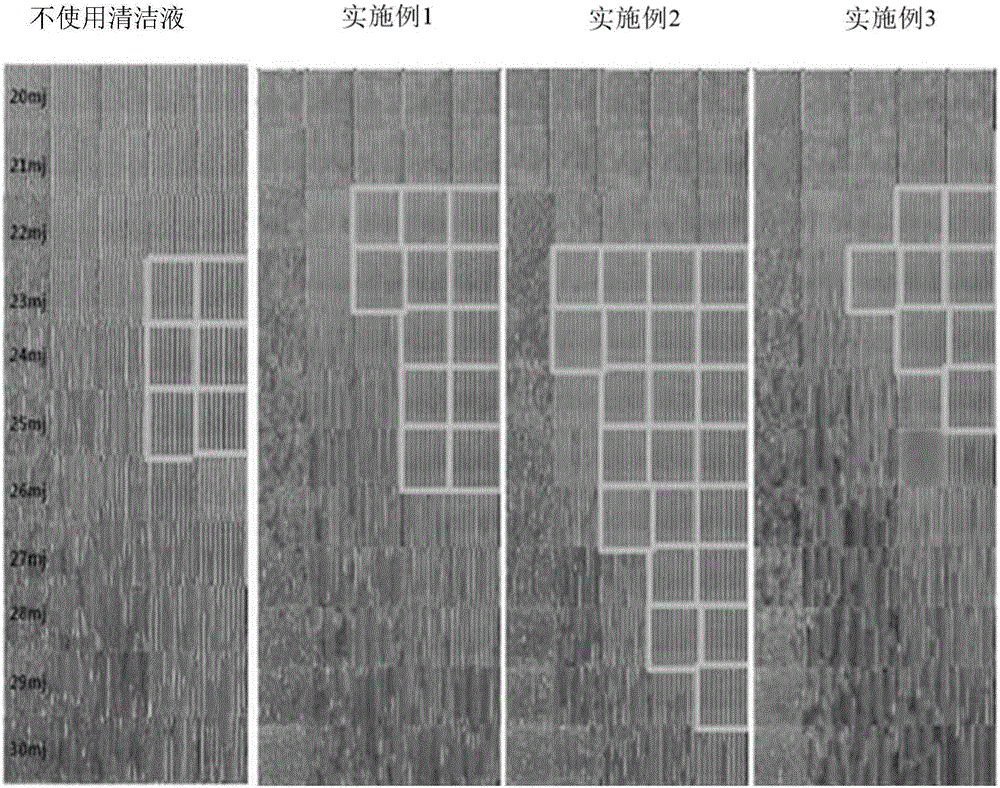

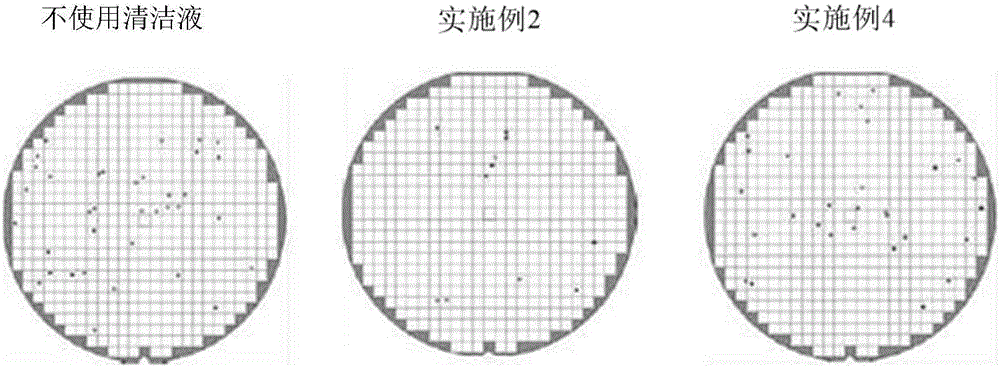

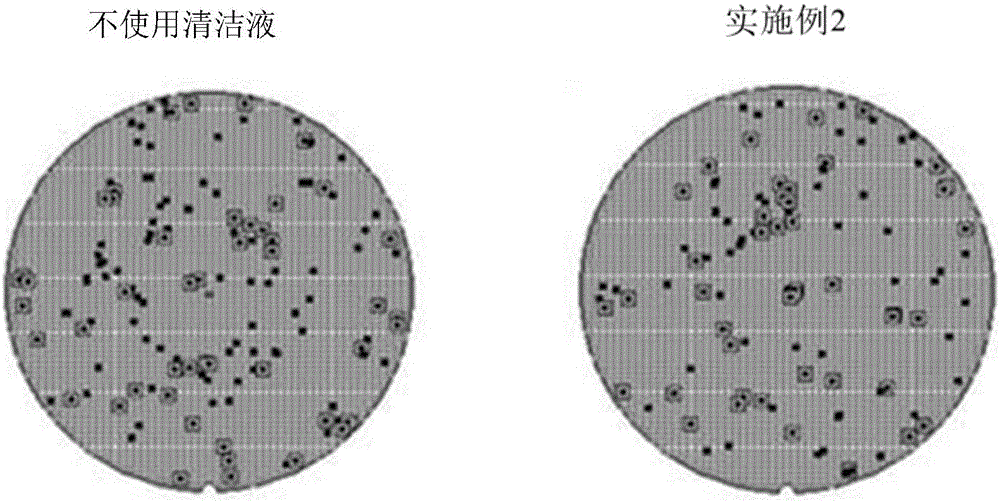

Embodiment 1 to 3

[0055] Examples 1 to 3: Preparation of cleaning compositions

Embodiment 1

[0057] The compound of chemical formula 1 (wherein R is H, x is 12, y is 7, z is 0) with the compound of chemical formula 1 of 0.01g, the tetrabutylammonium hydroxide of 0.01g and the isopropanol of 1g are mixed with the deionized water of 98.98g, generate Cleansing compositions.

Embodiment 2

[0059] The compound of chemical formula 1 (wherein R is H, x is 12, y is 9, z is 0) with the compound of chemical formula 1 of 0.01g, the tetrabutylammonium hydroxide of 0.01g and the isopropanol of 1g are mixed with the deionized water of 98.98g, generate Cleansing compositions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com