Method and system for confirming non-Newtonian fluid injection speed in laboratory experiment

A non-Newtonian fluid and injection velocity technology, applied in the field of oilfield development laboratory experiments, can solve the problems of convincing limitations of results, influence of oil displacement effect evaluation, single determination method of injection velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

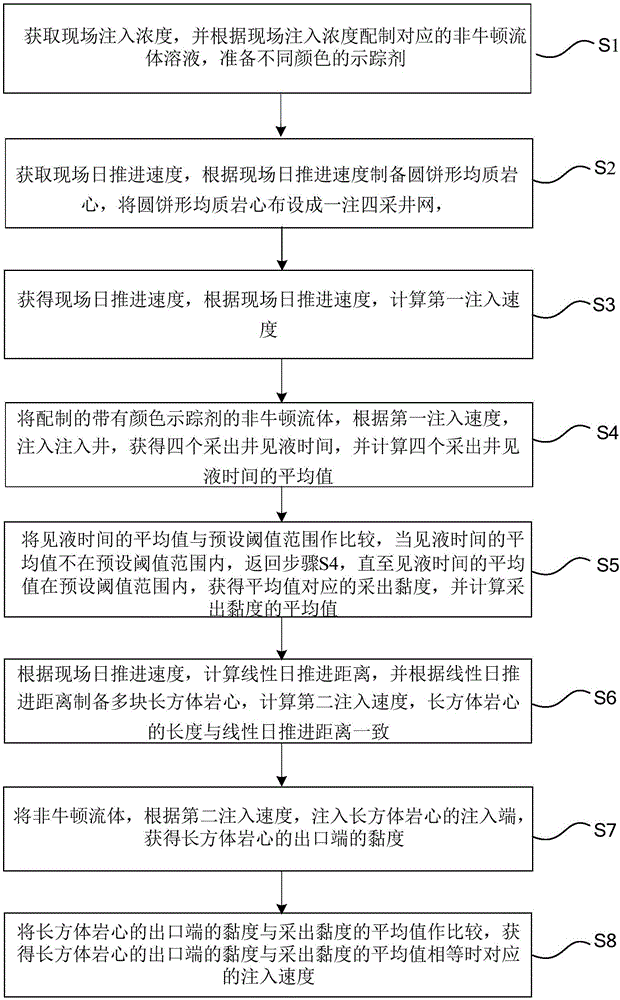

[0077] figure 1 A flow chart of a method for determining the injection velocity of a non-Newtonian fluid in an indoor experiment provided by the first embodiment of the present invention is shown. Such as figure 1 As shown, the method for determining the injection velocity of the non-Newtonian fluid in the indoor experiment according to the first embodiment of the present invention includes:

[0078] Step S1, obtain the on-site injection concentration, prepare the corresponding non-Newtonian fluid solution according to the on-site injection concentration, and prepare tracers of different colors;

[0079] Step S2, obtain the site’s daily advancing speed, prepare circular cake-shaped homogeneous cores according to the site’s daily advancing speed, and arrange the circular cake-shaped homogeneous cores into a one-injection and four-production well pattern, which consists of one injection well and four production wells. Composition of production wells, injection wells are arrang...

Embodiment 2

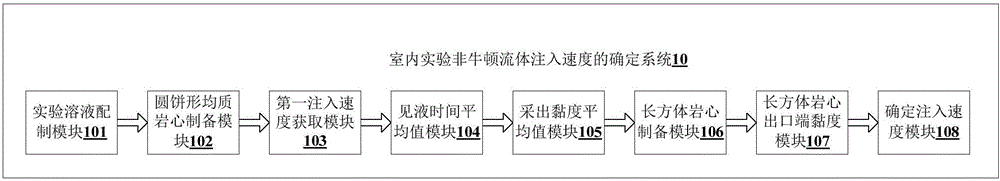

[0111] figure 2 A schematic diagram of a system for determining the injection velocity of a non-Newtonian fluid in an indoor experiment provided by the second embodiment of the present invention is shown. Such as figure 2 As shown, the indoor experiment non-Newtonian fluid injection velocity determination system 10 according to the second embodiment of the present invention includes:

