Insulator flashover test temperature control device and use method

A technology of flashover test and temperature control device, which is applied in the direction of measuring device, dielectric strength test, instrument, etc., and can solve the problems affecting the moisture condition of the surface of insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

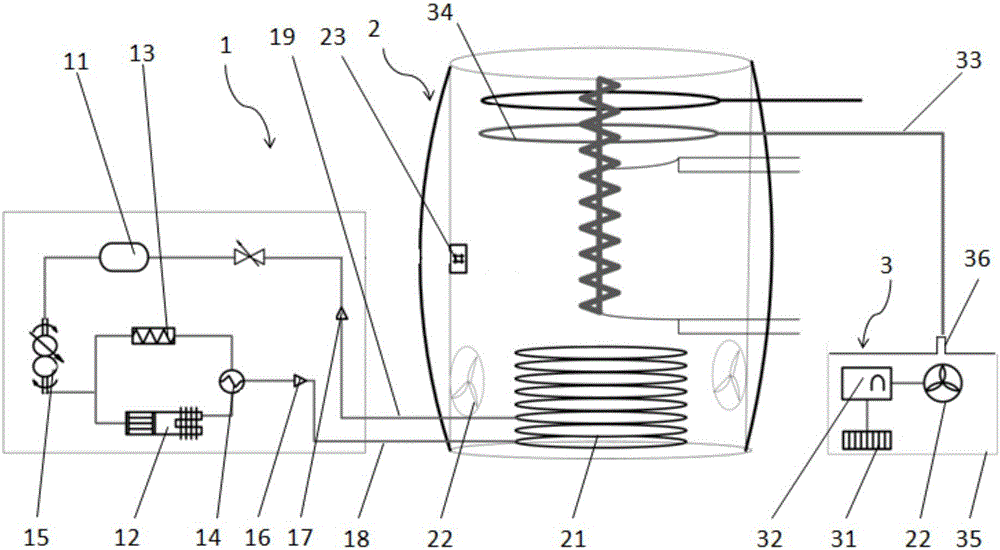

[0038] In order to explain the method of use provided by the present invention in more detail, it is specified by setting the ambient temperature required for the insulator test to be 8°C:

[0039] Step 1: Set the set temperature of the coil to -25°C. After running for 30 minutes, the temperature of the heat transfer oil in the coil is about -25±0.3°C; The air is blown upwards, and the fogging humidifier is turned on at the same time to keep the humidity in the haze tank constant, reduce the variables, and measure the temperature in the haze tank through the temperature sensor, and the running time is about 5 minutes;

[0040] Step 2: Turn on the fan around the coil to further cool down the temperature inside the mist tank. The mist humidifier is still turned on. The operating time is about 2 minutes, and the ambient temperature can reach 8°C

[0041] If the temperature required for the test is between 12 and 20°C, step 2 can be omitted to directly meet the test requirements. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com