Quantitative detection method for primary silicon phases in hypereutectic aluminum-silicon alloy

A technology of aluminum-silicon alloy and detection method, which is applied in the direction of measuring device, instrument, particle size analysis, etc., can solve the problems of heavy image processing workload and complex image processing process, and achieves the effect of strong versatility and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The quantitative detection of the primary silicon phase was carried out on the B390 Al-Si alloy as-cast tensile test bar whose nominal chemical composition is shown in Table 1.

[0055] Table 1 Nominal chemical composition of B390 Al-Si alloy (wt.%)

[0056] Si Fe Cu mn Mg Ni Zn sn Al 16.0~18.0 0.9 4.0~5.0 0.50 0.50~0.65 0.30 1.5 0.30 Bal.

[0057] Taking the area of the primary silicon phase as an example, the quantitative detection method is as follows:

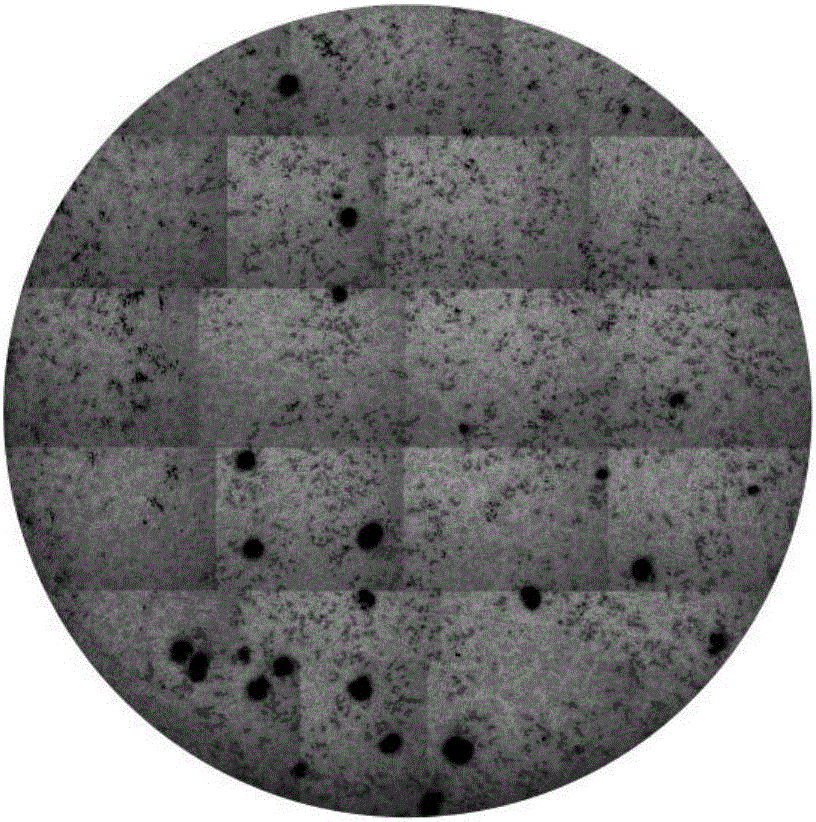

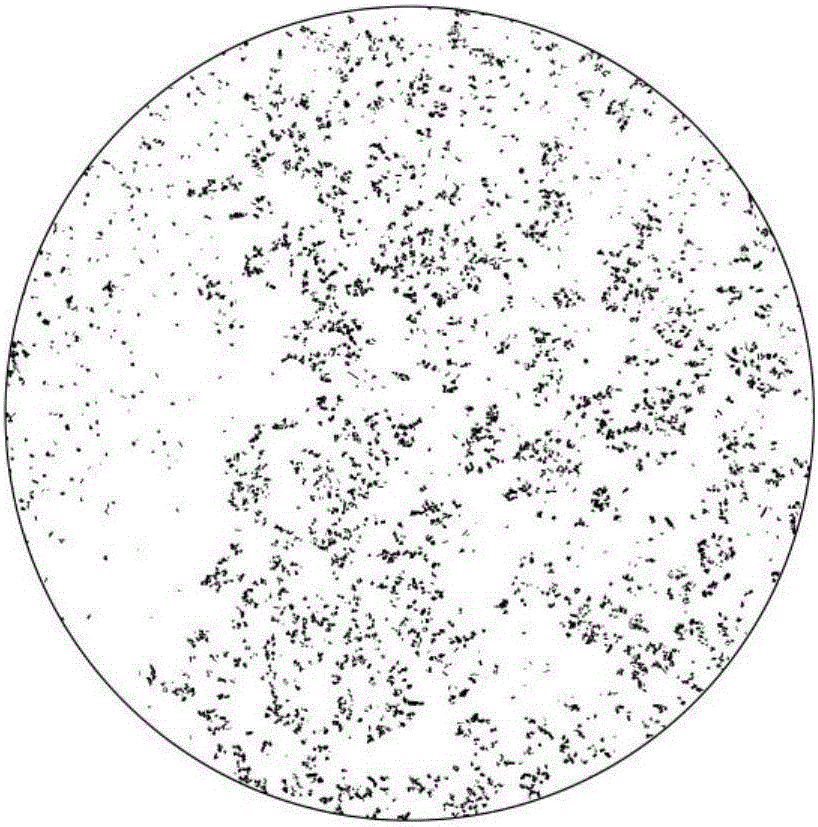

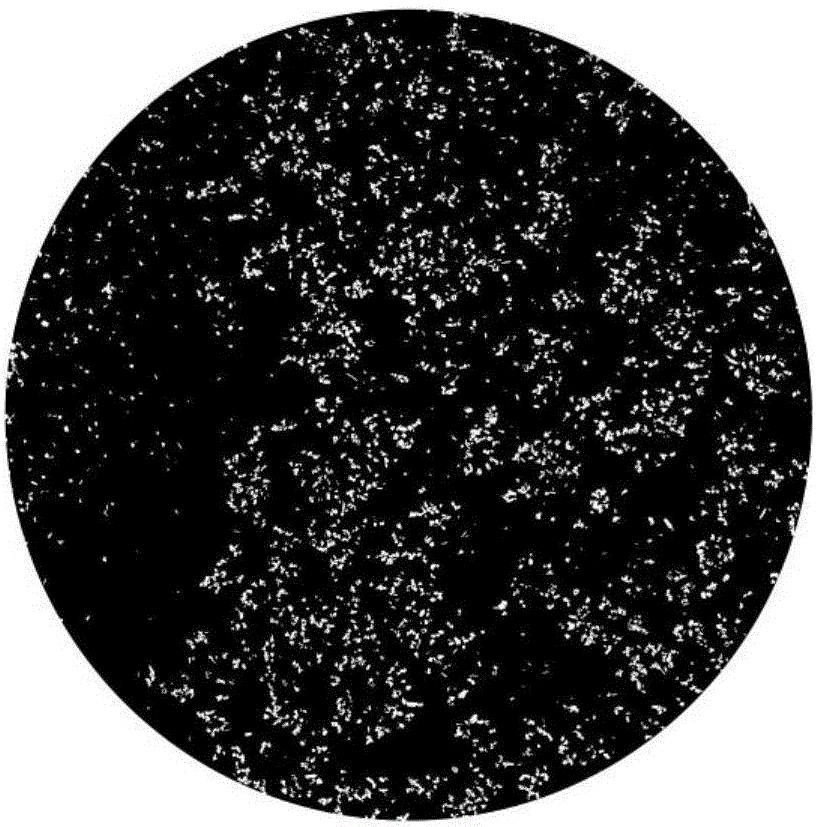

[0058] (1) Collect all the images: intercept a B390 aluminum-silicon alloy sample with a length of about 5mm near the fracture of the tensile test rod, and the section to be inspected is about 5mm from the fracture. , 1500#, and 4000# water-resistant sandpaper are ground and polished, and the camera attached to the optical microscope is used to continuously collect images of the entire polished surface without omission and overlap, and the scale is superimposed with the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com