Aluminum melting holding furnace for gas crucible

A technology for holding furnaces and crucibles, which is applied in the direction of crucible furnaces, furnaces, furnace materials, etc., which can solve problems such as high temperature, waste of energy, and impact on the environment, and achieve the effects of reducing heat loss, saving energy, and improving the ambient temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

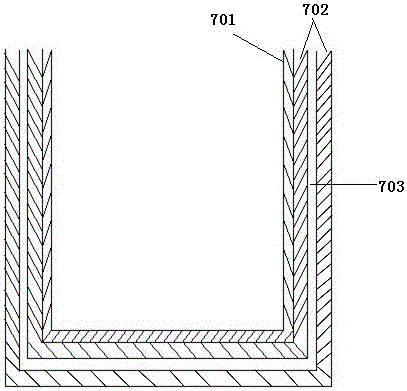

[0019] Embodiment 1: The thickness of the rock wool board 701 is 10mm, the thickness of the steel mesh sandwich panel 702 is 10mm, and the thickness of the hollow layer composed of two steel mesh sandwich panels 702 is 10mm.

Embodiment 2

[0020] Embodiment 2: The thickness of the rock wool board 701 is 100mm, the thickness of the steel mesh sandwich panel 702 is 50mm, and the thickness of the hollow layer composed of two steel mesh sandwich panels 702 is 50mm.

Embodiment 3

[0021] Embodiment 3: The thickness of the rock wool board 701 is 50mm, the thickness of the steel mesh sandwich panel 702 is 30mm, and the thickness of the hollow layer composed of two steel mesh sandwich panels 702 is 30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com