Soybean milk bean curd and preparation method thereof

A technology for soybean milk and tofu, applied in the field of food processing, can solve the problems of single taste, low absorption and utilization rate of nutrients, and difficulty in meeting nutritional needs, and achieve the effects of high nutritional value, improved quality and grade, and rich varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

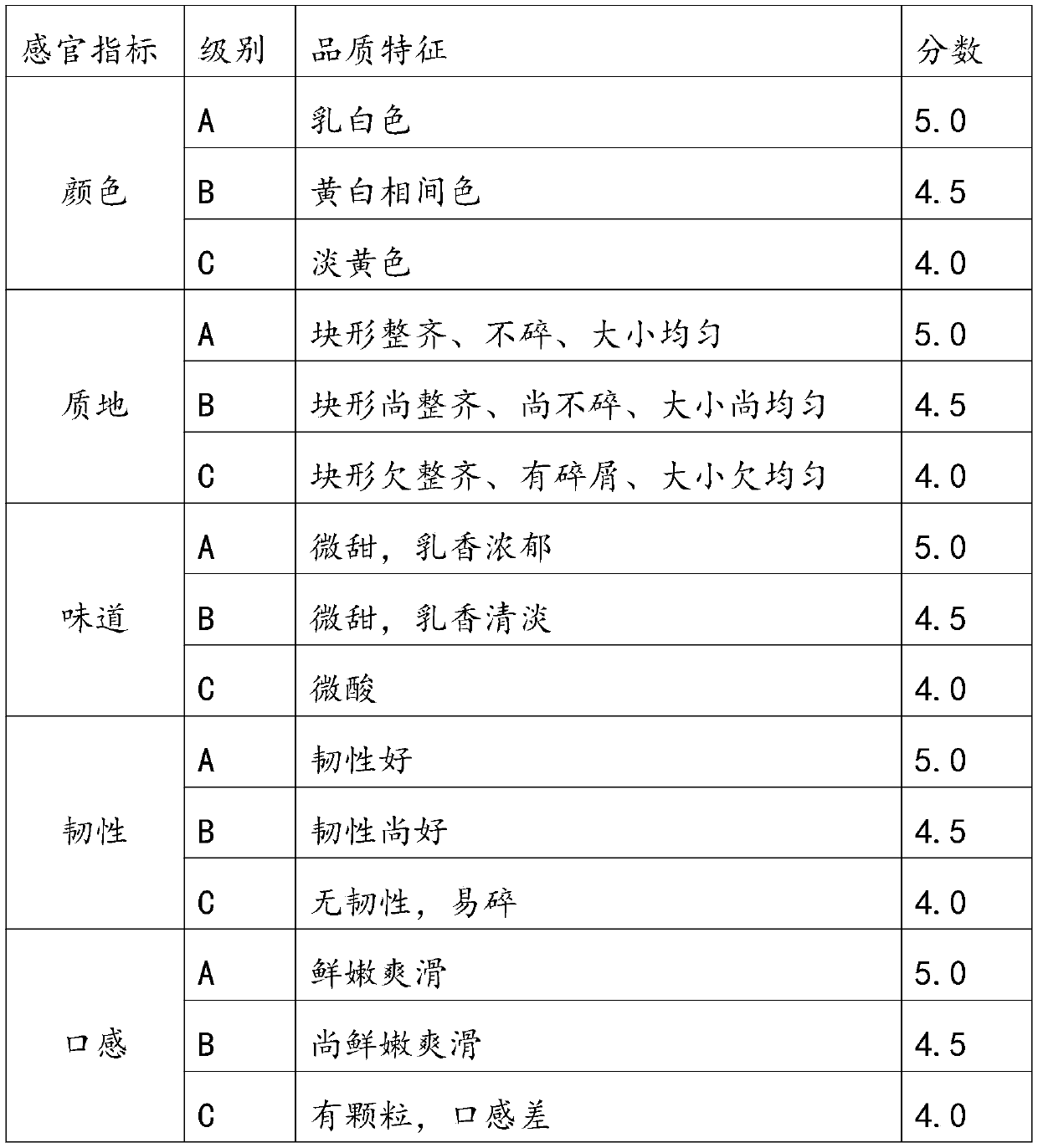

Embodiment 1

[0034] Soak soybeans in water at 20°C for 12 hours, control the mass ratio of soybeans and water to 1:6 for beating, and separate solid and liquid after beating to obtain soybean milk; mix soybean milk and milk, control the mass ratio of milk and soybeans to 0.5:1 , and heated to boiling to obtain a mixed slurry; add the aqueous solution of the physalis to the mixed slurry for segmental slurry, control the mass ratio of the aqueous solution of the physalis and soybeans to be 1:1 each time the slurry is placed, and the segmental slurry is stirred It is carried out under certain conditions, and the pulp is divided into three stages, and the time for each pulping is 2 minutes; after the pulping is completed, it is first boiled at a temperature of 80°C until it boils slightly, and kept for 2 minutes, and then it is left to stand for 20 minutes to precipitate the juice, and tofu is obtained. Brain; Put the bean curd brain into a mold, press and shape, and obtain the soybean milk tof...

Embodiment 2

[0037] Soak soybeans in water at 25°C for 6 hours, control the mass ratio of soybeans and water to 1:10 for beating, and separate solid and liquid after beating to obtain soybean milk; mix soybean milk and milk, control the mass ratio of milk and soybeans to 1.5:1 , and heated to boiling to obtain a mixed slurry; add the aqueous solution of Physalis obtained in Example 1 to the mixed slurry and point slurry in stages, and the aqueous solution of Physalis is mixed by Physalis and water in a mass ratio of 1:0.5, and control each point When pulping, the mass ratio of the aqueous solution of acid pulp to soybeans is 2:1, and the segmented pulping is carried out under the condition of stirring, and is carried out in 5 stages, and the time for each pulping is 8 minutes; after the pulping is completed, the temperature of 100 ° C Boil until slightly boiled, and keep it for 1 minute, and then stand still for 30 minutes to precipitate the juice to obtain tofu nao; put the tofu nao into a...

Embodiment 3

[0040] Soak soybeans in water at 22°C for 9 hours, control the mass ratio of soybeans and water to 1:8 for beating, and separate solid and liquid after beating to obtain soybean milk; mix soybean milk and milk, control the mass ratio of milk and soybeans to 1:1 , and heated to boiling to obtain a mixed slurry; add the aqueous solution of Physalis obtained in Example 2 to the mixed slurry and point slurry in stages, and the aqueous solution of Physalis is mixed by Physalis and water in a mass ratio of 1:1.5, and each point is controlled. When pulping, the mass ratio of the aqueous solution of Physicum pulp to soybeans is 1.5:1, and the segmental pulping is carried out under stirring conditions, and is carried out in 4 stages, and the time for each pulping is 5 minutes; after the pulping is completed, the temperature of 90 ° C Boil until slightly boiled, and keep it for 1.5 minutes, and then stand still for 25 minutes to precipitate the juice to obtain tofu nao; put the tofu nao ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com