Cleanser for colored plastic processing equipment and preparation method for same

A technology for processing equipment and cleaning agents, which is applied in the field of composite polymer materials and its processing, can solve the problems of endangering the health of employees, unsatisfactory effects, and reducing the service life of equipment, so as to reduce the phenomenon of broken bars and powder floating Phenomenon, the effect of accelerating the discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

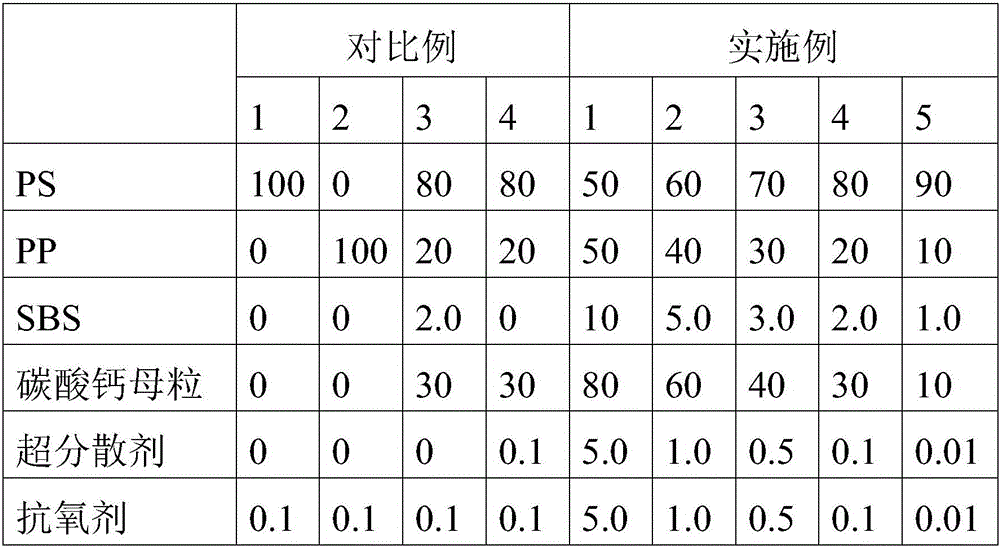

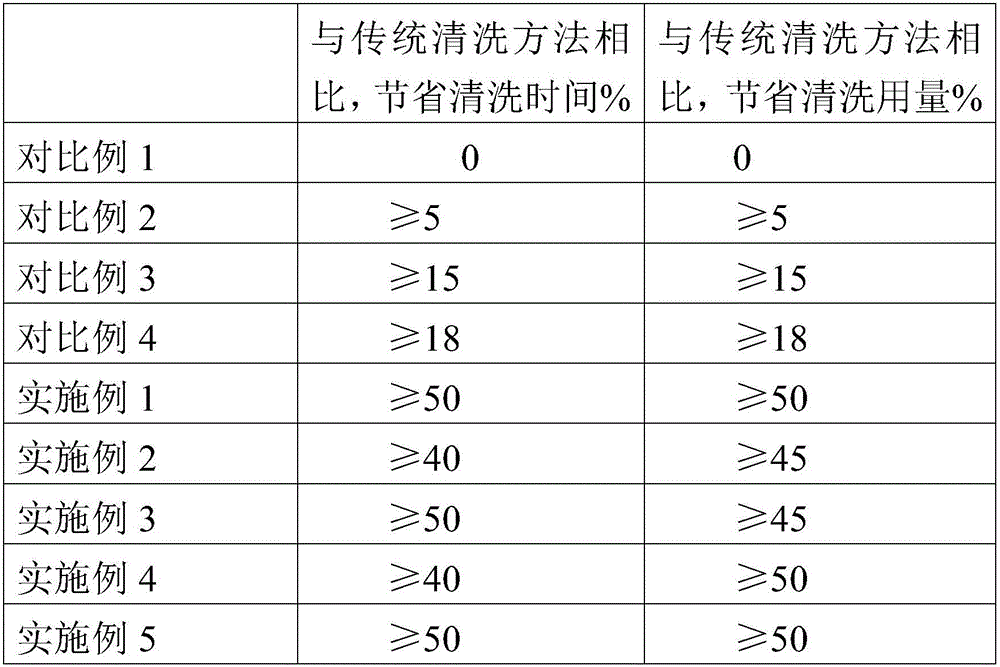

Embodiment 1

[0034] Weigh 50 parts of polypropylene resin, 50 parts of polystyrene resin, 10 parts of styrene-butadiene-styrene block copolymer, 80 parts of calcium carbonate masterbatch, 5 parts of hyperdispersant and 5 parts of antioxidant, Put the weighed raw materials of each component into the mixer and mix them thoroughly for 5 minutes to obtain a premix; put the obtained premix into a twin-screw extruder for melt extrusion and strand granulation to obtain colored plastic processing Cleaning agent for equipment, wherein the process parameters of the twin-screw extruder are: the temperature of the first zone is 160°C, the temperature of the second zone is 180°C, the temperature of the third zone is 180°C, the temperature of the fourth zone is 180°C, and the temperature of the fifth zone is 180°C, the temperature of the sixth zone is 180°C, the temperature of the seventh zone is 180°C, the temperature of the eighth zone is 180°C, the temperature of the ninth zone is 180°C, the temperatu...

Embodiment 2

[0036] Weigh 40 parts of polypropylene resin, 60 parts of polystyrene resin, 5 parts of styrene-butadiene-styrene block copolymer, 60 parts of calcium carbonate masterbatch, 1 part of hyperdispersant and 1 part of antioxidant, Put the weighed raw materials of each component into the mixer and mix them thoroughly for 10 minutes to obtain a premix; put the obtained premix into a twin-screw extruder for melt extrusion and strand granulation to obtain colored plastic processing Cleaning agent for equipment, wherein the process parameters of the twin-screw extruder are: the temperature of the first zone is 170°C, the temperature of the second zone is 190°C, the temperature of the third zone is 190°C, the temperature of the fourth zone is 190°C, and the temperature of the fifth zone is 190°C, the temperature of the sixth zone is 190°C, the temperature of the seventh zone is 190°C, the temperature of the eighth zone is 190°C, the temperature of the ninth zone is 190°C, the temperature...

Embodiment 3

[0038] Weigh 30 parts of polypropylene resin, 70 parts of polystyrene resin, 3 parts of styrene-butadiene-styrene block copolymer, 40 parts of calcium carbonate masterbatch, 0.5 part of hyperdispersant and 0.5 part of antioxidant, Put the weighed raw materials of each component into the mixer and mix them thoroughly for 15 minutes to obtain a premix; put the obtained premix into a twin-screw extruder for melt extrusion and strand granulation to obtain colored plastic processing Cleaning agent for equipment, wherein the process parameters of the twin-screw extruder are: the temperature of the first zone is 180°C, the temperature of the second zone is 200°C, the temperature of the third zone is 200°C, the temperature of the fourth zone is 200°C, and the temperature of the fifth zone is 200°C, the temperature of the sixth zone is 200°C, the temperature of the seventh zone is 200°C, the temperature of the eighth zone is 200°C, the temperature of the ninth zone is 200°C, the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com