A dual main phase nd2fe14b-ce2fe14b composite permanent magnet and preparation method thereof

A technology of nd2fe14b-ce2fe14b, nd29.89gd0.61fe67al1.05zr0.4b1.05 is applied in the field of double main phase Nd2Fe14B-Ce2Fe14B composite permanent magnet and its preparation, which can solve the problem that the magnetic crystal anisotropy of single-phase alloy is low and cannot satisfy Market demand, the reduction of rare earth Nd content and other issues, to achieve the effect of improving the coercivity of the magnet, realizing cost control, high saturation magnetization and remanence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

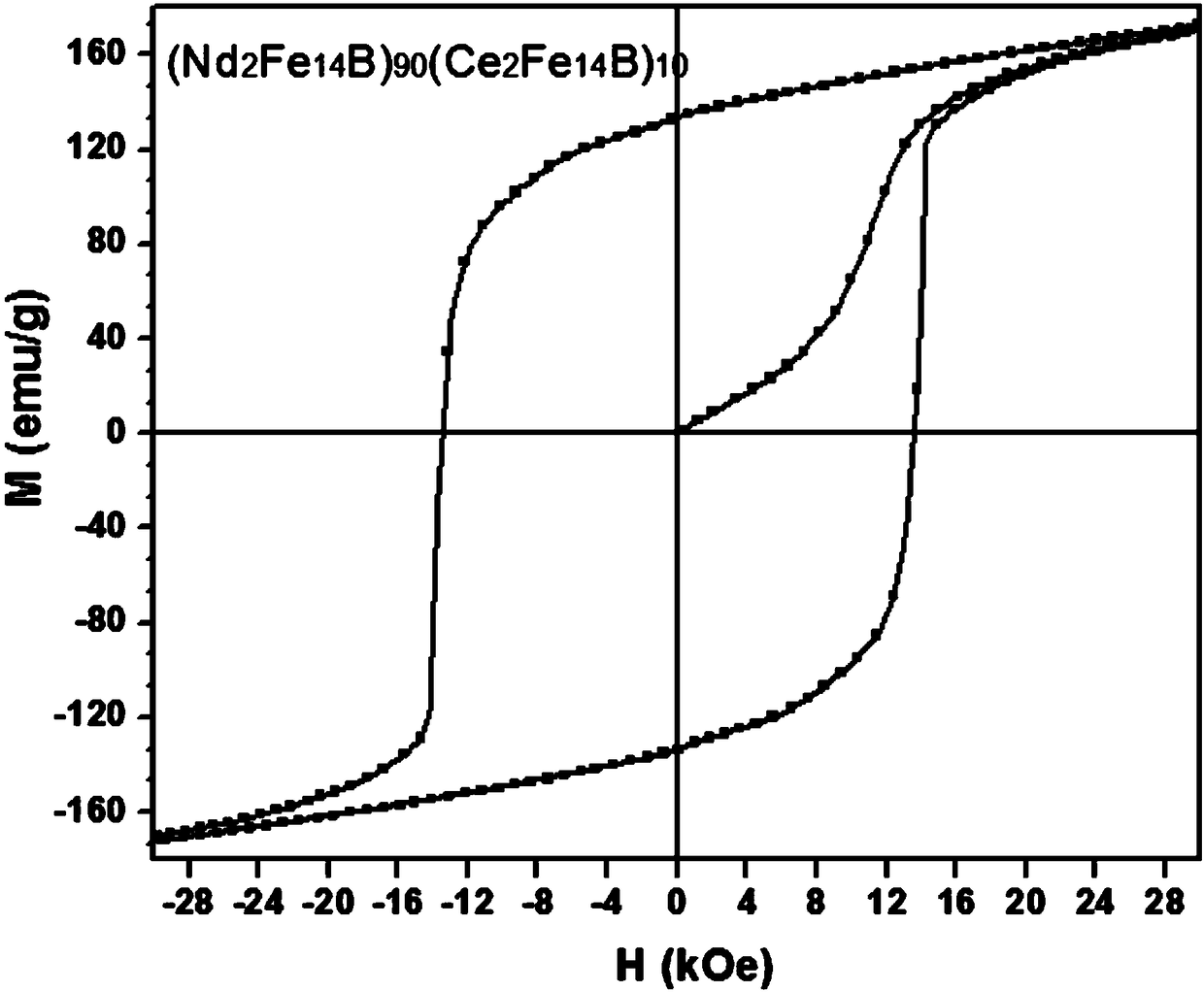

Embodiment 1

[0026] A dual main phase Nd 2 Fe 14 B-Ce 2 Fe 14 B composite permanent magnets, including Nd 2 Fe 14 B and Ce 2 Fe14 B, Nd 2 Fe 14 B and Ce 2 Fe 14 B mass fractions are 90% and 10% respectively ((Nd 2 Fe 14 B) 90 (Ce 2 Fe 14 B) 10 ) The dual main phase Nd 2 Fe 14 B-Ce 2 Fe 14 The preparation method of B composite permanent magnet, comprises the following steps:

[0027] (1) Take Nd, Ce, Gd, Fe, Al, Zr, B blocks with a purity of 99.99%, the mass fraction of Nd is 29.89%, the mass fraction of Gd is 0.61%, and the mass fraction of Fe is 67% , the mass fraction of Al is 1.05%, the mass fraction of Zr is 0.4%, and the mass fraction of B is 1.05% to prepare Nd-Gd-Fe-Al-Zr-B alloy; the mass fraction of Ce is 29.89%, and the mass fraction of Gd The fraction is 0.61%, the mass fraction of Fe is 67%, the mass fraction of Al is 1.05%, the mass fraction of Zr is 0.4%, and the mass fraction of B is 1.05% to prepare Ce-Gd-Fe-Al-Zr-B alloy, Place the weighed substances i...

