Preparation process of honeycomb ceramic plate loaded TiO2-NCP immobilized photocatalyst

A technology of honeycomb ceramic plates and photocatalysts, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to achieve easy recycling and reuse, stable performance, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

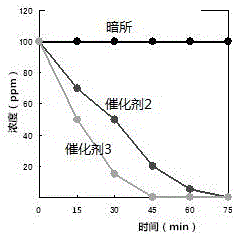

Examples

Embodiment 1

[0035] The honeycomb ceramic plate loaded with TiO 2 -The preparation technology of NCP immobilized photocatalyst comprises the following steps:

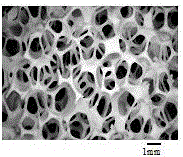

[0036] 1) Preparation of honeycomb ceramic plate:

[0037] Silicon oxide, aluminum oxide, magnesium oxide, iron oxide, titanium dioxide, K 2 O and Na 2 O and CaO are wet-milled in a ball mill to less than 320 mesh powder, silicon oxide, aluminum oxide, magnesium oxide, iron oxide, titanium dioxide, K 2 O and Na 2 The mass percentage of O and CaO components is 39% of silicon oxide, 52% of aluminum oxide, 6% of magnesium oxide, 0.8% of iron oxide, 1.0% of titanium dioxide, K 2 O and Na 2 O and CaO 1.2%, the powder after ball milling becomes mud block after pressure filtration and vacuum refining, and the green body is synthesized in a downdraft kiln to become cordierite material; then the synthesized cordierite is finely ground again to the required Granularity is required; then the finely ground cordierite powder is added to th...

Embodiment 2

[0049] The honeycomb ceramic plate loaded with TiO 2 -The preparation technology of NCP immobilized photocatalyst comprises the following steps:

[0050] 1) Preparation of honeycomb ceramic plate:

[0051] Silicon oxide, aluminum oxide, magnesium oxide, iron oxide, titanium dioxide, K 2 O and Na 2 O and CaO are wet-milled in a ball mill to less than 320 mesh powder, silicon oxide, aluminum oxide, magnesium oxide, iron oxide, titanium dioxide, K 2 O and Na 2 The mass percentages of O and CaO components are silicon oxide 44%, aluminum oxide 47%, magnesium oxide 5%, iron oxide 0.5%, titanium dioxide 1.9%, K 2 O and Na 2 O and CaO 1.6%, the powder after ball milling becomes mud block after pressure filtration and vacuum refining, and the green body is synthesized in a downdraft kiln to become cordierite material; then the synthesized cordierite is finely ground again to the required Granularity is required; then the finely ground cordierite powder is added to the binder with...

Embodiment 3

[0063] The honeycomb ceramic plate loaded with TiO 2 -The preparation technology of NCP immobilized photocatalyst comprises the following steps:

[0064] 1) Preparation of honeycomb ceramic plate:

[0065] Silicon oxide, aluminum oxide, magnesium oxide, iron oxide, titanium dioxide, K 2 O and Na 2 O and CaO are wet-milled in a ball mill to less than 320 mesh powder, silicon oxide, aluminum oxide, magnesium oxide, iron oxide, titanium dioxide, K 2 O and Na 2 The mass percentage of each component of O and CaO is 42% of silicon oxide, 50% of aluminum oxide, 5% of magnesium oxide, 0.5% of iron oxide, 1% of titanium dioxide, K 2 O and Na 2 O and CaO 1.5%, the powder after ball milling becomes mud block after pressure filtration and vacuum refining, and the green body is synthesized in a downdraft kiln to become cordierite material; then the synthesized cordierite is finely ground again to the required Granularity is required; then the finely ground cordierite powder is added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com