Bamboo chemimechanical pulp bioenzyme pretreatment method

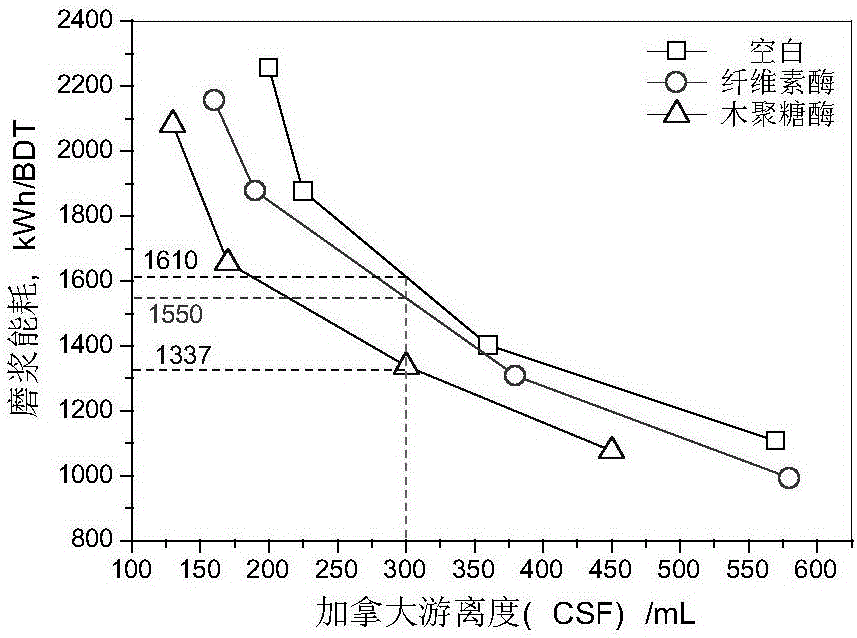

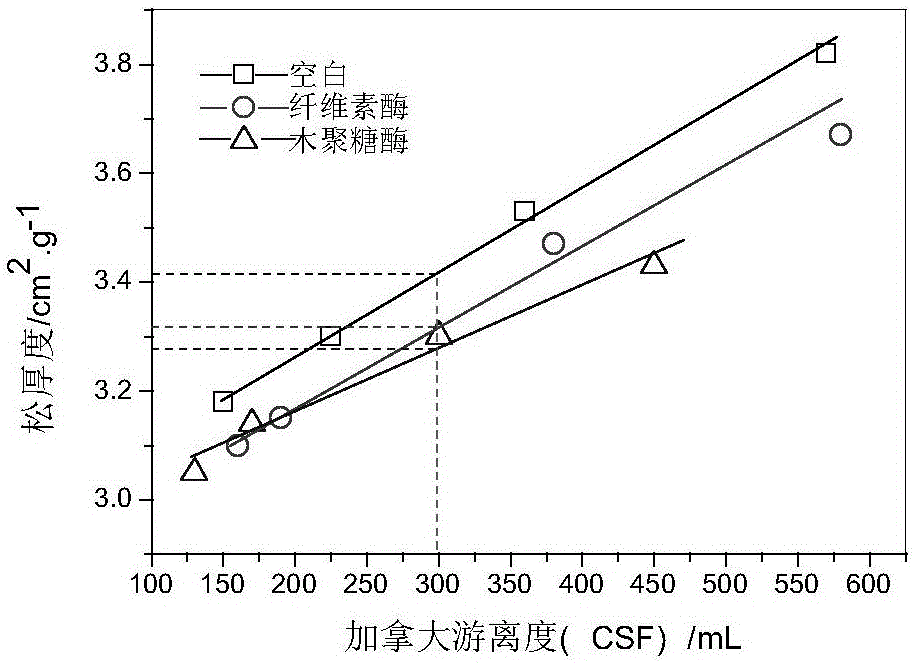

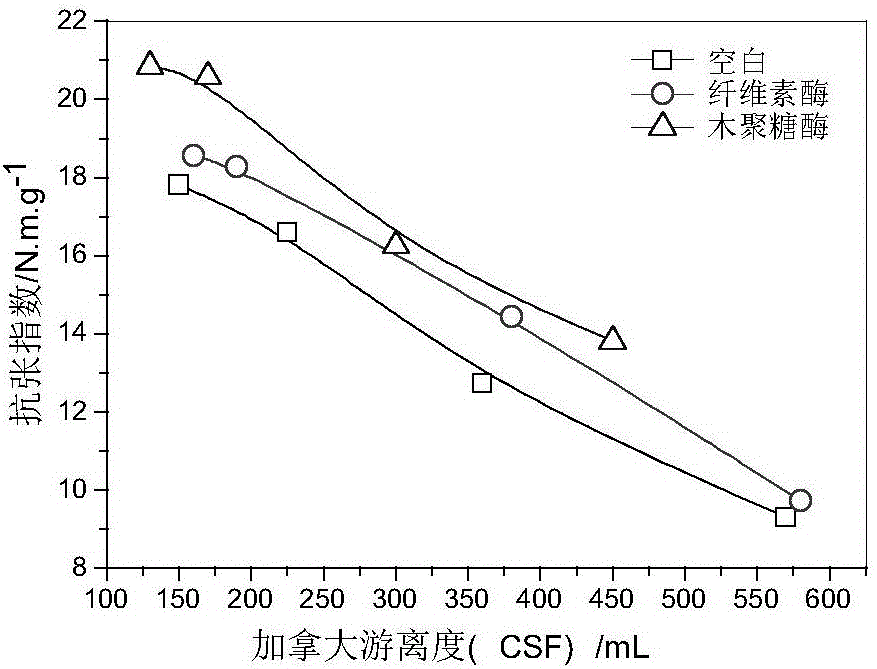

A chemical-mechanical and biological enzyme technology, applied in the field of papermaking industry, achieves the effect of improving tensile index and bursting index, decreasing tearing index and reducing power consumption of refining pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below through specific examples.

[0021] Experimental procedure: After the bamboo slices are screened by TMI bamboo slices, the qualified bamboo slices are washed with hot water, and sent to the steaming chamber for pre-steaming at normal pressure. The pre-steaming temperature is 105°C, and the time is 15 minutes. Perform the first stage of screw extrusion (compression ratio 4:1, the same below), add biological enzymes to the material after extrusion, perform biological enzyme pretreatment, perform high temperature inactivation after completion, wash and dehydrate, and perform the first stage of chemical pre-impregnation, After the first stage of impregnation is completed, the material is washed and dehydrated, and the second stage of chemical pre-impregnation is carried out. After the second stage of impregnation, use The high-consistency disc refiner performs the first stage of high-consistency atmospheric pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com