A directional corrosion film component and its use method

A technology for corrosion film and components, applied in the field of directional corrosion film components, can solve the problems of reduced service life, easy corrosion of the cover, corrosion of the box, etc., and achieves the effect of improving the firmness of adhesion and increasing the surface area of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

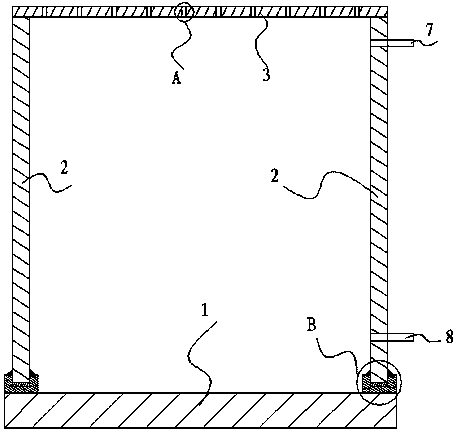

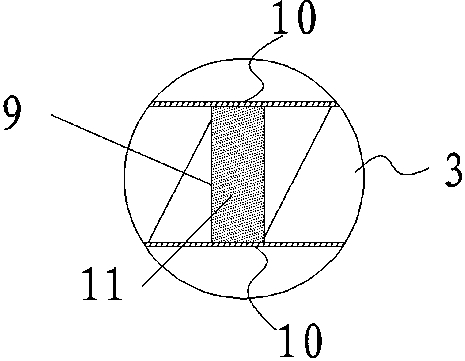

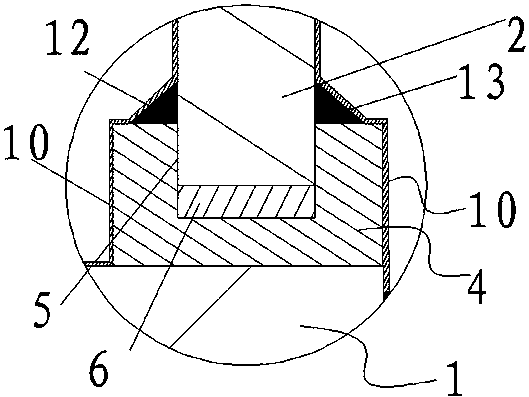

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0017] Such as Figure 1-Figure 6 As shown, a directional corrosion film assembly, the directional corrosion film assembly includes a composite film body, the composite film body forms a corrosion bag for accommodating the water tank cover 3, the corrosion bag is provided with an opening, and the opening is A sealing strip 17 is provided; the composite membrane body includes an outer membrane body 14 and an inner membrane body 15 compounded with the outer membrane body, the surface of the inner membrane body 15 is provided with a bubble body 19, and the inside of the bubble body 19 There is hydrochloric acid solution, and a one-way suction valve 18 is also...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com