Target material assembly and processing method thereof

A processing method and target material technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as inability to effectively improve the quality of coating products, shedding, etc., to increase the adhesion surface area, reduce shedding, and apply wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment provides a processing method for a target assembly, the processing method comprising the following steps:

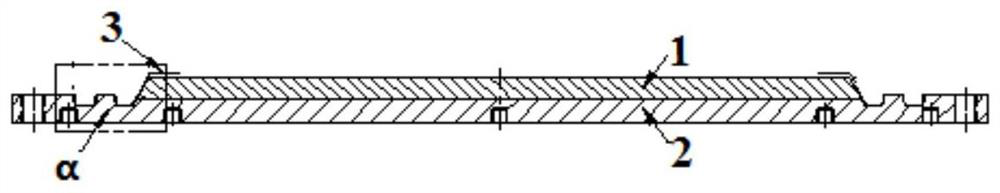

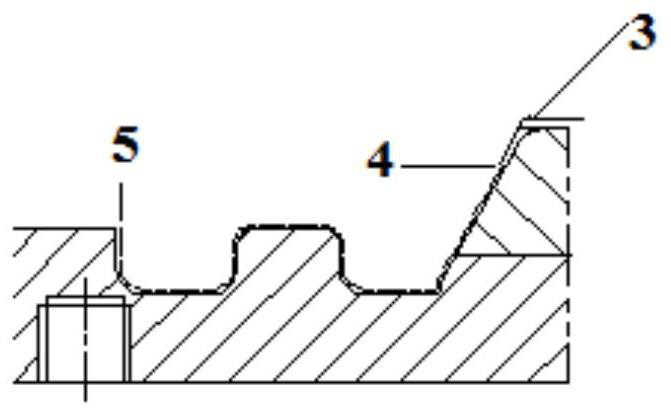

[0057] (1) The titanium target 1 and the aluminum alloy back plate 2 are welded together and then machined. The target 1 is obtained by cutting and thermoplastically deforming the titanium ingot. The machining includes: machining the side of the target 1 to form Chamfering, so that the size of the sputtering surface of the target 1 is smaller than the size of the welding surface of the target 1, the side of the target 1 after the machining is an inclined plane, and the angle between the welding surface of the target 1 is 15 degrees, and the primary target is obtained material components;

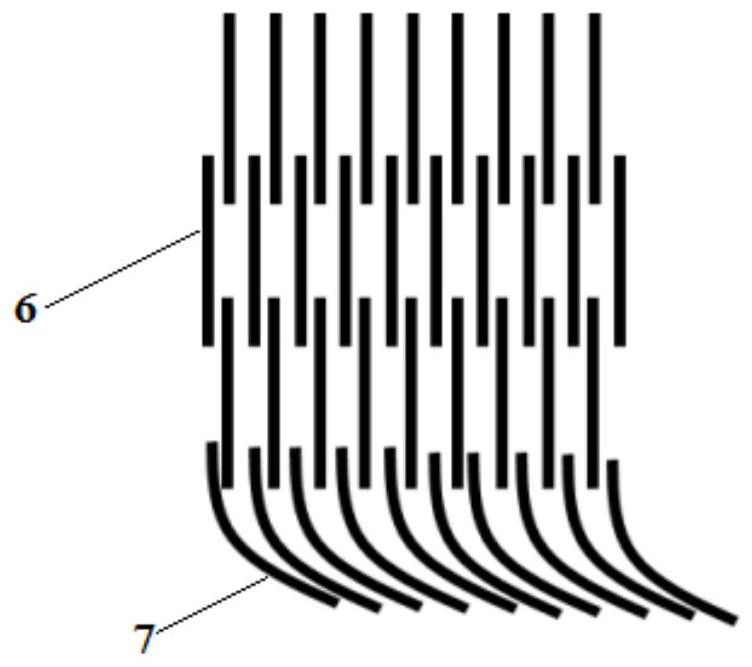

[0058] (2) Carry out knurling treatment to the edge of the sputtering surface of the target 1 and part of the side area of the target 1 in the primary target assembly obtained in step (1), and the knurled area of the edge of the sputtering surface of the targ...

Embodiment 2

[0064] This embodiment provides a processing method for a target assembly, the processing method comprising the following steps:

[0065] (1) The titanium target 1 and the copper alloy back plate 2 are welded together and then machined. The target 1 is obtained by cutting and thermoplastically deforming the titanium ingot. The machining includes: machining the side of the target 1 to form Chamfering, so that the size of the sputtering surface of the target 1 is smaller than the size of the welding surface of the target 1, the side of the target 1 after machining is an inclined plane, and the angle between the welding surface of the target 1 is 35 degrees, and the primary target is obtained material components;

[0066] (2) Carry out knurling treatment to the edge of the sputtering surface of the target 1 and part of the side area of the target 1 in the primary target assembly obtained in step (1), and the knurled area of the edge of the sputtering surface of the target 1 ...

Embodiment 3

[0070] This embodiment provides a processing method for a target assembly, the processing method comprising the following steps:

[0071] (1) The aluminum target 1 and the aluminum alloy back plate 2 are welded together and then machined. The target 1 is obtained by cutting and thermoplastically deforming an aluminum ingot. The machining includes: machining the side of the target 1 to form Chamfering, so that the size of the sputtering surface of the target 1 is smaller than the size of the welding surface of the target 1, the side of the target 1 after machining is an inclined plane, and the angle with the welding surface of the target 1 is 45 degrees, and the primary target is obtained material components;

[0072] (2) Carry out knurling treatment to the edge of the sputtering surface of the target 1 and part of the side area of the target 1 in the primary target assembly obtained in step (1), and the knurled area of the edge of the sputtering surface of the target 1 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com