Physalis milk-flavored tofu and preparation method thereof

A tofu and milk-flavored technology, which is applied in the field of food processing, can solve the problems of adding and not yet seeing whey powder, etc., and achieve the effects of increasing milk flavor, good promotion and application value, and improving quality and grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The preparation process of the physalis milk-flavored tofu product provided by the present invention is generally as follows: raw soybeans→selection→soaking→rinsing→refining→raw pulp→cooking pulp→spotting→squatting brains→on brains→pressing and forming→cooling→finished product; The specific process is as follows:

[0036] (1) Soybean soaking, choose soybeans with full grain weight, no impurities, no insect eyes, no moldy deterioration, wash, soak at 20°C for 12-18 hours until the soybeans have no hard core, and ensure that the soybeans fully absorb water; after soaking, use clean water Rinse 3 times;

[0037] (2) Fermentation of whey. Fermentation of whey is carried out while soaking soybeans in step (1). In terms of mass ratio, whey powder and water are formulated into a solution at a ratio of 2:8, heated and boiled to sterilize, and cooled to 37°C, inoculate 0.1% lactic acid bacteria freeze-dried powder, ferment at 37°C for 8-10 hours until the acidity reaches 3%, th...

Embodiment 2

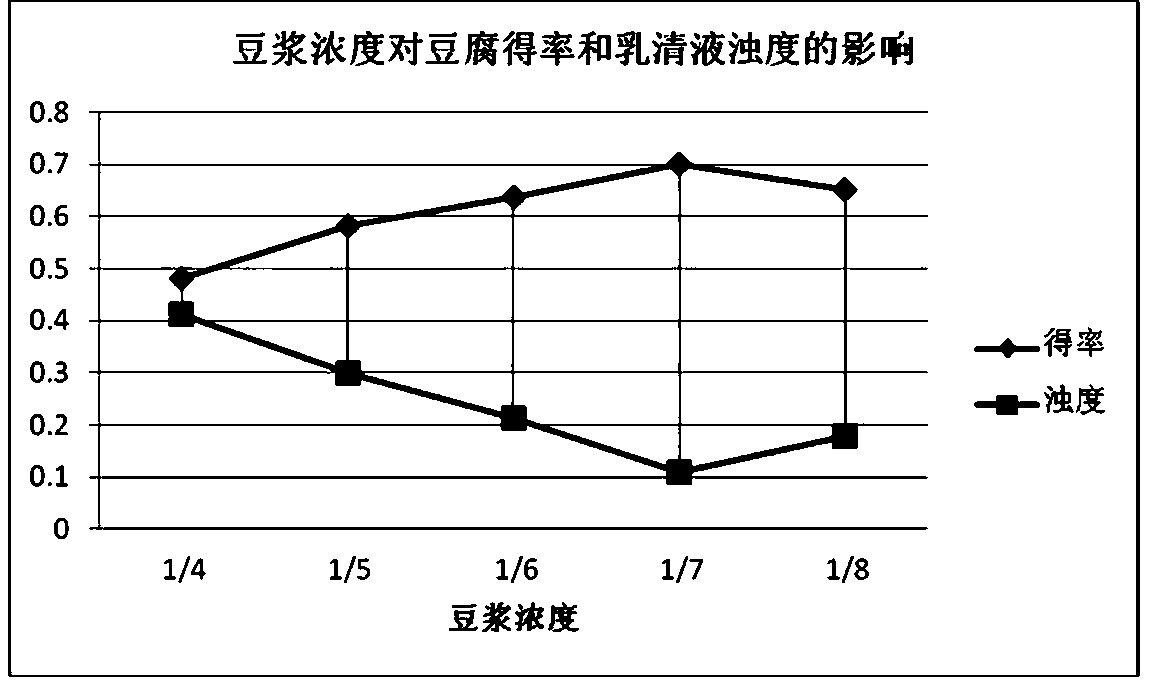

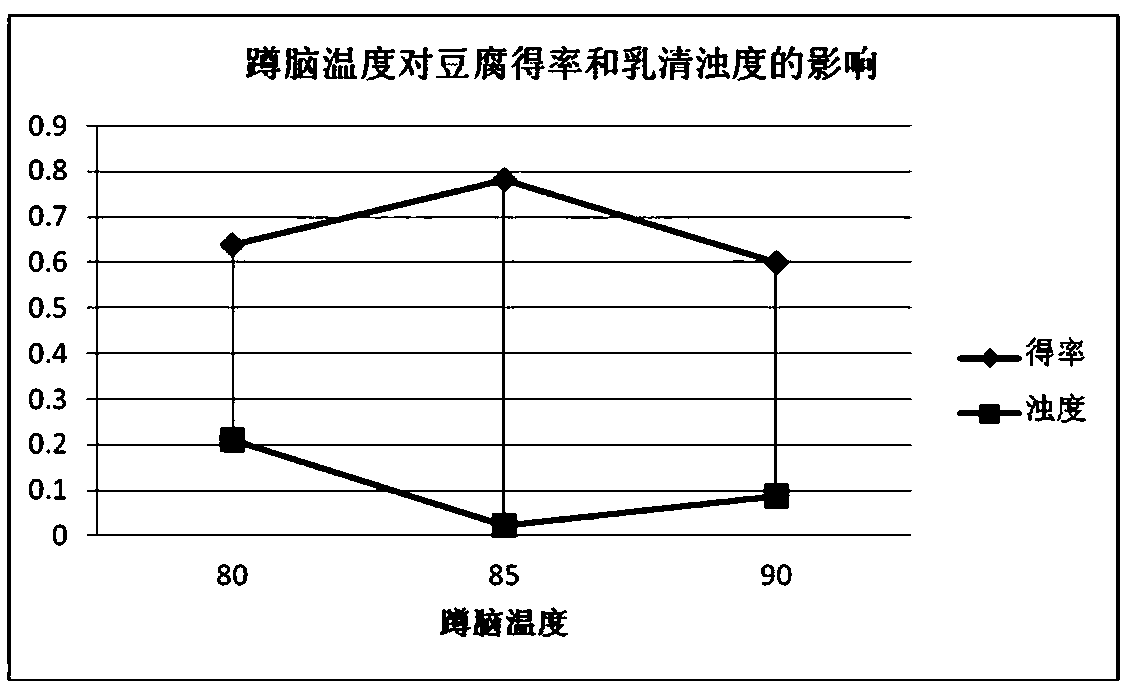

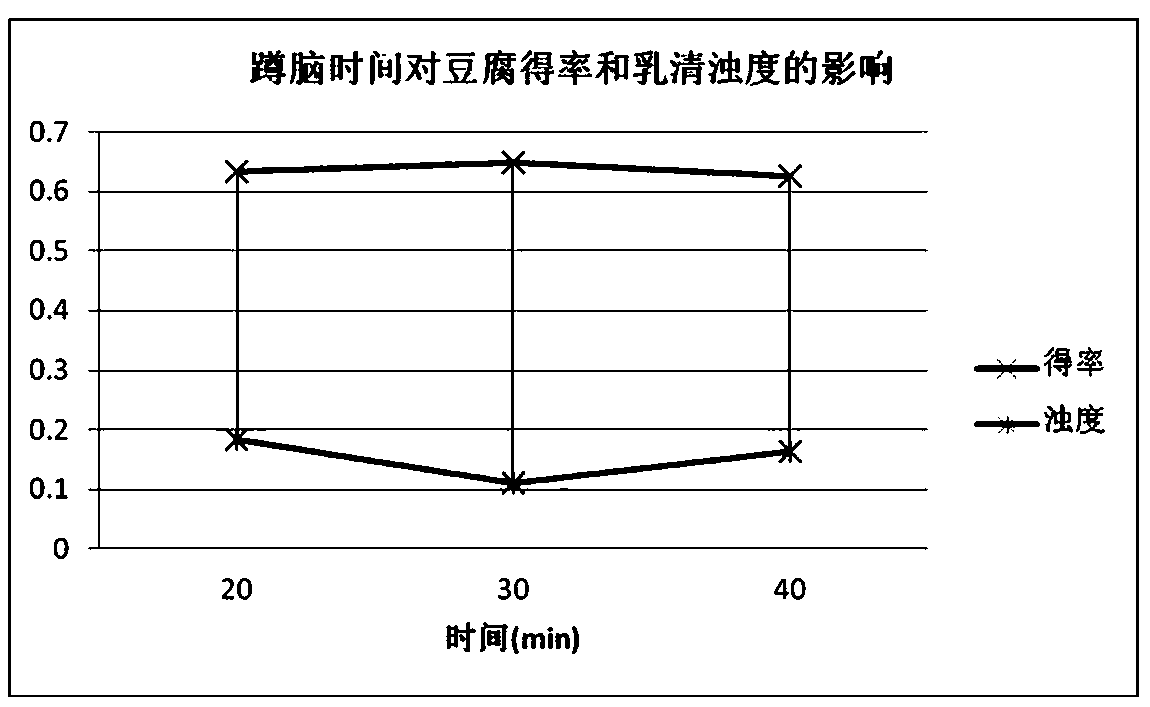

[0060] On the basis of Example 1, the inventors carried out an orthogonal experimental design on single factors such as the concentration of soy milk that affects the yield of tofu, the quality of tofu, the amount of whey powder fermented liquid, and the temperature of the brain, in order to explore the best tofu preparation. craft. A brief introduction is as follows.

[0061] First designed the L 9 (3) 3 The orthogonal test table is as follows:

[0062] .

[0063] The optimal process conditions of milk tofu are determined by the yield of tofu and its sensory evaluation. The results are shown in the following table:

[0064]

[0065] From the analysis of the above table, it can be seen that the order of the influence of the three factors on the yield of tofu is brain temperature, concentration of soybean milk and the amount of whey added. The optimal factor levels are: the concentration of soybean milk is 1:8, the amount of whey added is 100mL, and the brain temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com