[0112] The experimental solution preparation module 101 is used to obtain the on-site injection concentration, prepare the corresponding non-Newtonian fluid solution according to the on-site injection concentration, and prepare tracers of different colors;

[0113] The circular pie-shaped homogeneous core preparation module 102 is used to obtain the on-site daily advance speed, prepare the circular cake-shaped homogeneous core according to the on-site daily advance speed, and arrange the circular cake-shaped homogeneous core into a well network with one injection and four productions, one inj...

Embodiment 3

[0145]In view of the fact that the injection-production wells in the polymer flooding block of Daqing Oilfield advance 1 meter per day, the indoor experimental injection rate is determined, and the method and system for determining the indoor experimental non-Newtonian fluid injection rate of the present invention are described in detail in combination with the specific indoor experimental conditions and experimental data. illustrate.

[0146] 1. Prepare a polymer solution with a concentration of 1000mg / L, and prepare tracers of 7 colors, which are red, yellow, blue, green, pink, brown, and orange. These tracers have no effect on the viscosity of the polymer solution. obvious impact;

[0147] 2. Prepare circular cake-shaped cast rock cores and cuboid cast rock cores for simulation experiments;

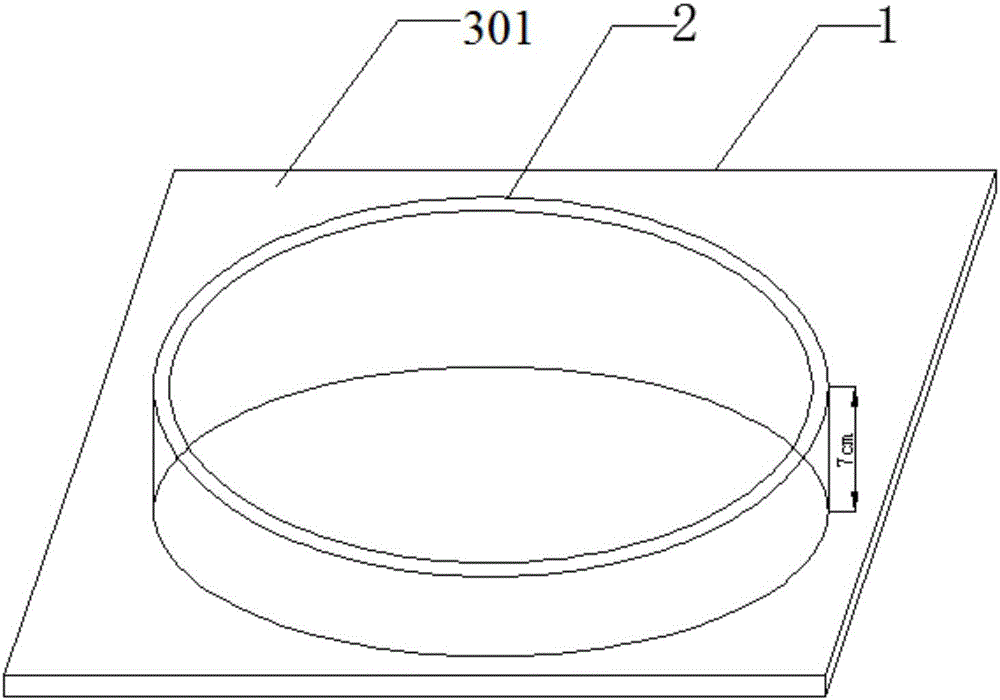

[0148] 1), preparing a round cake-shaped light slab core 6 and casting;

[0149] Advance 1 meter every day on the spot, then the radius 1m of the prepared round cake shape light slab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com