Building garbage color sorting system

A sorting system and construction waste technology, applied in sorting and other directions, can solve the problems affecting the sorting accuracy of the color sorter, unstable quality, slow sorting speed, etc., to achieve a simple and reliable overall structure, reduce production costs, and easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

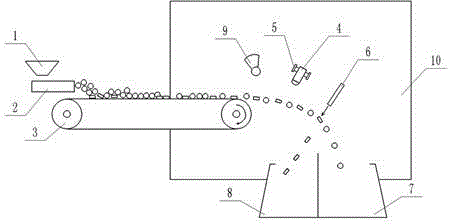

[0014] see figure 1 , the construction waste mixture enters the vibrating feeder (2) with a certain amount of feed under the control of the unloading buffer bin (1), and falls to the belt conveyor (3) under the vibration of the vibrating feeder (2). ), move forward along the belt conveyor (3), then fall from the belt conveyor (3), and enter the observation area of the image acquisition system in the color sorting box (10), the CCD imaging device (4) will The construction waste mixture is photographed and imaged, and a digital signal output is formed, which is processed through the information processing and control system to determine the material to be selected, and generates a control signal to control the action or working status of the jet apodization system (6). During image acquisition and signal processing, the construction waste mixture continues to fall and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com