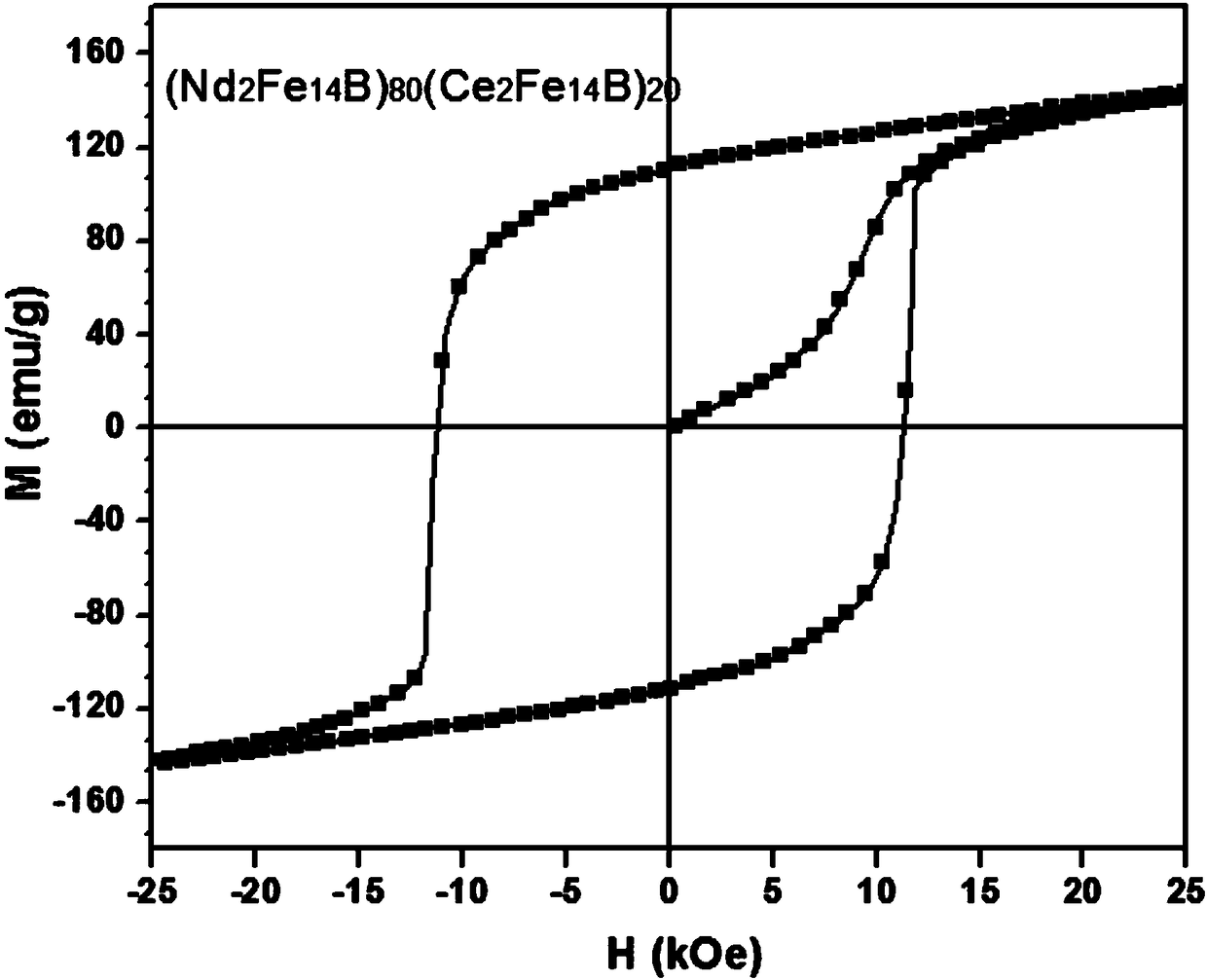

Embodiment 2

[0039] A dual main phase Nd 2 Fe 14 B-Ce 2 Fe 14 B composite permanent magnets, including Nd 2 Fe 14 B and Ce 2 Fe 14 B, Nd 2 Fe 14 B and Ce 2 Fe 14 B mass fractions were 80% and 20% (Nd 2 Fe 14 B) 80 (Ce 2 Fe 14 B) 20 . The dual main phase Nd 2 Fe 14 B-Ce 2 Fe 14 The preparation method of B composite permanent magnet, comprises the following steps:

[0040] (1) Take Nd, Ce, Gd, Fe, Al, Zr, B blocks with a purity of 99.99%, the mass fraction of Nd is 29.89%, the mass fraction of Gd is 0.61%, and the mass fraction of Fe is 67% , the mass fraction of Al is 1.05%, the mass fraction of Zr is 0.4%, and the mass fraction of B is 1.05% to prepare Nd-Gd-Fe-Al-Zr-B alloy; the mass fraction of Ce is 29.89%, and the mass fraction of Gd The fraction is 0.61%, the mass fraction of Fe is 67%, the mass fraction of Al is 1.05%, the mass fraction of Zr is 0.4%, and the mass fraction of B is 1.05% to prepare Ce-Gd-Fe-Al-Zr-B alloy, Place the weighed substances in a vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com