A kind of method for preparing silk fibroin-xanthan gum hydrogel support

A technology of xanthan gum and silk fibroin, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, prostheses, etc., can solve the problems of easy solubility in water, easy damage, poor water resistance and mechanical properties, and achieve low cost Low cost, large amount of embedding, and the effect of improving drug efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

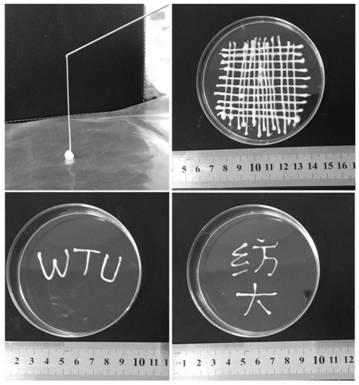

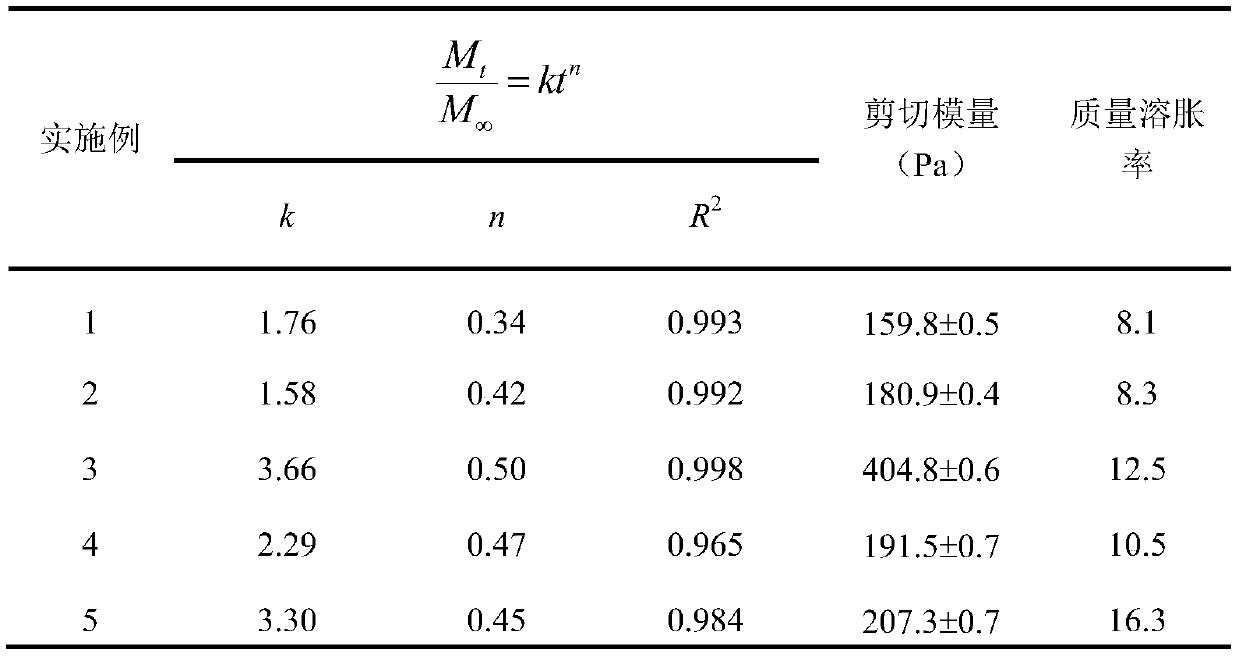

[0030] Disperse 0.125g of silk fibroin powder in 25mL of NaOH aqueous solution with pH=14, stir it magnetically for 2 hours to prepare a silk fibroin suspension with a concentration of 0.5% w / v, add 1.25g of xanthan gum to the above concentration of 0.5% In the w / v silk fibroin suspension, continue magnetic stirring for 12 hours to obtain a uniformly mixed silk fibroin-xanthan gum sol, add 10 mL of 187.5 mg / mL sodium trimetaphosphate to the above silk fibroin-xanthan gum sol , stirred rapidly for 5 minutes to obtain a pre-gel solution, and after cross-linking the pre-gel solution for 4 hours at a temperature of 37 ° C, 10 mL of 12 mg / mL 1-(3-dimethylaminopropyl)-3-ethylcarbodi A mixed solution of imine hydrochloride and 18 mg / mL N-hydroxysuccinimide was added to the above-mentioned silk fibroin-xanthan gum hydrogel cross-linked by sodium trimetaphosphate, and the cross-linking reaction was carried out at 37 °C for 12 hours to obtain Silk fibroin-xanthan gum hydrogel scaffold, ...

Embodiment 2

[0032] Disperse 1.25g of silk fibroin powder in 25mL of NaOH aqueous solution with pH=12, stir it magnetically for 2h and prepare a silk fibroin suspension with a concentration of 5% w / v, add 0.125g of xanthan gum to the above concentration of 5% In the silk fibroin suspension of w / v, continue magnetic stirring for 12h to obtain a uniformly mixed silk fibroin-xanthan gum sol, add 10mL of 75mg / mL sodium trimetaphosphate into the above-mentioned silk fibroin-xanthan gum sol, Stir rapidly for 5 minutes to obtain a pre-gel solution. After cross-linking the pre-gel solution at 37°C for 30 minutes, add 10 mL of 12 mg / mL 1-(3-dimethylaminopropyl)-3-ethylcarbodiethylene A mixed solution of amine hydrochloride and 18 mg / mL N-hydroxysuccinimide was added to the above-mentioned silk fibroin-xanthan gum hydrogel cross-linked by sodium trimetaphosphate, and the cross-linking reaction was carried out at 37 ° C for 48 hours to obtain silk The silk fibroin-xanthan gum hydrogel scaffold, the r...

Embodiment 3

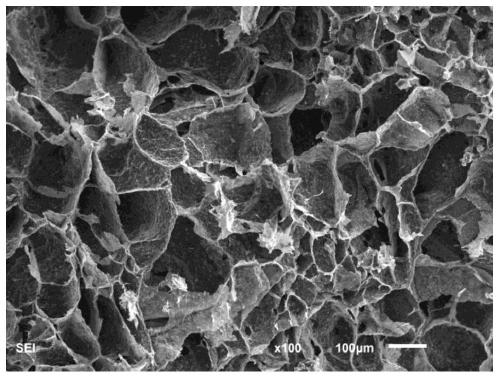

[0034] Disperse 0.75g silk fibroin powder in 25mL NaOH aqueous solution with pH=13, stir magnetically for 2h and prepare a silk fibroin suspension with a concentration of 3% w / v, add 0.75g xanthan gum to the above concentration of 3% In the silk fibroin suspension of w / v, continue magnetic stirring for 12h to obtain a uniformly mixed silk fibroin-xanthan gum sol, add 10mL 225mg / mL sodium trimetaphosphate into the above-mentioned silk fibroin-xanthan gum sol, Stir rapidly for 5 minutes to obtain a pre-gel solution. After cross-linking the pre-gel solution at 37°C for 2 hours, add 10 mL of 12 mg / mL 1-(3-dimethylaminopropyl)-3-ethylcarbodiethylene A mixed solution of amine hydrochloride and 18 mg / mL N-hydroxysuccinimide was added to the above-mentioned silk fibroin-xanthan gum hydrogel cross-linked by sodium trimetaphosphate, and the cross-linking reaction was carried out at 37 ° C for 24 hours to obtain silk The silk fibroin-xanthan gum hydrogel scaffold, the rheological behavio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap