System for carrying out dynamic triaxial test by using high frequency circulating water pressure

A technology of dynamic triaxial test and circulating water pressure, applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc., can solve problems such as difficult to be widely used, strong destructiveness, and high test cost. To achieve the effect of enhancing comprehensiveness and practicability, reducing destructive effects, and protecting self-safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

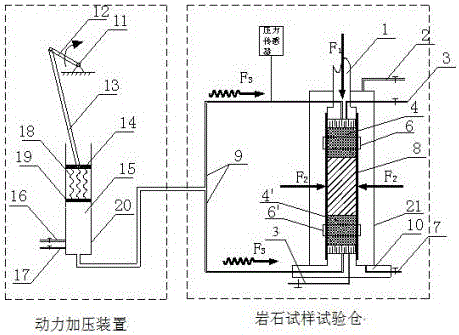

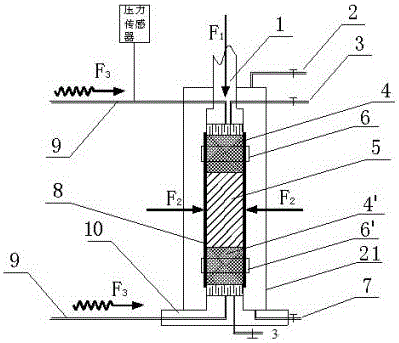

[0024] In order to further describe the present invention, the system for rock dynamic triaxial test using high-frequency circulating water pressure of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

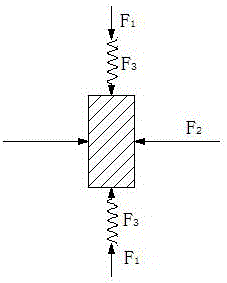

[0025] Depend on figure 1 As shown, the present invention utilizes high-frequency circulating water pressure to carry out the system structure connection diagram of rock dynamic triaxial test and finds out that there are three parts of load when rock sample 5 carries out dynamic triaxial test among the present invention, respectively is confining pressure F 2 , static axial pressure F 1 and hydrodynamic pressure F 3 , they are respectively provided by the sample chamber body 21, the pressure head 1 and the dynamic hydraulic pressure pipe 9. The outer ends of the upper pressure-bearing part 4 and the lower pressure-bearing part 4' are subjected to static axial pressure F 1 and hydrodynamic pressure F ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com