Equipment for improving particle distribution of in-situ particle reinforced aluminum matrix composite and application

A particle-reinforced aluminum and composite material technology, applied in the field of materials, can solve problems such as a large number of particles and agglomeration, and achieve the effects of low cost, simple equipment and large cumulative deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In situ self-generated 5wt.%TiB obtained by casting 2 / 7050Al composite material, a large amount of TiB in the as-cast structure 2 Particles agglomerate at grain boundaries. In situ self-generated 5wt.%TiB obtained by casting 2 / 7050Al composite material was homogenized at 465°C for 24 hours, and then subjected to two-pass orthogonal lamination extrusion at 450°C. After extrusion, the in-situ particle agglomeration at the grain boundary of the matrix aluminum alloy in the composite Body is broken up, TiB 2 The particles are uniformly distributed in the matrix alloy. 5wt.%TiB after two passes of orthogonal extrusion 2 The / 7050Al composite was solid-soluted at 470°C for 70min and aged at 120°C for 20h, then its mechanical properties were characterized, and it had a plasticity of more than 10%, indicating that the in-situ 5wt.%TiB 2 The particle aggregates in the matrix structure of / 7050Al composites were completely broken up.

Embodiment 2

[0029] In situ self-generated 5wt.%TiB obtained by casting 2 / 2024Al composite material, there is a large amount of TiB in the as-cast structure 2 Particles agglomerate at grain boundaries. In situ self-generated 5wt.%TiB obtained by casting 2 / 2024Al composites were homogenized at 490°C for 48 hours, and then four passes of orthogonal lamination extrusion was carried out at 450°C. Body is broken up, TiB 2 The particles are evenly distributed in the matrix alloy, and 5wt.% TiB is self-generated in situ 2 The uniformity of particle distribution within the / 2024Al composite is improved.

Embodiment 3

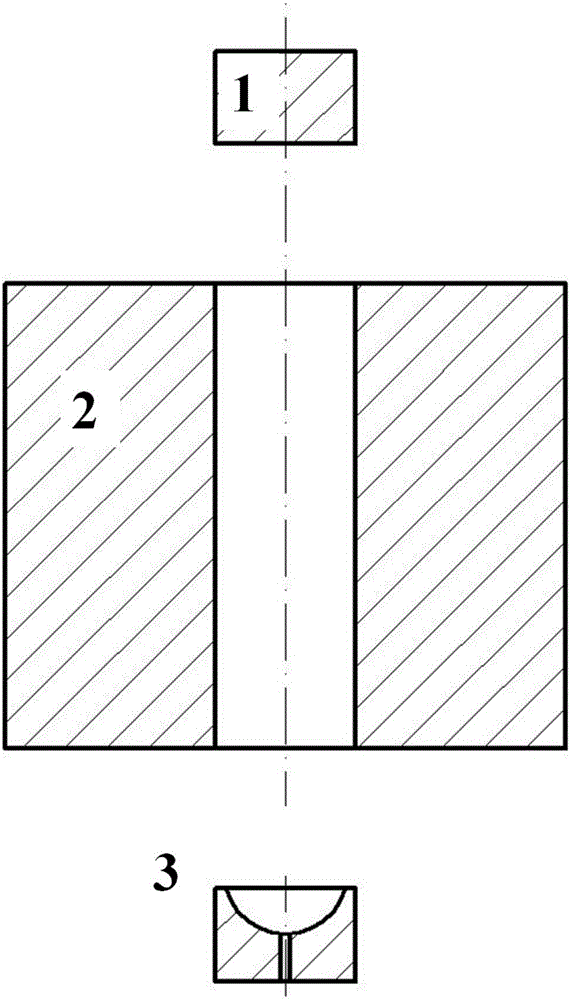

[0031] Devices for improving particle distribution of in-situ particle-reinforced aluminum matrix composites with structures such as figure 1As shown, it includes an upper pressure head 1, a mold cylinder 2 and a mold head 3. The middle part of the mold cylinder 2 is provided with a through hole with a square structure in cross section, and the side length is d. The upper pressure head 1 and the mold head 3 are connected to the through hole. When in use, the composite material is placed in the through hole, and the upper pressure head and the die head are respectively placed on the upper and lower surfaces of the composite material and pressed tightly. The die head 3 is also provided with a pit, and the bottom of the pit is provided with a through hole communicating with the bottom.

[0032] To improve the application of in-situ particle-reinforced aluminum matrix composite particle distribution equipment, the following steps are taken:

[0033] (1) The particle-reinforced al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com