Vine-like forage chopping and extruding machine

A technology for extruders and fodder, applied to cutting equipment, agricultural machinery and tools, applications, etc., can solve the problems of inconvenient, inconvenient cleaning, time-consuming and labor-intensive, etc., and achieve convenient operation, compact structure, and high nutritional value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

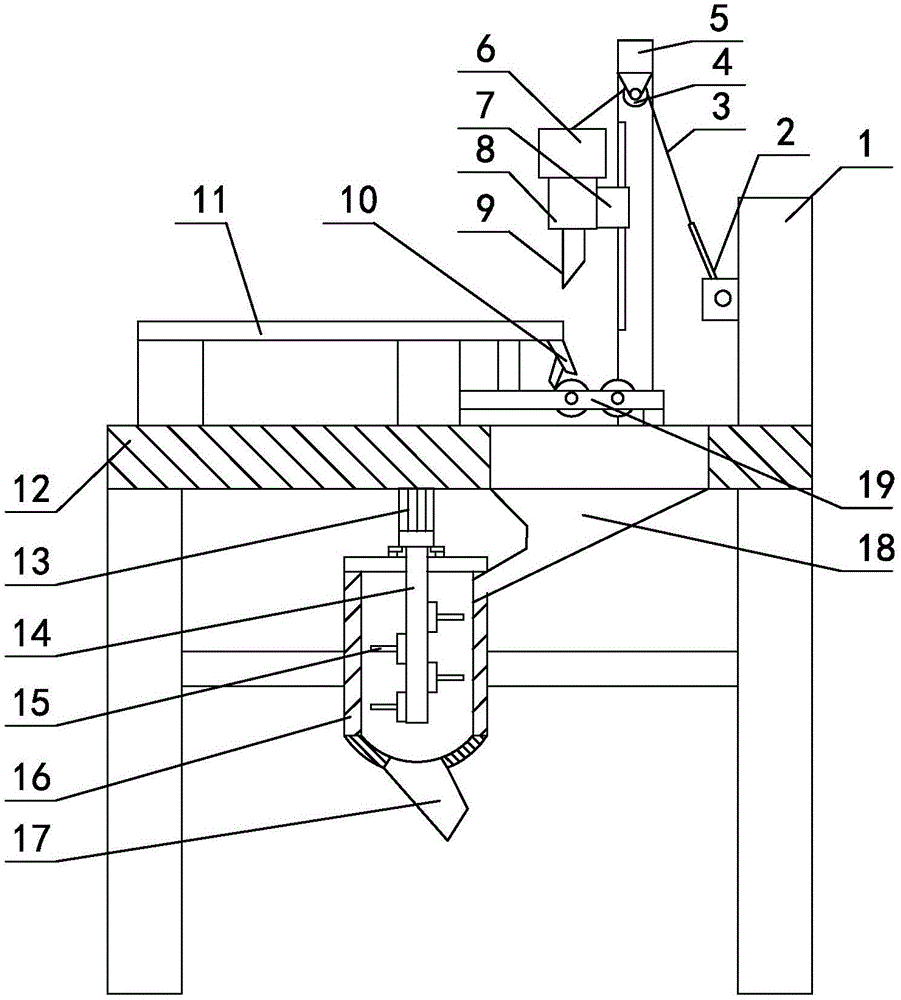

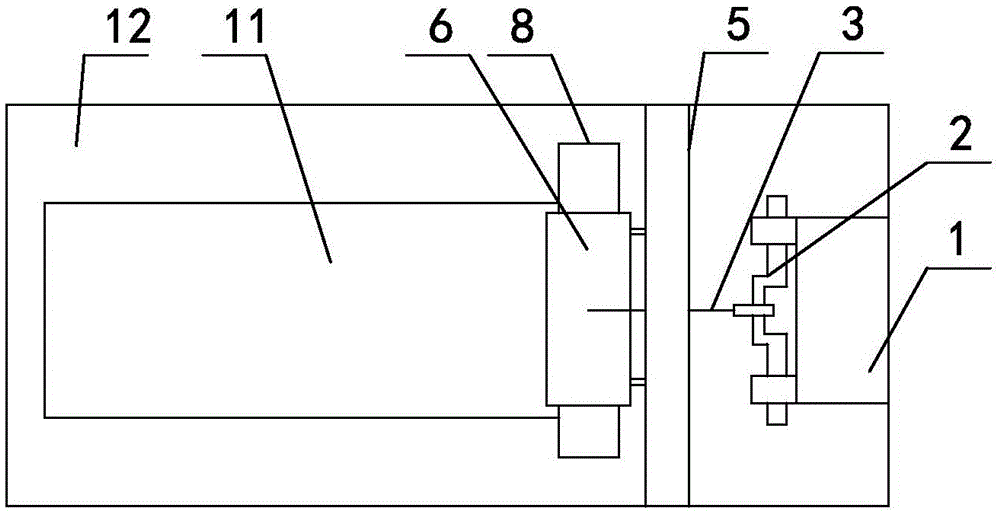

[0023] Such as figure 1 , figure 2 As shown, the rattan forage chopping and extruding machine includes a workbench 12, on which a cutting plate 11 is horizontally arranged, and a movable knife that cooperates with the right end of the cutting plate 11 to cut up and down is arranged on the right end of the cutting plate 11 9. The moving knife 9 is connected with a drive mechanism. On the workbench 12 below the cutting plate 11 and the moving knife 9, a discharge channel 18 is arranged. The discharge channel 18 is connected with a chopping tank 16, and the chopping tank 16 is installed on the In the lower part of the workbench 12, a cutting assembly is installed in the chopping tank 16, and a crushing material outlet 17 is provided at the bottom of the chopping tank 16, and a conveyor plate 10 for feeding is provided at the blanking place at the right end of the cutting plate 11. Just below the lower end of the plate 10 is provided with a set of squeeze rollers 19 for squeezin...

Embodiment 2

[0027] On the basis of Embodiment 1, the distance between the cutting blade 15 and the inner wall of the shredding tank 16 is changed to 30 mm; the shortest distance from the crank mounting bracket 1 to the right end of the cutting plate 11 is changed to 1000 mm.

[0028] Others are the same as embodiment one.

Embodiment 3

[0030] On the basis of Embodiment 1, the distance between the cutting blade 15 and the inner wall of the shredding tank 16 is changed to 25 mm; the shortest distance from the crank mounting bracket 1 to the right end of the cutting board 11 is changed to 800 mm.

[0031] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com