Production technology of aluminium-plastic panel

A production process and technology of aluminum-plastic panels, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems of slow production speed, complex production methods and operations, and achieve high production efficiency, good guiding effect, The effect of high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

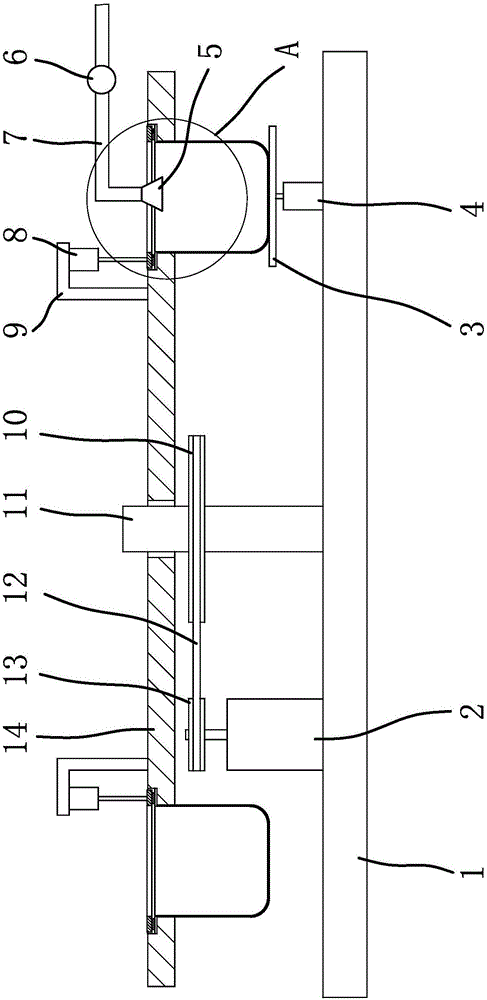

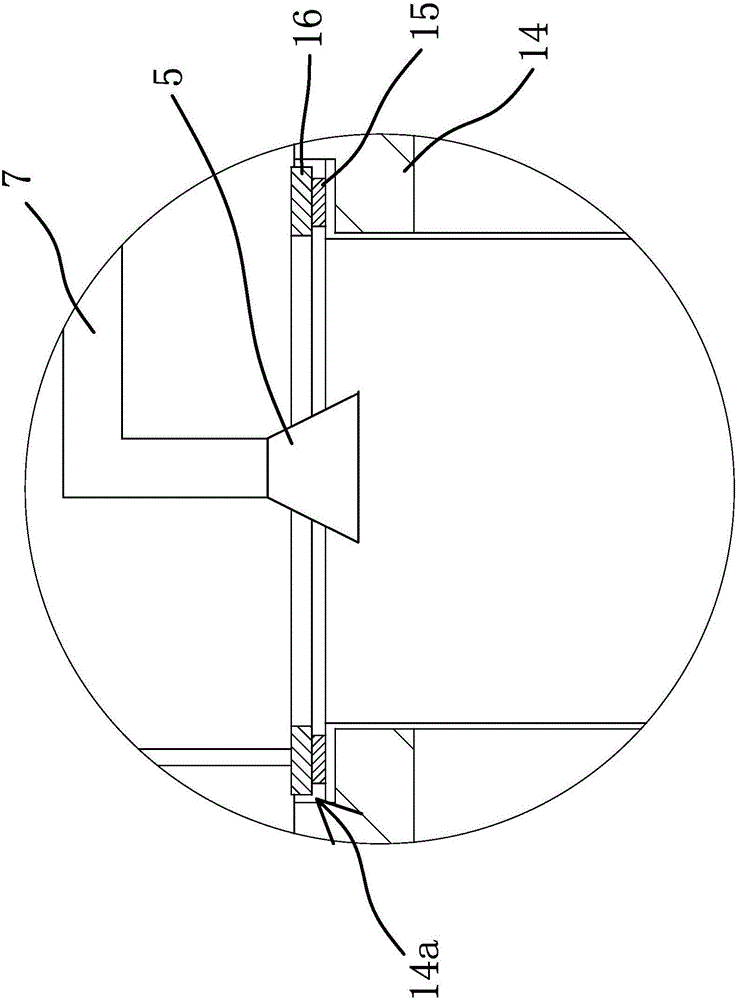

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0035] The production process of the aluminum-plastic panel comprises the following steps:

[0036] a. Pour the PE material into the preheating mixer through the feeding device for preheating, the ratio of polyethylene to color masterbatch is 1000:3, and then suck it into the hopper of the extruder by the vacuum suction machine and enter the extruder The sheet is extruded by a T-shaped touch head;

[0037] b. The temperature of the sheet is 220-230°C. The adhesive film is melted by the temperature of the PE sheet. The PE sheet and the two layers of adhesive film and the two layers of aluminum coil enter two sets of thermal compound rollers at the same time. The melted adhesive film connects the PE sheet with the two layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com