A rolling method for producing ultra-thin strip steel in a cold-rolled six-high single-stand reversing rolling mill

A cold-rolled strip, single-stand technology, used in rolls, metal rolling, metal rolling, etc., can solve the problem of not introducing rolling regulations, and achieve the effect of optimizing the speed of the unit and reducing energy and power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is described in detail.

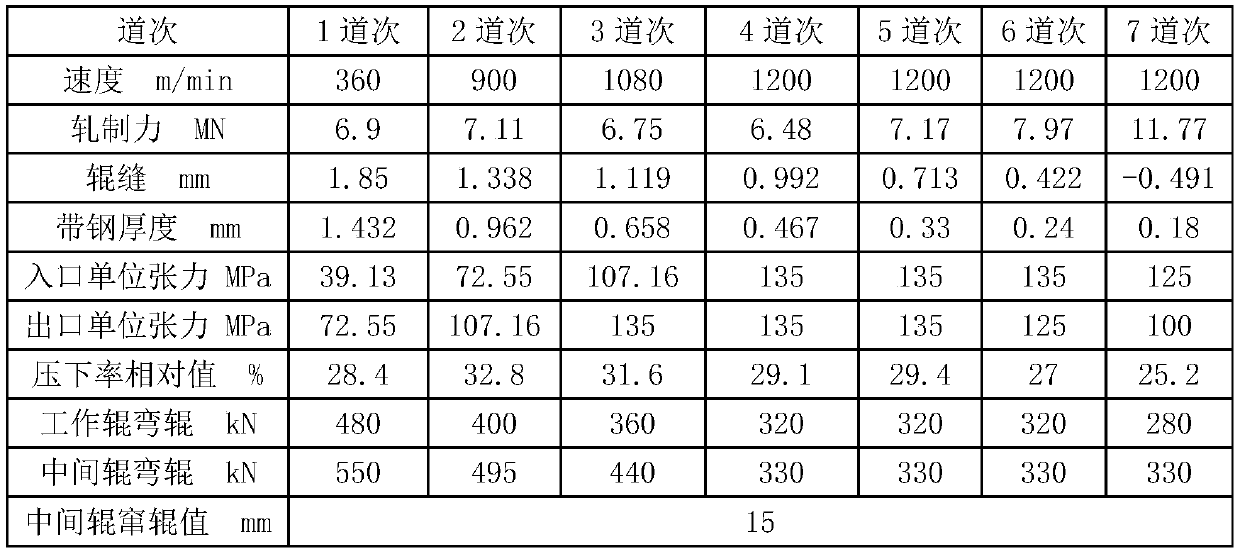

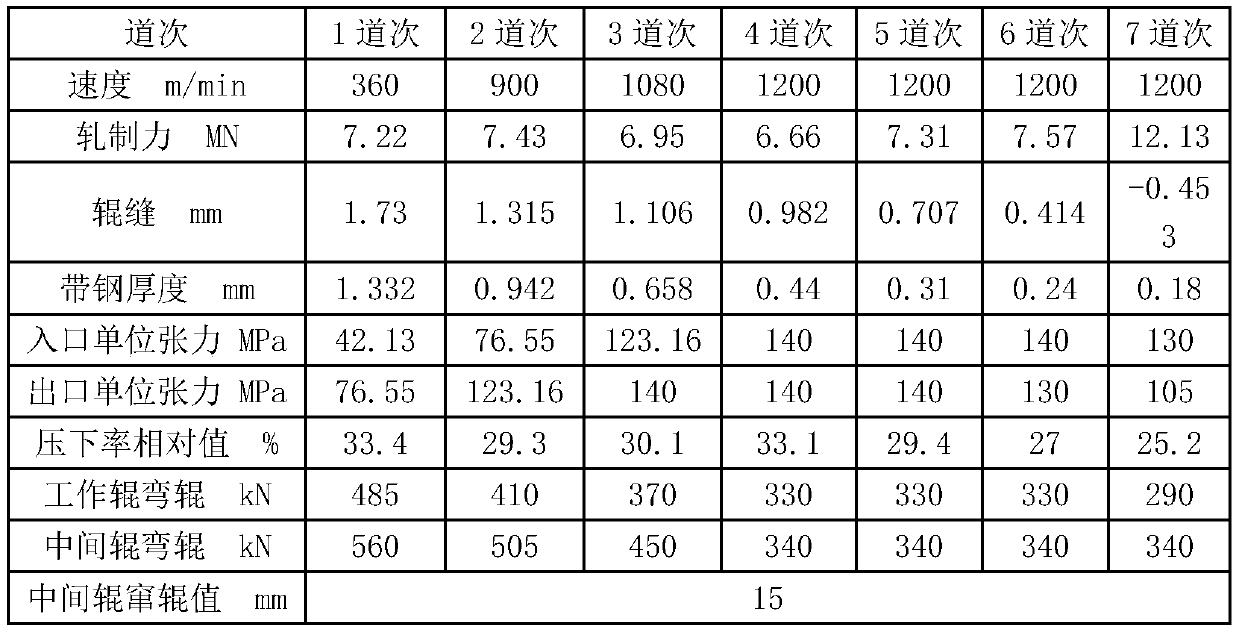

[0017] (1) Taking carbon steel SPCC steel as an example, rolling with a large compression ratio, the product is rolled from a raw material thickness of 2.0mm to a finished product thickness of 0.18mm, the strip width is 1050mm, and the total compression ratio is 91%, reaching the same level of steel The limit value of the compression ratio.

[0018] The unit adopts the motor power distribution mode, and the absolute values of reduction ratios from the first pass to the seventh pass are 31.2%, 25.81%, 16.71%, 10.5%, 7.55%, 4.89%, and 3.34%, respectively.

[0019] The unit tension from the first pass to the seventh pass is set as follows: the first pass: the entrance tension is 39.13MPa, the exit tension is 72.55MPa; the second pass: the entrance tension is 72.55MPa, the exit tension is 107.16MPa; the third pass : Entry tension 107.16MPa, exit tension 135MPa; fourth pass: entry tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com