Multi-response parameter optimization method based on radial basis function neural network prediction model

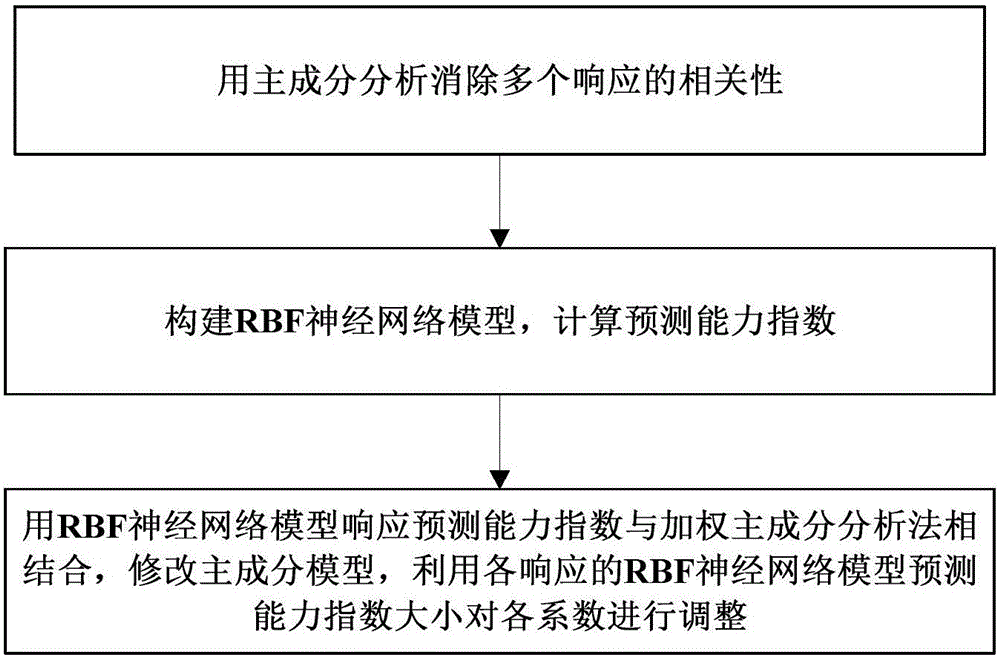

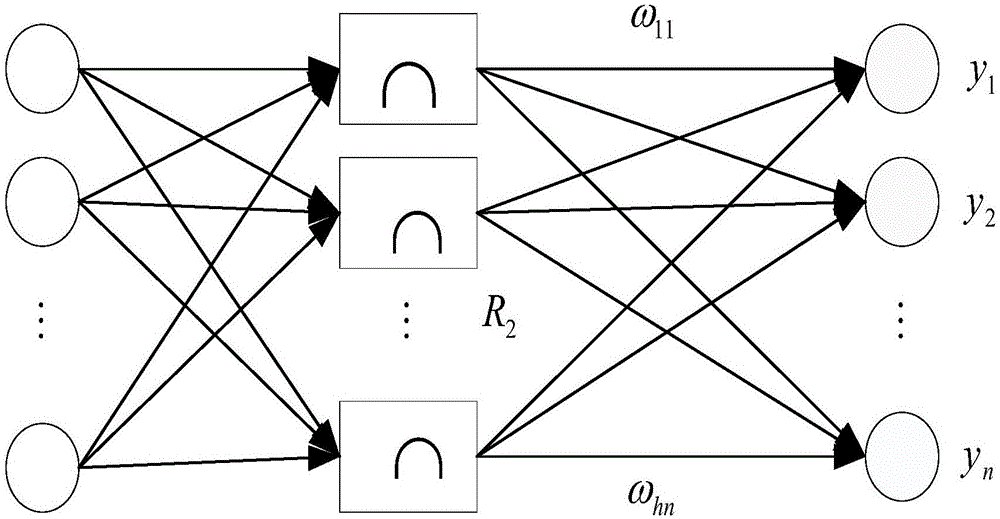

A neural network model and a neural network-based technology, which is applied in the field of multi-response parameter optimization of production processes, can solve the problem that polynomial parameter response surfaces cannot meet the requirements of process models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

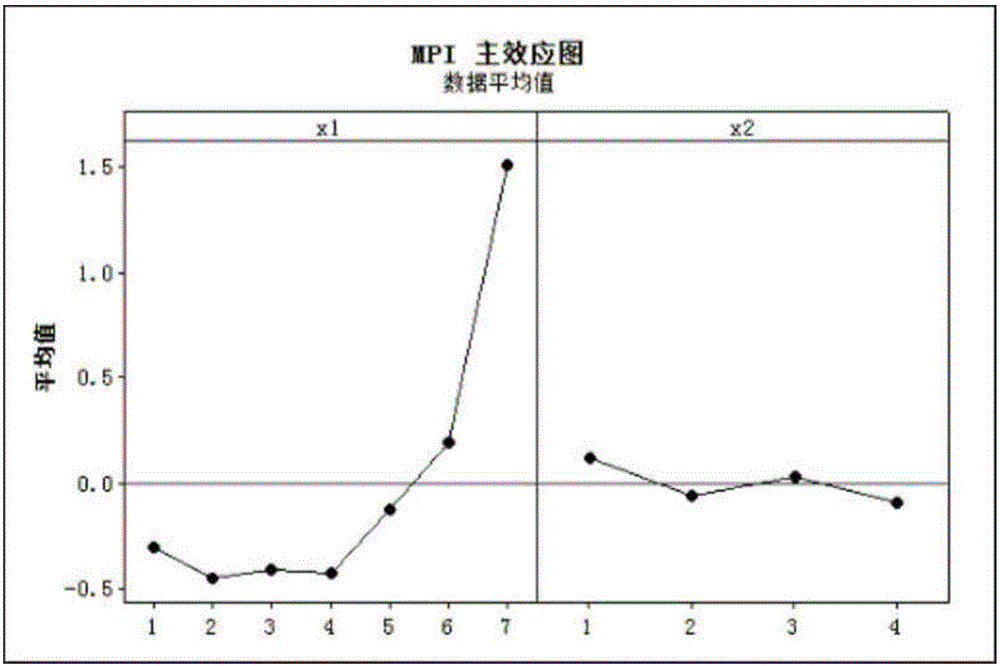

[0079] The production process of metallized polypropylene film capacitors is carried out in the atmosphere, and the thermal polymerization process is the key process to eliminate the air between the metallized film layers, which can achieve the purpose of improving the compactness and electrical performance stability of the capacitor. However, if the thermal polymerization is insufficient, the core will not be completely set and the film layer will be loose, which will lead to a decrease in the capacitor capacity and an increase in the loss tangent. Therefore, the temperature and time must be strictly controlled in the thermal polymerization process, and the optimal design of the two process parameters of temperature and time is expected to improve the two quality characteristic values of the capacitance value and the loss tangent value of the capacitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com