Anti-corona material for end parts of coil bars of motors and application method of anti-corona material

An application method and motor wire technology, applied in epoxy resin coatings, coatings and other directions, can solve the problem of unstable anti-corona effect, and achieve the effect of good anti-corona effect, good electrical performance and stable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

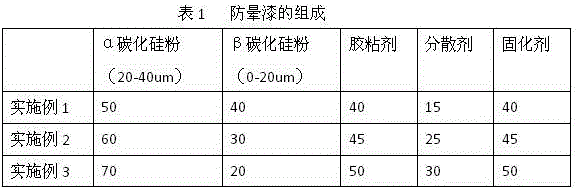

[0030] Mix according to the proportioning ratio in Table 1 to obtain the anti-halation paint at the end of the motor wire rod.

[0031]

[0032] After the raw materials mentioned in the above table are stirred evenly, the anti-halation paint is made, and then the experimental platform for dipping and drying is built, and the anti-halation paint is evenly impregnated on the non-alkali glass cloth and dried to make the anti-halation tape 1, 2, 3. The thickness of the anti-halation belt is 1.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com